UV Photooxygen Machine

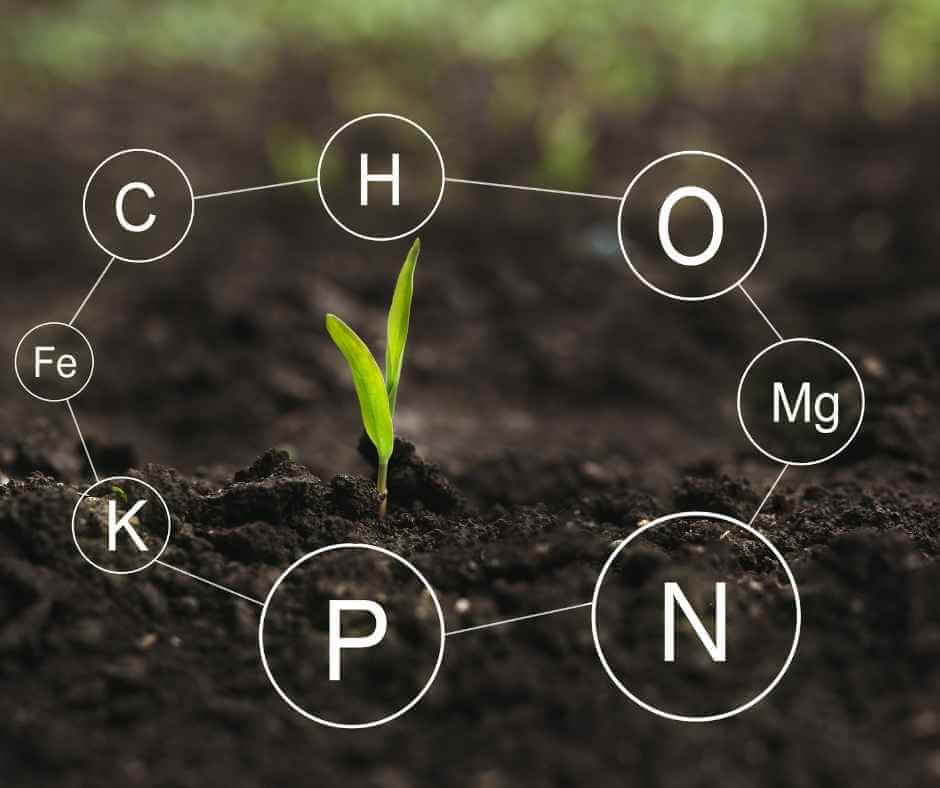

Phosphate fertilizer production is a complex process that involves the handling of various chemicals and by-products, some of which can release harmful emissions into the environment. Controlling and purifying these emissions is crucial to ensure compliance with environmental regulations and to protect the surrounding community.

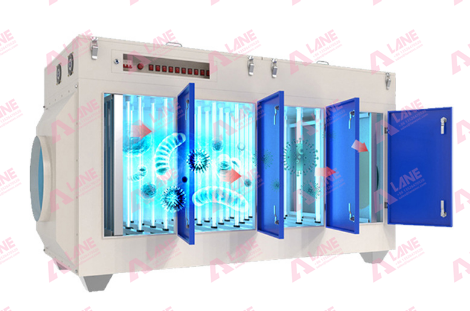

The UV Photooxygen Machine is an advanced air purification system that utilizes ultraviolet (UV) light and photooxygen oxidation to break down and neutralize harmful pollutants, particularly volatile organic compounds (VOCs) and other hazardous gases. This technology is highly effective in treating the emissions generated during the phosphate fertilizer production process, ensuring that the air released is clean and safe.

Key Feature

LANE UV Photooxygen Machine is specifically designed to meet the needs of the phosphate fertilizer industry. Here are some of the key features that make it an essential component in this sector:

- Effective VOC Treatment: Phosphate fertilizer production can generate significant amounts of VOCs, which are harmful to both the environment and human health. The UV Photooxygen Machine efficiently targets and breaks down these compounds, converting them into harmless substances such as water and carbon dioxide.

