Triple Superphosphate Production Line: A Step-by-Step Guide to High-Efficiency TSP Fertilizer Production

What Is a Triple Superphosphate Production Line?

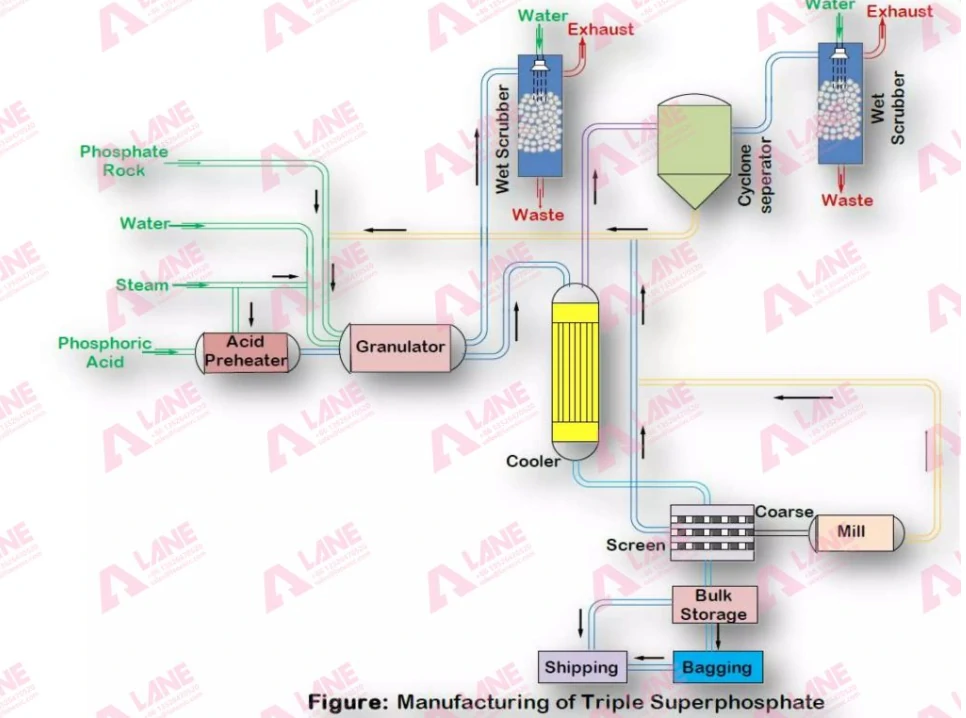

A Triple Superphosphate Production Line is an integrated system that uses phosphoric acid to chemically react with finely ground phosphate rock, producing calcium dihydrogen phosphate — a highly water-soluble form of phosphorus.

Compared with Single Superphosphate (SSP), TSP offers:

Much higher P₂O₅ content (typically 45–48%)

No gypsum by-product

Faster nutrient release

Lower transportation and application costs per unit of phosphorus

Because of these advantages, TSP production lines are widely adopted by large-scale fertilizer plants and export-oriented manufacturers.

As you explore the process of designing and operating a Triple Superphosphate Production Line, it’s helpful to contextualize the fertilizer’s role in crop nutrition and agricultural systems. The Global Agriculture Triple Superphosphate Fertilizer guide offers detailed insights into TSP’s agronomic characteristics, water solubility, and field applications, supporting a practical understanding of product applications

Raw Material Preparation: The Foundation of Stable Production

Phosphate Rock Crushing and Grinding

The production process begins with phosphate rock, which must be crushed and ground to a controlled fineness. Proper particle size ensures:

- Complete reaction with phosphoric acid

- Stable slurry formation

- Reduced acid consumption

Excessively coarse particles reduce reaction efficiency, while overly fine powder may affect material handling and granulation stability.

Moisture and Quality Control

Moisture content and impurity levels must be strictly controlled. Consistent raw material quality is critical for maintaining uniform reaction conditions throughout the Triple Superphosphate Production Line.

Acidulation Reaction: The Core Chemical Process

The acidulation stage is the heart of the Triple Superphosphate Production Line.

Finely ground phosphate rock reacts with concentrated phosphoric acid

The reaction occurs in a dedicated reactor or mixer

Precise control of acid-to-rock ratio is essential

Key control parameters include:

Reaction temperature

Acid concentration

Residence time

Proper control ensures maximum phosphorus conversion, minimal residual free acid, and stable downstream processing.

Granulation: Turning Slurry into Market-Ready Fertilizer

After acidulation, the reaction material enters the granulation system.

Granulation Objectives

Convert semi-liquid material into solid granules

Achieve uniform particle size

Improve flowability and application performance

Disc granulators or drum granulators are commonly used, depending on plant capacity and product specifications. Granulation quality directly affects drying efficiency and final product appearance.

Drying and Cooling: Ensuring Product Stability

Fresh TSP granules contain excess moisture and heat, which must be removed before storage.

Drying Stage

Rotary dryers reduce moisture to safe storage levels

Controlled airflow prevents over-drying and nutrient loss

Cooling Stage

Cooling machines lower granule temperature

Prevents caking during storage and transportation

This stage is essential for maintaining physical strength and shelf stability of TSP fertilizer.

Screening, Recycling, and Packaging

Screening System

Granules are screened to separate:

- Qualified product

- Oversized particles (crushed and recycled)

- Fines (returned to granulation)

This closed-loop system improves raw material utilization and production efficiency.

Automatic Packaging

Final TSP fertilizer is weighed, bagged, and sealed using automatic packaging machines, ensuring:

- Accurate weight control

- Clean loading

- Improved labor efficiency

Process Optimization in a Triple Superphosphate Production Line

To achieve long-term stable operation, attention must be given to:

Automated control systems for acidulation and granulation

Consistent raw material feeding

Proper dust collection and gas treatment

Preventive equipment maintenance

Advanced automation helps reduce human error, stabilize product quality, and lower operating costs.

Environmental and Safety Considerations

Modern Triple Superphosphate Production Lines are designed with environmental protection in mind, including:

Dust collection systems

Acid mist scrubbing units

Wastewater recovery and reuse

These systems help plants meet environmental regulations while improving overall production safety.

Conclusion

A well-designed Triple Superphosphate Production Line is not just a set of machines, but a complete chemical and mechanical system. From phosphate rock preparation to final fertilizer packaging, each step must be carefully controlled to ensure high phosphorus conversion, stable granulation, and consistent product quality.

By following a structured process and adopting modern automation and environmental technologies, manufacturers can build an efficient, reliable, and competitive TSP fertilizer production facility.

Send a message to us