6 Strategies to Maximize Output with a Triple Superphosphate Fertilizer Production Line

Triple superphosphate (TSP) fertilizer is a highly concentrated phosphorus fertilizer used widely in modern agriculture to enhance plant growth and boost crop yields. For producers aiming to maximize output, efficiently running a Triple Superphosphate Production Line is crucial. This essay outlines six strategies to optimize productivity, minimize waste, and ensure top-quality results from your production process.

Optimize Raw Material Management

The first step in maximizing output with a Triple Superphosphate Fertilizer Production Line is ensuring a consistent and high-quality supply of raw materials. The main component in Triple Superphosphate Fertilizer Production Line is phosphate rock, which must meet specific chemical requirements for effective conversion into phosphate fertilizer. By carefully managing the sourcing, storage, and pre-treatment of raw materials, production can be optimized in several ways:

- Sourcing High-Quality Phosphate Rock: The higher the grade of phosphate rock, the more efficiently it can be processed. Consistent quality minimizes interruptions and reduces the need for additional processing steps.

- Efficient Raw Material Storage: Proper storage solutions, such as humidity-controlled silos, can help maintain the quality of raw materials, preventing degradation due to moisture or contamination.

- Effective Pre-Treatment: Grinding the phosphate rock to the correct particle size ensures optimal acidulation and reaction with sulfuric acid, the next critical step in the Triple Superphosphate Fertilizer Production Line. This results in better chemical conversion and higher production yields.

Fine-Tune the Acidulation Process

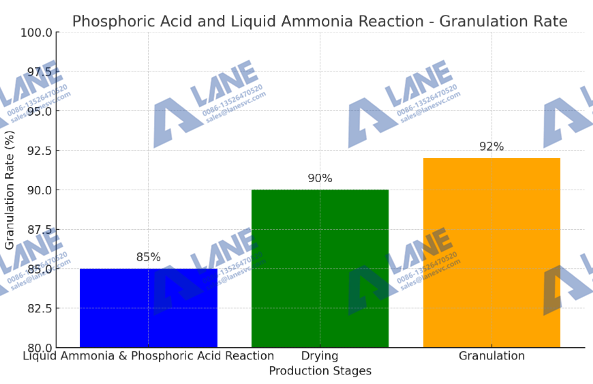

LANE Reaction Rate

Acidulation is a core phase in the Triple Superphosphate Fertilizer Production Line, where phosphate rock reacts with sulfuric acid to produce phosphoric acid, which is then used to create TSP. Maximizing output in this phase requires precise control over reaction conditions:

- Maintain Proper Acid Ratios: Ensuring the correct sulfuric acid to phosphate rock ratio is essential for maximizing the reaction yield. Deviations from the ideal ratio can lead to incomplete reactions, reducing the efficiency of the Triple Superphosphate Fertilizer Production Line.

- Monitor Temperature and Pressure: Temperature and pressure in the acidulation chamber must be optimized to maintain a steady and complete chemical reaction. Advanced monitoring systems can help keep these parameters in check, minimizing energy losses and maximizing the production rate.

- Use High-Efficiency Reactors: Modern reactors designed for uniform mixing and rapid reaction speeds can boost production output by accelerating the acidulation process, reducing downtime, and minimizing the formation of by-products.

Implement Advanced Granulation Techniques

The granulation process of the Triple Superphosphate Fertilizer Production Line is critical for producing Triple Superphosphate in the correct form for application. Poor granulation can lead to inconsistent fertilizer quality, which negatively impacts both production output and product performance. Optimizing this stage can greatly improve throughput:

- Utilize High-Efficiency Granulators: Investing in high-capacity granulators that ensure uniform granule size improves the final product’s quality. Uniformly sized granules also improve storage, handling, and application, making the end product more desirable to customers.

- Control Moisture Content: Managing moisture during granulation ensures that the material flows smoothly through the system. Overly wet or dry materials can cause blockages, reducing output. Precision moisture control allows for faster drying times and more efficient granulation.

- Add Coating Systems: A well-coated TSP granule is less prone to dusting and moisture absorption during storage. Coating systems enhance product quality while allowing for smoother production, minimizing waste during packaging and transportation.

Automate and Streamline the Production Line

Automation and streamlining processes can significantly increase the output of a Triple Superphosphate Fertilizer Production Line. By integrating automation at key points of the production process, manufacturers can reduce human error, minimize downtime, and ensure smooth operations.

- Automated Process Control: Automated systems can monitor variables such as temperature, pressure, and material flow in real-time, making immediate adjustments to keep the production line running at optimal capacity.

- Streamlined Material Handling: Automation in material transport, such as conveyor belts and automated loaders, can significantly reduce the time between different production stages. This minimizes bottlenecks and ensures a continuous, high-speed production flow.

- Predictive Maintenance: Using sensors and advanced diagnostics, predictive maintenance systems can identify potential equipment failures before they cause downtime. Regular maintenance scheduling based on data analytics prevents unexpected breakdowns, keeping output high.

Optimize Drying and Cooling Systems

After granulation, Triple Superphosphate must be dried and cooled before packaging to ensure that the product is stable and free from moisture. Proper management of this stage directly impacts the efficiency and final output of the Triple Superphosphate Fertilizer Production Line:

- Energy-Efficient Dryers: The drying process can be energy-intensive. Investing in energy-efficient rotary or fluidized bed dryers can significantly reduce energy consumption while maintaining high drying speeds. This not only maximizes production output but also reduces operational costs.

- Optimize Cooling Systems: Once the fertilizer granules are dried, they need to be cooled to prevent degradation during storage and packaging. High-efficiency cooling systems, such as rotary coolers or fluidized bed coolers, ensure a quick cooling process, allowing for higher throughput and consistent product quality.

