TSP Fertilizer Production Line: Process, Equipment, and Plant Design

A TSP fertilizer production line is designed to manufacture triple superphosphate fertilizer through controlled chemical reactions and stable granulation processes. As a high-concentration phosphate fertilizer, TSP is widely used in agriculture due to its high P₂O₅ content and good solubility. For industrial producers, the efficiency and stability of the production line directly affect product quality, operating cost, and long-term plant performance.

This article introduces the core process, key equipment, and plant design considerations of a TSP fertilizer production line from an engineering and manufacturing perspective.

What Is a TSP Fertilizer Production Line?

A TSP fertilizer production line is an industrial system used to convert phosphate rock into triple superphosphate fertilizer through acidulation, granulation, drying, cooling, and screening. Unlike blended fertilizers, TSP production relies on a chemical reaction between finely ground phosphate rock and phosphoric acid, which requires precise process control and stable equipment operation.

From a plant-level perspective, a well-designed TSP fertilizer production line focuses not only on output capacity, but also on production stability, material flow efficiency, and long-term operational reliability.

TSP Fertilizer Production Process

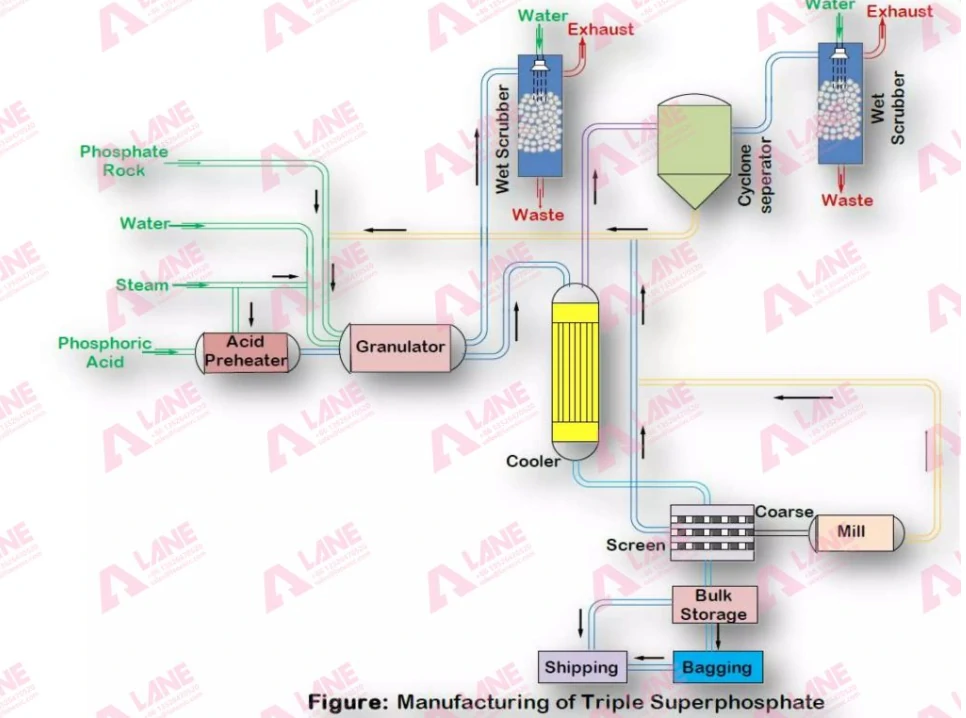

The production process of TSP fertilizer typically includes the following stages:

Raw Material Preparation

Phosphate rock is crushed and ground to a suitable particle size before entering the reaction stage. Uniform particle distribution is essential for consistent acidulation and reaction efficiency.

Chemical Reaction (Acidulation)

Phosphate rock reacts with phosphoric acid to form monocalcium phosphate, which is the main nutrient component of TSP fertilizer.

In industrial operation, reaction temperature, acid concentration, and retention time must be precisely controlled. Improper acidulation can lead to incomplete conversion or excessive free acid, which directly affects granulation stability and final product quality in a TSP fertilizer production line.

Granulation

The reacted slurry is transferred to a granulator, where it forms uniform fertilizer granules. Granulation performance is one of the most critical factors in a TSP fertilizer production line, as it directly influences product appearance, storage behavior, and downstream handling efficiency.

Drying and Cooling

After granulation, the fertilizer granules are dried to reduce moisture content and then cooled to improve mechanical strength and storage stability.

Screening and Recycling

Finished granules are screened to separate qualified products from oversized or undersized particles. Off-size materials are recycled back into the granulation system to improve raw material utilization.

According to a United Nations Environment Programme report on fertilizer production processes, the manufacture of triple superphosphate (TSP) involves acidulating phosphate rock with phosphoric acid, distinguishing it from single superphosphate production and highlighting key chemical steps in industrial fertilizer manufacturing. This authoritative overview provides a global industrial perspective on TSP production methodologies.

Key Equipment in a TSP Fertilizer Production Line

A complete TSP fertilizer production line typically includes the following major equipment:

Crushing and grinding systems for phosphate rock

Acidulation reactors or mixers

Granulators (rotary drum or other industrial granulation systems)

Rotary dryers and coolers

Screening machines and material handling conveyors

Dust collection and environmental protection systems

Each piece of equipment must be properly matched to ensure smooth material flow and stable long-term operation.

Plant Design Considerations

Process Control and Automation

Modern TSP fertilizer production lines rely on automation systems to monitor temperature, material flow rate, and reaction conditions. Stable process control improves product consistency and reduces operational risks.

Capacity Planning

Production capacity should be selected based on raw material availability, market demand, and utility conditions. In practice, plant design should balance production capacity with long-term operational stability, rather than pursuing maximum output at the expense of maintenance complexity and energy consumption.

Layout and Material Flow

A rational plant layout reduces material transfer distances and minimizes energy loss. Clear separation between reaction, granulation, and finishing sections helps improve plant-level efficiency.

Environmental Protection

Dust control and exhaust gas treatment are essential components of any industrial-grade TSP fertilizer production line. Proper environmental design supports regulatory compliance and sustainable operation.

Advantages of TSP Fertilizer

TSP fertilizer offers several advantages for agricultural application:

High phosphorus concentration

Good water solubility

Suitable for a wide range of crops

Stable nutrient release characteristics

From an industrial perspective, consistent product quality depends heavily on the reliability of the production line.

TSP Fertilizer vs Other Phosphate Fertilizers

TSP fertilizer is often compared with other phosphate fertilizers such as SSP and DAP. While all are used to supply phosphorus, their nutrient composition and manufacturing processes differ.

From a manufacturing perspective, the differences between TSP fertilizer and DAP are also reflected in the design of industrial production systems. Factors such as raw material processing, reaction control, and granulation requirements directly influence the configuration of a TSP fertilizer production line.

In practical fertilizer selection, TSP fertilizer and DAP are often discussed together due to their different nutrient compositions and application scenarios. Understanding their production background helps explain why they perform differently in agricultural use.

Frequently Asked Questions

What is the typical production capacity of a TSP fertilizer production line?

Typical TSP fertilizer production lines are designed with capacities ranging from small modular systems to large-scale industrial plants, depending on raw material availability and market demand.

Can a TSP fertilizer production line be customized?

Yes. Production lines can be configured according to capacity requirements, plant layout, and automation level to suit different project conditions.

What factors affect the stability of a TSP fertilizer production line?

Key factors include raw material quality, process control accuracy, equipment selection, and maintenance management. Stable operation depends on balanced design rather than maximum throughput.

Send a message to us