Top 4 Innovations in Superphosphate SSP Compound Production for LANE

The production of Superphosphate SSP Compound has long been a cornerstone in the fertilizer industry, particularly for supplying essential phosphorus to crops. However, as agriculture evolves, so does the need for advanced production techniques to enhance efficiency, product quality, and environmental sustainability. LANE, a leader in fertilizer production technology, has pioneered several innovations that are transforming the Superphosphate SSP Compound Production landscape. These innovations not only streamline the manufacturing process but also significantly boost the performance and environmental impact of the fertilizers.

Energy-Efficient Reaction Systems: Reducing Operational Costs and Environmental Impact

The core of Superphosphate SSP Compound Production lies in the chemical reaction between phosphate rock and sulfuric acid to create superphosphate fertilizer. However, this process traditionally consumes high amounts of energy, leading to both increased costs and significant environmental emissions. LANE has revolutionized this stage by introducing energy-efficient reaction systems designed to optimize the chemical process while reducing overall energy consumption.

Through advanced heat recovery mechanisms and optimized thermal management, LANE’s new systems ensure that energy used in one part of the process is repurposed to drive other stages, cutting down energy usage by as much as 20%. This not only reduces the carbon footprint of the production line but also brings down operational costs, making Superphosphate SSP Compound Production more cost-effective. Additionally, these systems reduce the release of harmful emissions, aligning production lines with international environmental regulations and sustainable agriculture goals.

Advanced Granulation Techniques: Ensuring Consistent Product Quality

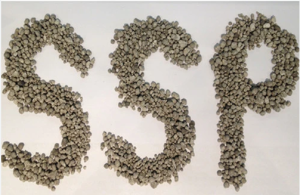

Granulation is a critical phase in the production of Superphosphate SSP Compound, as it transforms the raw mix of chemicals into uniform granules that are easy to transport, store, and apply to fields. Inconsistent granulation can lead to problems in nutrient release, impacting crop yields and overall soil health. LANE’s advanced granulation techniques address these challenges by incorporating precision control over the granulation process.

By tightly managing factors such as moisture content, temperature, and granule size, LANE ensures that each granule produced meets exacting quality standards. This leads to improved product durability and uniformity, meaning fewer breakages during transportation and better distribution of nutrients once applied to fields. The use of innovative binding agents in the granulation process further enhances granule strength, which prevents crumbling and ensures the even spread of phosphorus in the soil.

In terms of product application, these high-quality granules dissolve at the ideal rate, ensuring crops receive a steady supply of phosphorus over time. This uniform nutrient distribution boosts crop yields, making the advanced granulation process a cornerstone of modern Superphosphate SSP Compound Production.

Automated Quality Control Systems: Ensuring Precision and Reducing Human Error

Quality control is critical in ensuring that every batch of fertilizer meets stringent agricultural standards. Traditional Superphosphate SSP Compound Production methods often rely on manual checks and balances, leaving room for human error and inconsistencies. LANE has taken a forward-thinking approach by integrating automated quality control systems into their production lines, ensuring precision and consistency in every step of the process.

These automated systems use cutting-edge sensors and real-time monitoring to track variables such as nutrient concentration, particle size, moisture content, and granule strength. Data is continuously collected and analyzed to ensure that the production process remains within tight tolerances. In the event that any deviation is detected, the system can automatically adjust settings to bring the process back to optimal conditions without the need for human intervention.

By adopting these automated systems, Superphosphate SSP Compound Production lines reduce the risks associated with human error, increase production efficiency, and minimize waste. Manufacturers benefit from improved product consistency, while farmers can trust that each batch of fertilizer will perform reliably in the field, delivering predictable results for their crops.

Eco-Friendly Byproduct Management: Promoting Sustainability and Reducing Waste

One of the significant challenges in the Superphosphate SSP Compound Production process is the management of byproducts, particularly waste materials like gypsum, a common byproduct from the chemical reactions involved in producing superphosphate. Traditionally, these byproducts are seen as waste, posing disposal challenges and environmental risks. However, LANE has developed innovative solutions that turn these byproducts into valuable resources.

Through advanced recycling and reprocessing technologies, LANE has transformed waste management into an opportunity for sustainability. For instance, gypsum, which is typically discarded, can now be reprocessed and sold for use in industries such as construction or even as a soil amendment. This creates a closed-loop system where byproducts are no longer simply discarded but instead repurposed, reducing waste and creating additional revenue streams for production facilities.

LANE’s eco-friendly byproduct management systems not only reduce the environmental impact of Superphosphate SSP Compound Production but also help manufacturers meet regulatory requirements concerning waste disposal. This focus on sustainability ensures that the production process supports long-term environmental goals while remaining economically viable.

Conclusion: A New Era for Superphosphate SSP Compound Production

The innovations introduced by LANE in Superphosphate SSP Compound Production are driving significant improvements in the fertilizer industry. With energy-efficient reaction systems, advanced granulation techniques, automated quality control, and eco-friendly byproduct management, LANE is at the forefront of a new era in sustainable fertilizer production. These technological advancements not only lower costs and boost product quality but also align with global efforts to make agriculture more environmentally responsible.

As the demand for high-quality fertilizers continues to rise, innovations like these are essential to ensure that the industry can meet the needs of modern agriculture while minimizing its environmental footprint. LANE’s Superphosphate SSP Compound Production lines are setting new standards, providing farmers with the tools they need to enhance crop yields, improve soil health, and secure a sustainable future for agriculture.

Send a message to us