- Monitor Moisture Levels: Over-drying or under-drying granules can affect their quality and performance in the field. Advanced moisture sensors can be installed to monitor and adjust moisture levels in real time, ensuring that the final product is within specification and reducing material wastage.

Implement a Robust Quality Control System

High-quality Triple Superphosphate is critical for maintaining a strong reputation in the market, but it also has a direct impact on production efficiency. A robust quality control system ensures that every step of the production process is aligned with performance and output goals:

- Real-Time Quality Monitoring: Modern quality control systems use sensors and laboratory analysis to monitor the composition and quality of TSP at each stage of Triple Superphosphate Fertilizer Production Line. Immediate feedback allows operators to make necessary adjustments to maintain consistent product quality.

- Batch Testing: Regular testing of finished product batches ensures compliance with industry standards and customer expectations. Quality control systems that catch subpar batches early in the process prevent wasted materials and lost production time.

- Process Optimization: Continuous improvement programs that analyze production data can identify inefficiencies and bottlenecks. By using quality control data to fine-tune the production line, manufacturers can increase yield and minimize waste.

Conclusion

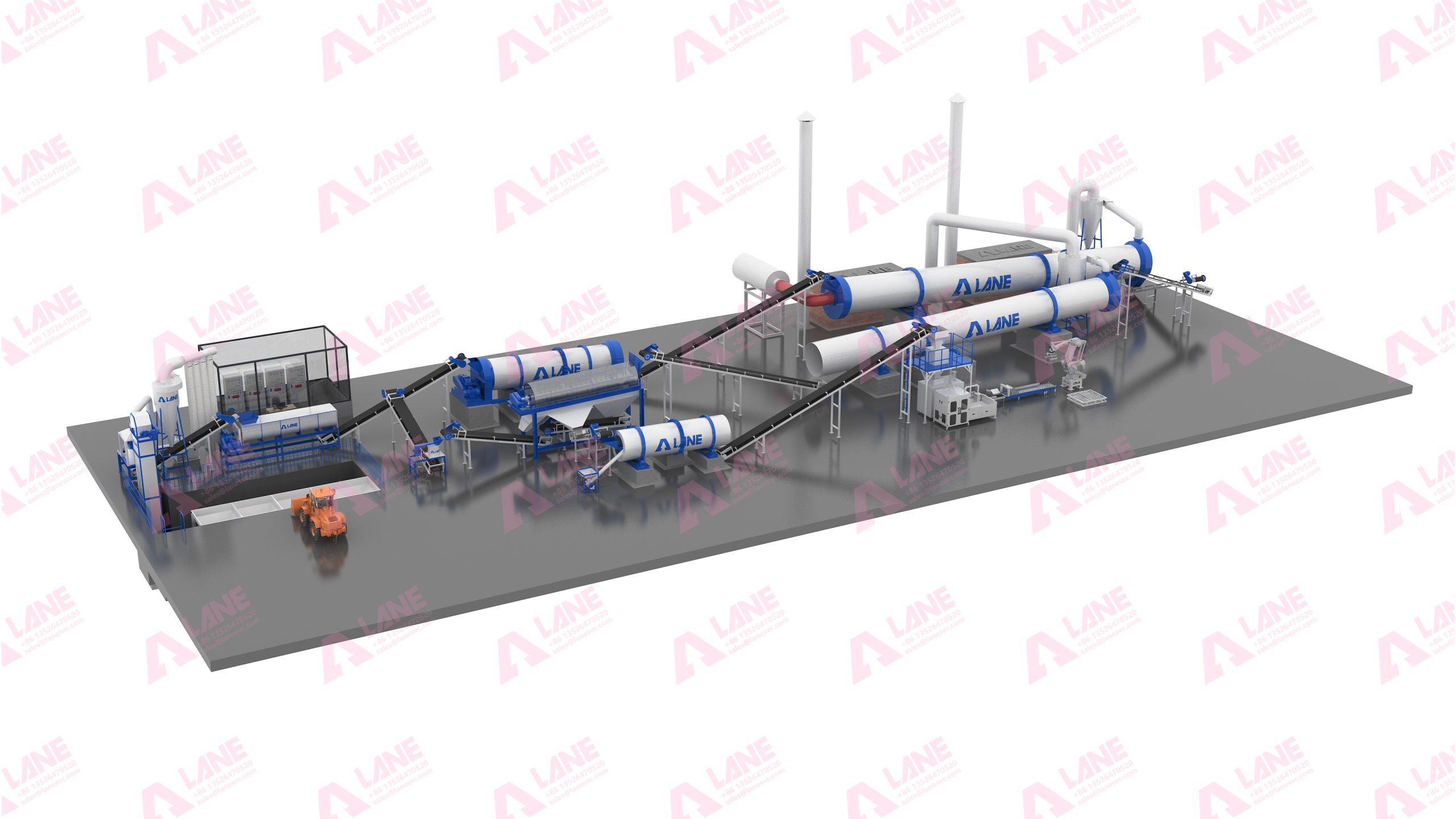

The Triple Superphosphate Fertilizer Production Line offers immense potential for producers to generate high-quality fertilizer and meet the growing demand for phosphorus-based products. By implementing these six strategies — optimizing raw material management, fine-tuning the acidulation process, advancing granulation techniques, automating the production line, optimizing drying and cooling, and establishing a robust quality control system — manufacturers can maximize output while minimizing costs and waste.

The integration of modern technology and precision control across every stage of the process ensures that your Triple Superphosphate Fertilizer Production Line operates at peak efficiency, yielding consistent, high-quality Triple Superphosphate that supports both agricultural productivity and business profitability.

Send a message to us