TSP Production Machine: Practical Guide to Triple Super Phosphate Manufacturing

A TSP production machine is used to manufacture triple super phosphate fertilizer by reacting phosphate rock with phosphoric acid. Compared with SSP, TSP contains a much higher concentration of available phosphorus, making it suitable for intensive agriculture and phosphorus-deficient soils.

From an industrial perspective, TSP production requires stricter control over raw materials, reaction conditions, and curing time. A reliable TSP production machine focuses on stable chemical conversion rather than high nominal capacity.

What Is a TSP Production Machine?

A TSP production machine refers to the core equipment and processing system used in triple super phosphate manufacturing. Its main function is to convert finely ground phosphate rock into water-soluble phosphorus fertilizer through phosphoric acid acidulation.

Unlike SSP systems that use sulfuric acid, TSP production machines rely on phosphoric acid, which results in a higher P₂O₅ content in the final product. This difference significantly affects equipment selection and process control.

Most TSP production machines are installed as complete production lines rather than simple standalone units.

Key Features of the TSP Production Line

1. Streamlined Production Process

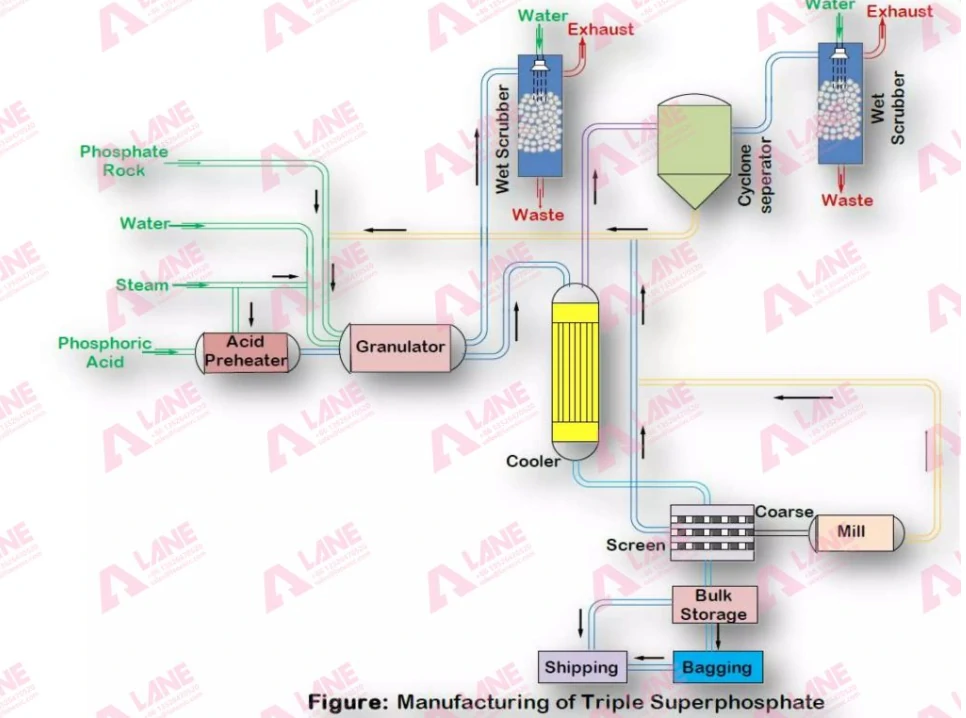

The TSP production line is engineered to efficiently convert phosphate rock into TSP fertilizer. The process involves the chemical reaction of phosphate rock with concentrated phosphoric acid, resulting in a product that is rich in phosphorus.

2. High-Quality Granulation

The granulation process is a critical step in the production of TSP. The line is equipped with advanced granulators that ensure the fertilizer is produced in uniform granules, making it easy to apply in the field and improving its effectiveness.

3. Advanced Drying and Cooling Systems

After granulation, the TSP granules undergo drying and cooling. The rotary dryer removes excess moisture, while the rotary cooler stabilizes the granules, ensuring they maintain their integrity during storage and transportation.

4. Precision Screening and Packaging

The production line includes a vibrating screen that ensures the granules are of consistent size. Any oversized or undersized particles are removed, resulting in a product that meets strict quality standards. The automatic packing machine then packages the granules efficiently, ready for distribution.

