Triple Superphosphate Production Line

The Triple Superphosphate (TSP) Production Line is an advanced system designed to produce high-quality phosphate fertilizer, which is essential for enhancing agricultural productivity. TSP is known for its high phosphorus content, typically around 45-48%, making it a valuable fertilizer for boosting crop yields.

What We Offer:

- Production process design

- Professional technical guidance

- Equipment Customization & Manufacturing

- Overseas engineers on-site installation

- 5 Years Warranty

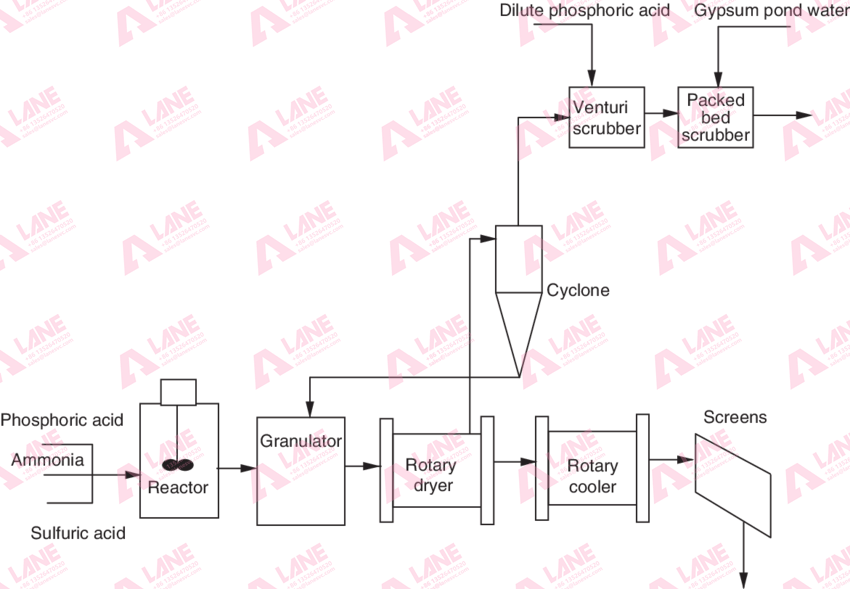

