Triple Superphosphate Production Line: 7 Key Steps in TSP Manufacturing

What Is a Triple Superphosphate Production Line?

A triple superphosphate production line is an industrial system designed to convert phosphate rock into high-concentration phosphorus fertilizer through acidulation and granulation. Unlike compound fertilizer plants, TSP production focuses on phosphorus conversion efficiency rather than nutrient blending.

Triple superphosphate typically contains around 46% P₂O₅, making it one of the most concentrated straight phosphate fertilizers. The production line must ensure complete reaction, stable granulation, and consistent product quality.

From an engineering perspective, simplicity and reliability are key advantages of a triple superphosphate production line.

Raw Material Requirements and Acidulation Principles

Phosphate rock quality directly affects the performance of a triple superphosphate production line. Parameters such as P₂O₅ content, particle size distribution, and impurity levels must be evaluated during project planning.

The core chemical step is acidulation, where phosphate rock reacts with phosphoric acid. Reaction efficiency depends on acid concentration, contact time, and temperature control.

Proper acidulation design ensures high phosphorus availability while minimizing unreacted residues that can affect downstream processing.

Acidulation Reactor and Process Control

The acidulation reactor is the heart of the triple superphosphate production line. Its design must provide sufficient mixing and residence time to allow the reaction to proceed toward completion.

Temperature and moisture control are critical. Excess moisture increases drying load, while insufficient moisture leads to incomplete reaction. Stable reactor operation improves material consistency before granulation.

Compared with DAP systems, TSP acidulation is less sensitive, allowing for simpler control strategies and lower automation requirements.

Curing Stage and Reaction Completion

Curing is a defining feature of the triple superphosphate production line. After acidulation, material must be allowed to cure so that the reaction between phosphate rock and acid fully completes.

Curing can occur in piles, curing halls, or controlled enclosures. Time requirements vary depending on raw material quality and process conditions.

Effective curing improves product solubility, reduces free acid, and enhances granulation stability. Skipping or shortening this stage often leads to unstable product performance.

Granulation System Design for TSP

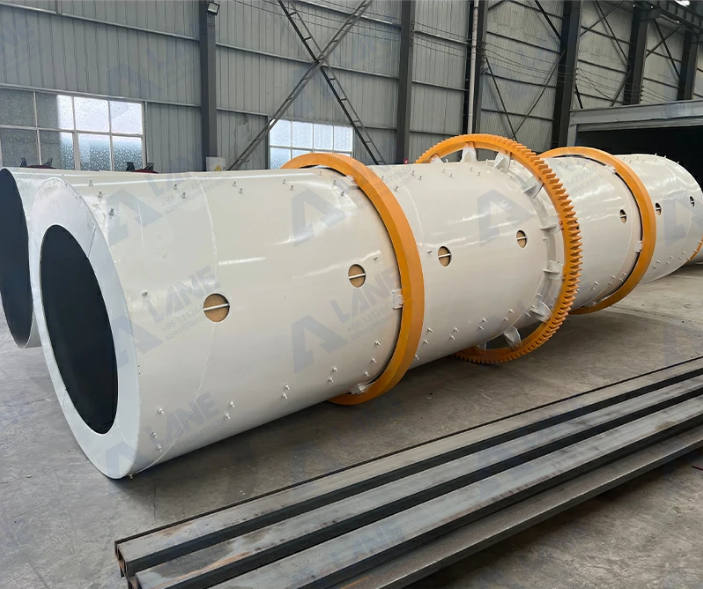

Granulation improves handling, storage, and application of triple superphosphate. Most triple superphosphate production lines use rotary drum granulators due to their stable operation and capacity flexibility.

Granulation parameters must be adjusted based on cured material characteristics. Moisture balance, recycle ratio, and granulator speed influence granule size distribution.

Compared with compound fertilizer granulation, TSP granulation is more forgiving, resulting in lower recycle loads and smoother operation.

Drying and Cooling Requirements

Drying removes excess moisture to achieve acceptable storage stability. In a triple superphosphate production line, drying temperatures are moderate to avoid degrading phosphorus availability.

Rotary dryers are commonly used due to their robustness and adaptability. Proper airflow and residence time control reduce energy consumption while maintaining product quality.

Cooling stabilizes granules before screening and packaging. Adequate cooling improves granule strength and reduces caking during storage.

Screening, Recycling, and Product Size Control

Screening equipment ensures that finished TSP granules meet size specifications. Undersized and oversized particles are separated and returned to the granulation system.

Efficient screening reduces recycling load and improves net output. Screen selection and layout influence both product quality and plant throughput.

A well-designed triple superphosphate production line balances recycling to support granulation without overloading equipment.

Environmental Control and Safety Management

Environmental systems are essential for modern triple superphosphate production lines. Dust, acidic vapors, and fluoride emissions must be properly managed.

Dust collectors, scrubbers, and ventilation systems are integrated into the plant layout. Compared with ammonia-based fertilizers, TSP production involves fewer safety hazards.

Effective environmental control supports regulatory compliance and long-term operational stability.

Automation and Operational Simplicity

Automation levels in a triple superphosphate production line are typically moderate. Basic monitoring of temperature, feed rates, and equipment status is sufficient for stable operation.

Lower automation requirements reduce capital investment and simplify maintenance. This makes TSP plants attractive for regions with limited technical workforce.

Operational simplicity contributes to lower operating cost and faster commissioning.

Maintenance and Long-Term Plant Performance

Maintenance planning should be incorporated during the design phase. Wear parts such as mixer linings, granulator shells, and dryer components require periodic inspection.

Easy access to equipment reduces downtime and improves safety. Spare parts standardization simplifies inventory management.

A properly maintained triple superphosphate production line delivers consistent output and predictable operating costs over time.

Conclusion

For a recognized industry overview of phosphate fertilizer categories and production practices, refer to the phosphate fertilizer production reference by IFA, which includes detailed classification and discussion of products like triple superphosphate in the global fertilizer industry.

A triple superphosphate production line offers a practical and reliable solution for high-concentration phosphate fertilizer production. Its simpler process, lower operating complexity, and reduced safety risks make it suitable for both new and expanding fertilizer producers.

By focusing on acidulation efficiency, curing effectiveness, and stable granulation, manufacturers can achieve consistent product quality and long-term operational success. Careful engineering design and realistic process planning remain the foundation of a successful triple superphosphate production line.

Ready to choose the right fertilizer solution? Contact LANE today to learn more about .

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Send a message to us