5. Environmental Control Systems

The TSP production line is equipped with dust and emission control systems, including cyclone dust collectors and scrubbers. These systems minimize environmental impact by capturing dust and controlling emissions, ensuring compliance with environmental regulations.

The Triple Superphosphate Production Line is an essential asset for producing high-quality phosphate fertilizer. Its advanced technology, efficient production process, and commitment to environmental sustainability make it a reliable and effective solution for the agricultural industry. By investing in a TSP production line, manufacturers can meet the growing demand for high-phosphorus fertilizers, contributing to the global effort to enhance food production and agricultural sustainability.

Why TSP Fertilizer Requires Specialized Production Equipment

TSP fertilizer offers high nutrient concentration, but this also increases production complexity. The reaction between phosphate rock and phosphoric acid is more sensitive to raw material quality and mixing efficiency.

Key reasons specialized TSP production machines are required include:

Higher phosphorus concentration requirements

More precise acidulation control

Longer curing and stabilization periods

Stricter quality specifications

Higher expectations for product uniformity

These factors make equipment reliability critical for long-term plant operation.

TSP Fertilizer Production Process Explained

- Raw Material Preparation: Phosphate rock is finely ground and mixed with phosphoric acid.

- Chemical Reaction: The mixture is processed in reactors where the phosphate rock reacts with phosphoric acid, forming TSP.

- Granulation: The TSP is granulated into uniform particles using advanced granulation equipment.

- Drying and Cooling: The granules are dried and cooled to remove moisture and stabilize the product.

- Screening and Packaging: The product is screened for consistency and then packaged for shipment.

Main Equipment in a TSP Production Machine System

A complete TSP production machine system typically includes:

Phosphate rock crusher and grinder

Phosphoric acid storage and dosing system

Curing area or curing system

Dust collection and ventilation system

Equipment material selection is especially important due to corrosive process conditions.

Key Factors Affecting TSP Product Quality

Several operational factors influence TSP fertilizer quality:

Phosphate rock grade

Phosphoric acid concentration

Mixing uniformity

Curing duration

Moisture control

Stable operation reduces reprocessing rates and improves product consistency.

Environmental and Safety Considerations

TSP production involves acidic materials and fine dust. Proper environmental and safety management is essential.

Common measures include acid-resistant equipment, dust collection systems, proper ventilation, and operator safety training. These measures help ensure compliance with environmental regulations and safe plant operation.

Integration with Granulation and Compound Fertilizer Lines

The TSP production machine can be integrated with granulation systems or compound fertilizer plants. In such configurations, TSP serves as a high-phosphorus raw material for blended or granulated fertilizers.

This integration allows manufacturers to diversify product offerings and improve raw material utilization.

Maintenance and Operational Considerations

Routine inspection and maintenance are critical for stable operation. Acid pipelines, mixers, and curing areas require regular checks to prevent corrosion and blockages.

Preventive maintenance reduces downtime and extends equipment service life. Consistent monitoring is often more effective than frequent adjustments.

Choosing the Right TSP Production Machine Supplier

When selecting a TSP production machine supplier, manufacturers should prioritize practical experience over theoretical capacity claims.

A reliable supplier should provide:

Process design based on raw material characteristics

Durable equipment materials

Installation and commissioning support

Operator training and long-term technical service

These factors directly affect startup success and production stability.

Conclusion

A TSP production machine is essential for manufacturing high-concentration phosphorus fertilizer. Proper equipment selection, stable process control, and adequate curing time are key to achieving consistent product quality. With professional design and reliable operation, TSP production offers strong long-term value for fertilizer manufacturers.

For internationally recognized definitions and quality benchmarks related to phosphate fertilizers, manufacturers can refer to the FAO fertilizer specifications for phosphate fertilizers, which provide standardized classifications and technical references used in global fertilizer production and trade.

Call to Action

If you are planning to install or upgrade a TSP production machine, early technical evaluation can reduce risks and operating costs. Professional process support helps ensure stable production and consistent fertilizer quality over the long term.

Ready to choose the right fertilizer solution? Contact LANE today to learn more about .

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Send a message to us