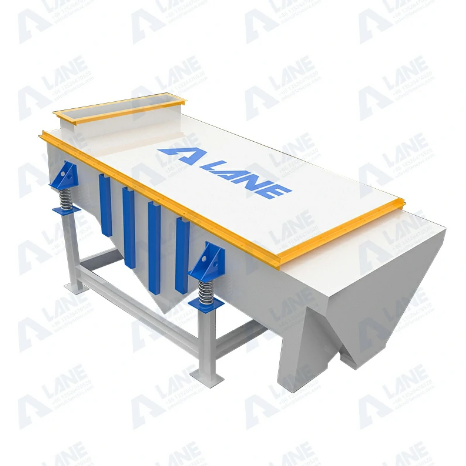

Vibration Screen Machine

A Vibration Screen Machine is an industrial screening device used to separate materials based on particle size. It operates by vibrating a screen or mesh surface, causing materials to move across the screen and allowing particles of the appropriate size to pass through while larger particles are retained. In fertilizer production, it is used to ensure uniformity and quality by sorting granules or powders based on size before packaging or further processing.

In modern fertilizer production, ensuring the right particle size and quality of the final product is essential. Screening machines play a vital role in this process, and among them, the Vibration Screen Machine stands out as a highly efficient and reliable solution. Vibration Screen Machine is designed to meet the demanding needs of fertilizer manufacturers, ensuring the precise separation of materials by particle size and contributing to the overall quality of the product.

Key Feature

High Screening Efficiency: The machine utilizes a powerful vibrating motor that ensures the efficient movement of materials across the screen, allowing for high-precision screening and separation of particles.

Multiple Screening Layers: The Vibration Screen Machine can be configured with multiple layers of screens, allowing for the sorting of materials into several different size categories in one pass. This flexibility is ideal for fertilizer producers who need to meet specific particle size requirements.

Durable Construction: Built to handle the abrasive nature of fertilizer materials, the Vibration Screen Machine is constructed with high-quality, wear-resistant materials that ensure long-term durability even under continuous operation.

Customizable Mesh Sizes: The machine can be fitted with screens of various mesh sizes, allowing producers to customize the screening process based on the specific needs of their fertilizer products. This adaptability ensures precise screening for a wide range of materials.

Low Noise and Vibration Damping: Designed to operate with minimal noise, the Vibration Screen Machine is equipped with vibration dampening features that reduce both operational noise and stress on surrounding equipment, ensuring a safer and more comfortable working environment.

Easy Maintenance and Cleaning: The machine is designed for easy access to all components, allowing for quick maintenance and cleaning. This reduces downtime and ensures continuous operation in high-volume production lines.

Energy Efficiency: LANE Group’s Vibration Screen Machine is engineered to consume minimal energy while maintaining high performance, contributing to lower operating costs and supporting sustainable production practices.

Application

Granular Fertilizer Screening: The primary application is in screening granular fertilizers, such as NPK or organic fertilizers. It ensures that only particles of the desired size proceed to the next stage of production, contributing to a uniform and high-quality product.

Powder Screening: In some fertilizer production processes, powdered materials need to be screened to remove impurities or oversized particles. The Vibration Screen Machine efficiently handles powder screening, ensuring that only the finest particles are used in the final product.

Waste Material Separation: The machine can also be used to separate waste materials from the production line, ensuring that only high-quality, usable material is processed further. This helps reduce waste and increase overall production efficiency.

Post-Production Quality Control: After granulation or drying, the Vibration Screen Machine is used to check the quality of the fertilizer by screening out any oversized particles or contaminants, ensuring that the final product meets industry standards.

Advantage

Improved Product Quality: The machine’s high screening efficiency ensures that only particles of the desired size pass through, contributing to the production of high-quality, uniform fertilizers that meet market standards.

Increased Production Efficiency: By quickly and efficiently separating materials based on size, the Vibration Screen Machine helps streamline production processes, reducing the need for manual sorting and improving overall throughput.

Reduced Waste and Reprocessing: The machine’s precision ensures that only high-quality materials move forward in the production line, reducing the need for reprocessing and minimizing waste. This helps lower production costs and increases the efficiency of raw material usage.

Low Operational Costs: With its energy-efficient design and low maintenance requirements, the Vibration Screen Machine helps reduce operational costs, making it a cost-effective solution for fertilizer producers.

Versatility in Material Handling: The Vibration Screen Machine’s customizable mesh sizes and multiple screening layers make it versatile enough to handle a wide range of materials, from powders to granules, and across various stages of production.

About LANE

Latest Articles & Tips

More-

02/13

Turnkey Fertilizer Plant Solutions: The Key to Streamlined Fertilizer Production

read more -

10/15

Nourishing Crops, Sustaining Growth: The Role of Sulphate of Ammonium in Agriculture

read more -

09/23

Improving Efficiency in Di Calcium Phosphate Production with Modern Equipment

read more -

01/28

read more