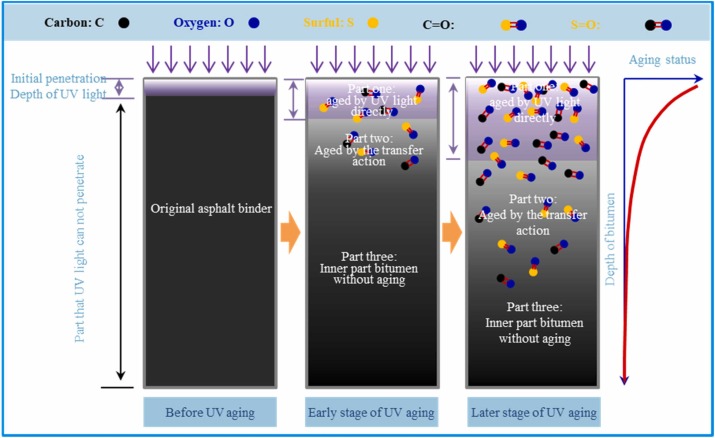

- Advanced UV Technology: The machine is equipped with high-intensity UV lamps that generate powerful ultraviolet light, which initiates the photooxidation process. This process not only breaks down pollutants but also sterilizes the air, reducing the presence of bacteria and other microorganisms.

- High Purification Efficiency: LANE Group’s UV Photooxygen Machine offers high purification efficiency, capable of removing up to 99% of harmful gases from the emissions. This ensures that the air released from the production facility meets stringent environmental standards.

- Low Energy Consumption: Despite its powerful performance, the UV Photooxygen Machine is designed to be energy-efficient, reducing operational costs while maintaining high levels of effectiveness.

- Durable Construction: The machine is built to withstand the harsh conditions of industrial environments, with corrosion-resistant materials that ensure long-lasting durability and reliable operation.

- Easy Maintenance: With a user-friendly design, the UV Photooxygen Machine is easy to maintain, featuring accessible components that simplify routine inspections and servicing.

Working Principle

Application

Phosphate fertilizer production involves several stages, including the reaction of phosphate rock with sulfuric acid to produce phosphoric acid, followed by the granulation and drying of the fertilizer. During these processes, various emissions are generated, including VOCs, sulfur compounds, and other hazardous gases. The UV Photooxygen Machine is integrated into the production line to treat these emissions effectively.

- Emissions Control in Reaction Stage: During the initial reaction stage, where phosphate rock is treated with sulfuric acid, gases such as sulfur dioxide and other pollutants are released. The UV Photooxygen Machine is used to capture and neutralize these emissions, ensuring that only clean air is released into the environment.

- Air Purification in Granulation and Drying: The granulation and drying stages also generate dust and VOCs. The UV Photooxygen Machine is positioned to treat the air before it exits the production facility, maintaining a safe and compliant operation.

Benefits

Implementing the UV Photooxygen Machine in phosphate fertilizer production offers several key benefits:

- Environmental Compliance: By effectively treating harmful emissions, the UV Photooxygen Machine helps manufacturers comply with strict environmental regulations, avoiding fines and potential shutdowns.

- Improved Air Quality: The machine ensures that the air released from the production facility is free from harmful pollutants, contributing to better air quality for workers and the surrounding community.

- Cost-Effective Operation: With its low energy consumption and minimal maintenance requirements, the UV Photooxygen Machine provides a cost-effective solution for air purification.

- Enhanced Safety: The reduction of hazardous gases in the production environment leads to a safer workplace, protecting employees from potential health risks.

If you want to know more details, Contact Us!

Latest Articles & Tips

More-

09/09

read moreGlobal Potassium Sulfate Demand Growth: The Importance of Sulphate of Potash Production Line Equipment Selection

-

01/22

read more -

10/16

read moreReducing Costs, Increasing Yields: The Benefits of SSP Bulk Fertilizer Lines

-

09/26

read moreTransforming Rock into Riches: Inside the World of Phosphate Fertilizer Production Line