5 Reasons to Choose LANE TSP Fertilizer Production Line to Optimize Production and Quality

Triple Super Phosphate (TSP) fertilizer is an essential phosphorus source in modern agriculture, contributing to soil fertility and improved crop yields. However, producing TSP efficiently and at high quality requires specialized equipment and technology. LANE Group, a leading name in fertilizer production machinery, offers a TSP Fertilizer Production Line that not only optimizes productivity but also ensures top-tier product quality. Here are three compelling reasons to choose LANE’s TSP Fertilizer Line to elevate your production capabilities.

Reason 1: Rigorous design for efficient manufacturing

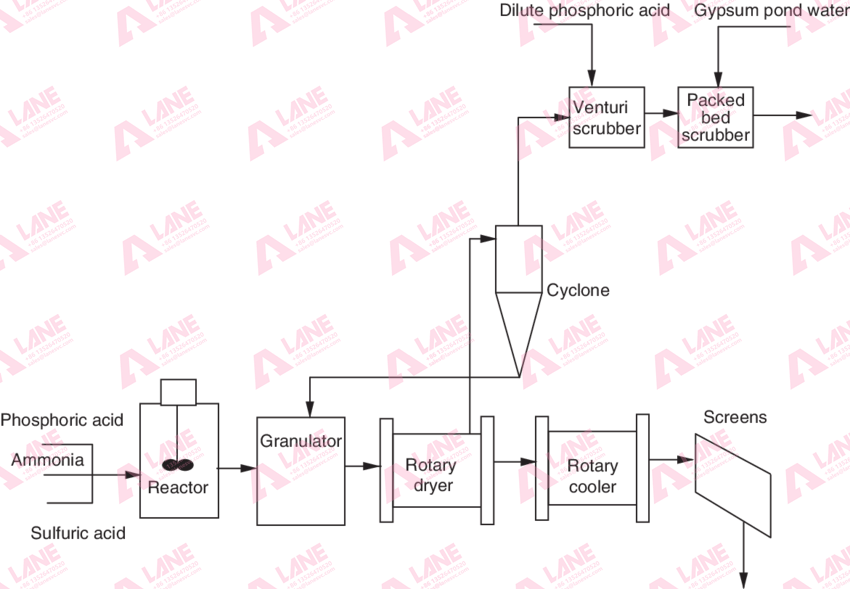

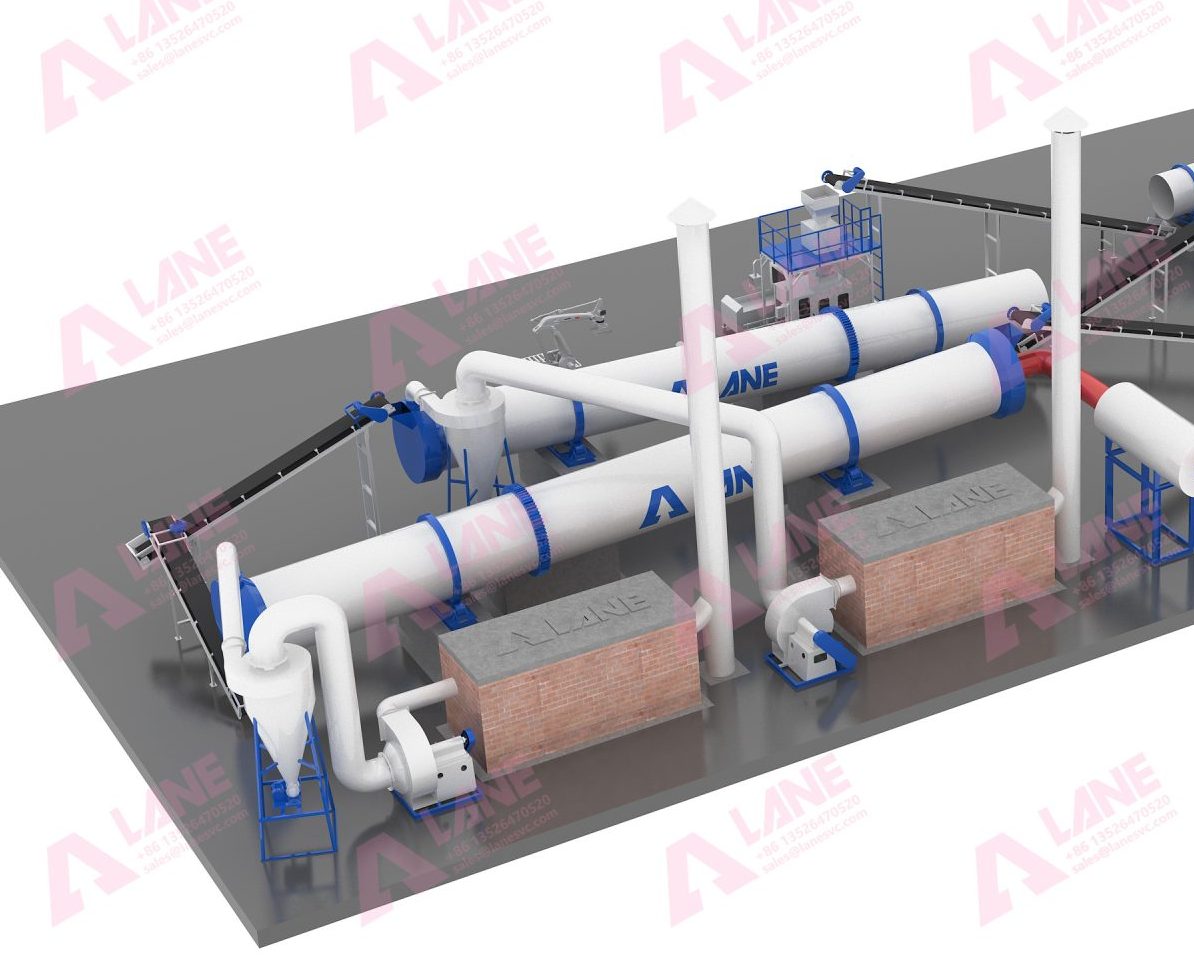

One of the primary reasons to choose the LANE TSP Fertilizer Production Line is its high production efficiency. The line is equipped with automated processes that significantly reduce the need for manual labor, speeding up the overall production process. Its ability to continuously feed raw materials and granulate them in large volumes ensures that manufacturers can produce more fertilizer in less time, which directly increases productivity.

Automation also ensures that the operation runs smoothly without unnecessary downtime, thanks to its streamlined systems for material handling, drying, and cooling. This minimizes disruptions and ensures that the TSP Fertilizer Production Line operates at optimal capacity throughout the day. Manufacturers report up to a 30% increase in production throughput compared to traditional systems.

Additionally, the LANE TSP Fertilizer Production Line is designed to minimize material wastage. Its granulation and drying systems are highly precise, ensuring that raw materials are converted into final products without excessive waste. This not only reduces raw material costs but also contributes to environmental sustainability by lowering waste generation.

Reason 2: Advanced Crushing and Reaction Systems for Higher Efficiency

One of the most critical steps in TSP Fertilizer Production Line is the reaction between phosphate rock and phosphoric acid. To ensure a high-quality product, the raw materials must be finely crushed to allow for optimal chemical reactions. LANE’s TSP Fertilizer Production Line includes an advanced rock phosphate crusher that guarantees fine and uniform grinding, ensuring higher surface area exposure for chemical reactions.

The high-efficiency reaction kettle used in LANE’s system accelerates the interaction between phosphoric acid and finely ground phosphate rock. Through innovative stirring and temperature control, this system enhances the speed and completeness of the reaction, leading to a higher yield of TSP in less time. This efficient process helps increase overall productivity and improves the consistency and quality of the final product.