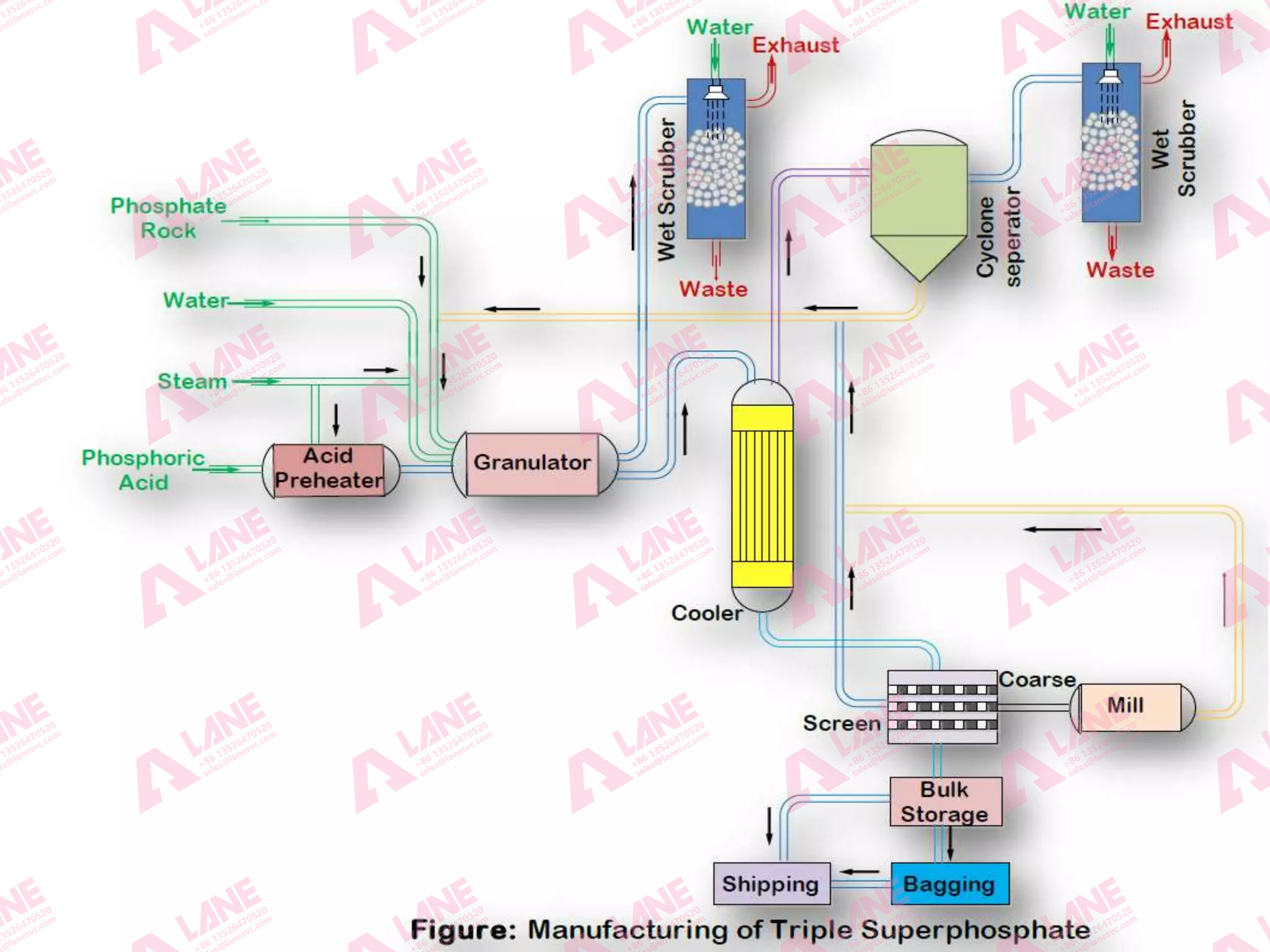

Overview of the Production Process

- Raw Material Preparation: Phosphate rock is finely ground and mixed with phosphoric acid.

- Chemical Reaction: The mixture is processed in reactors where the phosphate rock reacts with phosphoric acid, forming TSP.

- Granulation: The TSP is granulated into uniform particles using advanced granulation equipment.

- Drying and Cooling: The granules are dried and cooled to remove moisture and stabilize the product.

- Screening and Packaging: The product is screened for consistency and then packaged for shipment.

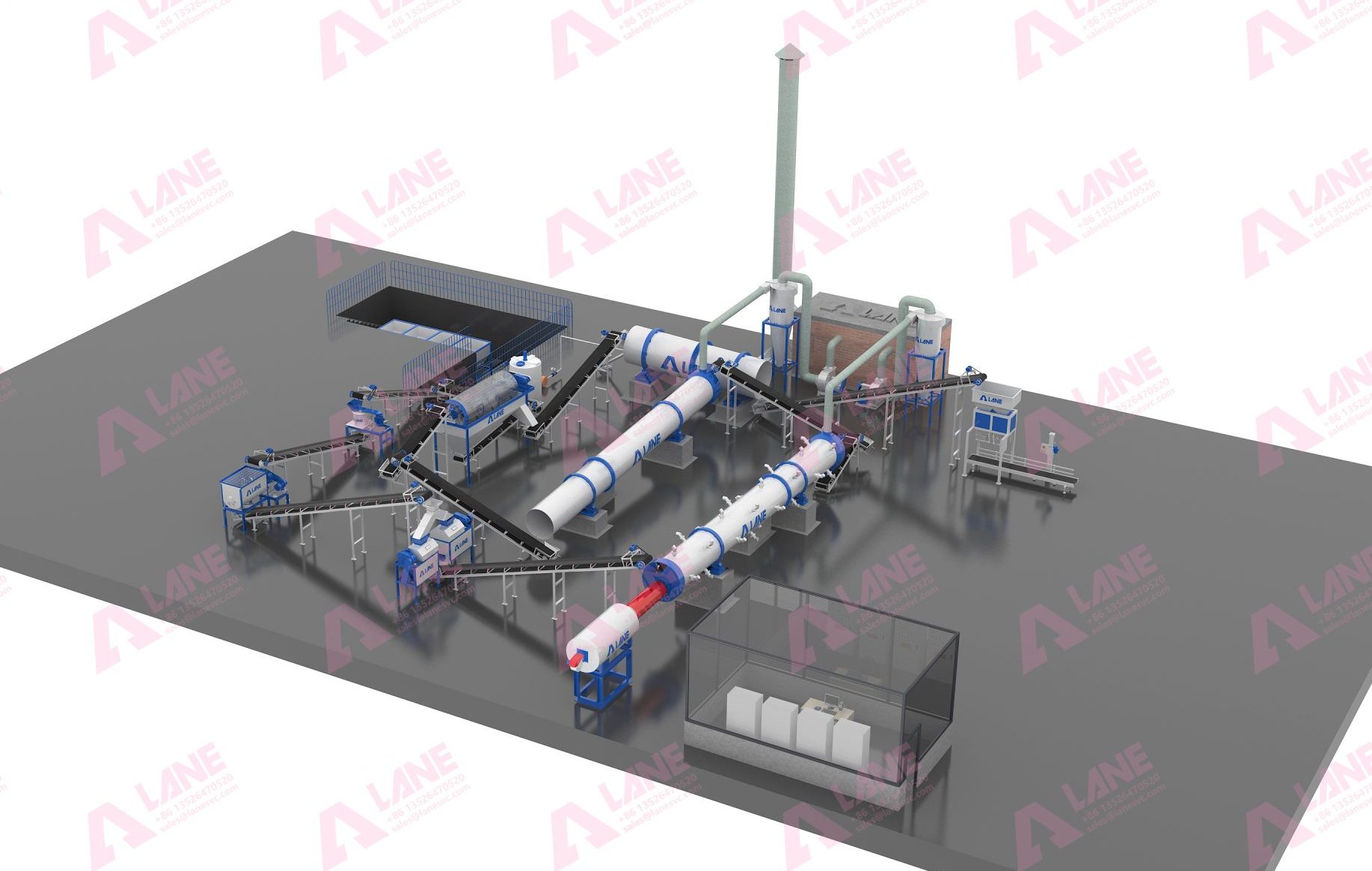

Pictures of equipment

Key Features of the TSP Production Line

1. Streamlined Production Process

The TSP production line is engineered to efficiently convert phosphate rock into TSP fertilizer. The process involves the chemical reaction of phosphate rock with concentrated phosphoric acid, resulting in a product that is rich in phosphorus.

2. High-Quality Granulation

The granulation process is a critical step in the production of TSP. The line is equipped with advanced granulators that ensure the fertilizer is produced in uniform granules, making it easy to apply in the field and improving its effectiveness.

3. Advanced Drying and Cooling Systems

After granulation, the TSP granules undergo drying and cooling. The rotary dryer removes excess moisture, while the rotary cooler stabilizes the granules, ensuring they maintain their integrity during storage and transportation.

4. Precision Screening and Packaging

The production line includes a vibrating screen that ensures the granules are of consistent size. Any oversized or undersized particles are removed, resulting in a product that meets strict quality standards. The automatic packing machine then packages the granules efficiently, ready for distribution.

5. Environmental Control Systems

The TSP production line is equipped with dust and emission control systems, including cyclone dust collectors and scrubbers. These systems minimize environmental impact by capturing dust and controlling emissions, ensuring compliance with environmental regulations.

The Triple Superphosphate Production Line is an essential asset for producing high-quality phosphate fertilizer. Its advanced technology, efficient production process, and commitment to environmental sustainability make it a reliable and effective solution for the agricultural industry. By investing in a TSP production line, manufacturers can meet the growing demand for high-phosphorus fertilizers, contributing to the global effort to enhance food production and agricultural sustainability.

Real-Life Shipping Cases of Our Products

By choosing Lane Group’s TSP production line, you will enjoy the following benefits:

Our equipment has been certified for a number of reasons and we push the belief that quality comes first.

Our customers from all over the world! We have many country-specific transactions!

If you want to know more, Contact Us!