Reason 3: State-of-the-Art Granulation Technology for Uniform Product Quality

The quality of granules produced by a fertilizer line is crucial, as it affects how easily the fertilizer can be applied in the field and how efficiently it delivers nutrients to crops. The LANE TSP Fertilizer Production Line is equipped with advanced granulators that ensure uniform granulation. Each granule produced is consistent in size and shape, making it easier to store, transport, and apply.

Uniform granules also improve the efficiency of nutrient delivery in agricultural applications. When fertilizer granules are of consistent size, they dissolve evenly in the soil, ensuring that phosphorus is distributed uniformly across the field. This is particularly important for Triple Superphosphate fertilizers, which have a high concentration of phosphorus — a critical nutrient for plant growth, root development, and increased crop yields.

The line also incorporates sophisticated drying and cooling technologies to stabilize the granules, further ensuring that the product remains of high quality even during long storage periods. This durability helps prevent granule breakage or deterioration, ensuring that the product retains its efficacy over time.

Reason 4: Energy-Efficient Drying and Cooling Systems to Maximize Output

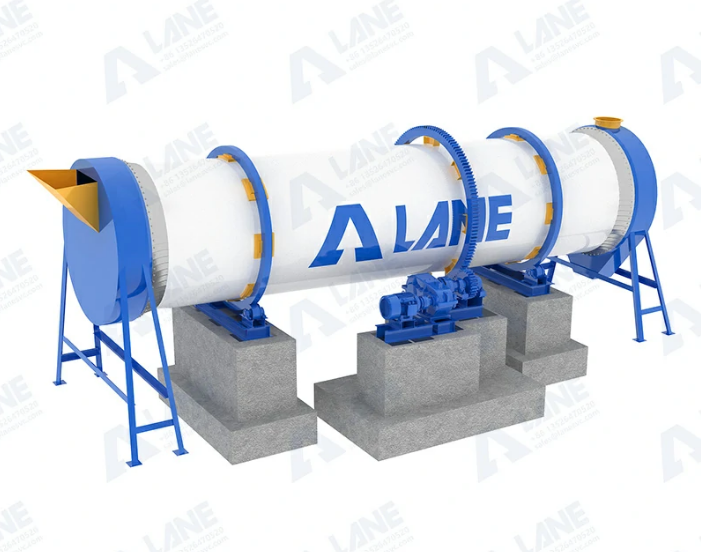

A significant challenge in TSP Fertilizer Production Line is the energy-intensive drying and cooling process. After the granules are formed, they need to be dried and cooled to stabilize the product for long-term storage and transportation. LANE’s production line incorporates energy-efficient rotary dryers and coolers that use innovative heat recovery systems to reduce overall energy consumption.

By recycling heat generated during the production process, these systems drastically reduce energy costs while ensuring that the granules are dried and cooled uniformly and quickly. The improved drying and cooling technology not only enhances production speed but also ensures the integrity of the final product, preventing granule degradation during storage or transport.

Reason 5: Comprehensive Support and Customization

Every production environment is unique, which is why LANE Group offers customizable solutions for its TSP fertilizer production lines. The LANE team works closely with clients to understand their specific production requirements, offering tailored configurations of machinery and equipment.

In addition to customization, LANE also provides comprehensive technical support throughout the installation and operational phases. Their engineers are available to offer guidance on machine setup, operation, and maintenance, ensuring that production lines are optimized for long-term performance. This level of support not only reduces potential production delays but also improves the overall efficiency of your operations.

Conclusion

Choosing the right TSP fertilizer production line can significantly impact the success of your manufacturing operations. LANE Group’s TSP fertilizer line offers advanced technology, energy efficiency, high production capacity, and exceptional support and customization options. By investing in LANE’s solution, manufacturers can enhance both the quality and quantity of their fertilizer products, positioning themselves for long-term success in the competitive agricultural market.

Optimize your production and take your fertilizer manufacturing to the next level with LANE Group’s TSP Fertilizer Production Line.

About LANE’s Service

Send a message to us