Global Potassium Sulfate Demand Growth: The Importance of Sulphate of Potash Production Line Equipment Selection

As the global population continues to rise, the demand for high-quality agricultural products is increasing rapidly. Potassium sulfate (K₂SO₄), commonly known as Sulphate of Potash (SOP), is one of the most important fertilizers used to enhance crop yield and quality, particularly in crops sensitive to chloride, such as tobacco, fruits, vegetables, and nuts. Unlike its counterpart, Muriate of Potash (MOP), SOP offers a chloride-free source of potassium and also provides essential sulfur, making it a more desirable option in certain agricultural sectors. With the global market for SOP expected to grow significantly in the coming years, the importance of selecting the right production line equipment for SOP manufacturing becomes crucial.

This article will explore the key factors driving the global growth in potassium sulfate demand and emphasize the importance of proper Sulphate of Potash Production Line Equipment selection to meet the rising demand efficiently.

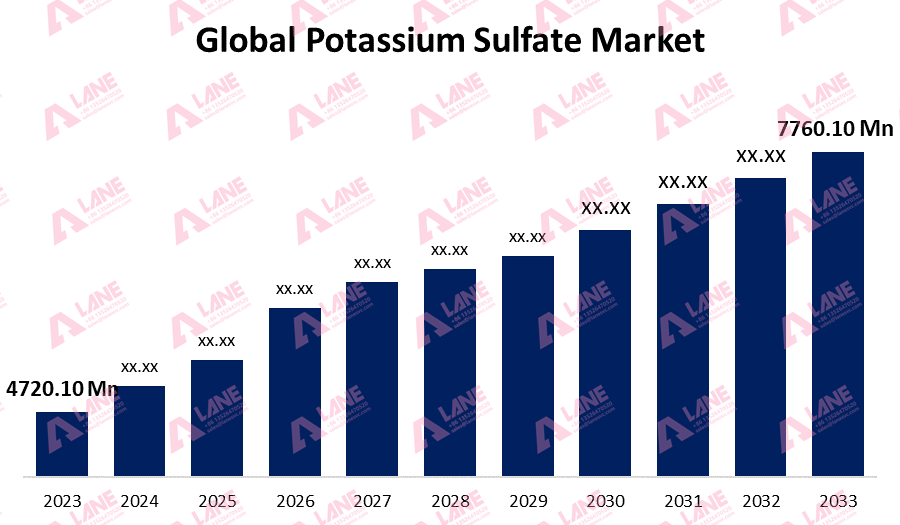

Rising Global Demand for Potassium Sulfate

The global SOP market is experiencing steady growth, driven by several factors. These factors include the increasing need for sustainable agriculture, a rise in global food demand, and heightened awareness of the importance of high-quality fertilizer for sensitive crops. Let’s take a closer look at these drivers.

Sustainable Agriculture and Soil Health

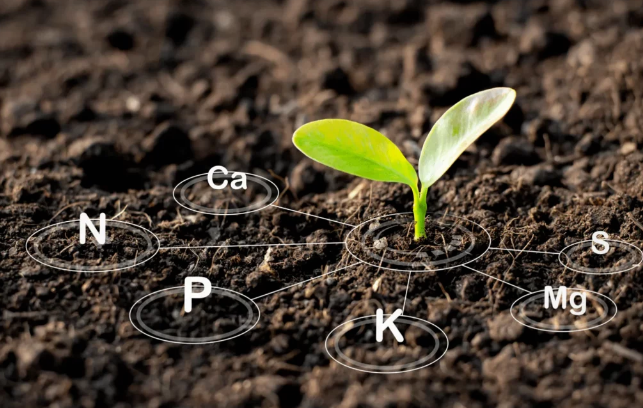

One of the primary reasons for the increasing demand for SOP is the growing focus on sustainable farming practices. Farmers and agricultural producers are more aware of the long-term impact of fertilizers on soil health and crop productivity. SOP, being chloride-free, is particularly advantageous because it prevents the buildup of harmful salts in the soil, which can lead to soil degradation and decreased fertility over time. This aspect of SOP is particularly important in regions that already experience high soil salinity, where using MOP would exacerbate the problem.

Additionally, SOP contains sulfur, an essential secondary nutrient that promotes protein synthesis and enzyme activation in plants. With increased soil sulfur deficiencies worldwide, the dual nutrient benefits of SOP make it a highly attractive fertilizer, boosting its demand across various agricultural regions.

Increasing Food Demand

With the global population projected to exceed 9 billion by 2050, there is an urgent need to increase agricultural productivity. The world’s agricultural output must grow significantly to meet the rising demand for food, especially in developing countries. SOP, as a high-performance fertilizer, plays a crucial role in meeting these productivity goals. Its ability to enhance crop yield while preserving soil health makes it an essential component of modern agriculture. Moreover, SOP’s chloride-free composition is particularly important for growing crops such as fruits, vegetables, and coffee, where high chloride levels can negatively impact crop taste and quality.

Climate-Resilient Crops

The increasing unpredictability of weather patterns due to climate change is putting pressure on farmers to adapt their agricultural practices. SOP’s dual nutrient benefit of potassium and sulfur helps strengthen plant roots, enhance drought tolerance, and increase resistance to diseases. These properties make SOP highly effective in helping farmers mitigate the impact of erratic weather patterns and climate-induced stresses on their crops. Consequently, as farmers strive to protect their crops from environmental uncertainties, the demand for SOP is expected to continue growing.

The Role of Sulphate of Potash Production Line Equipment Selection

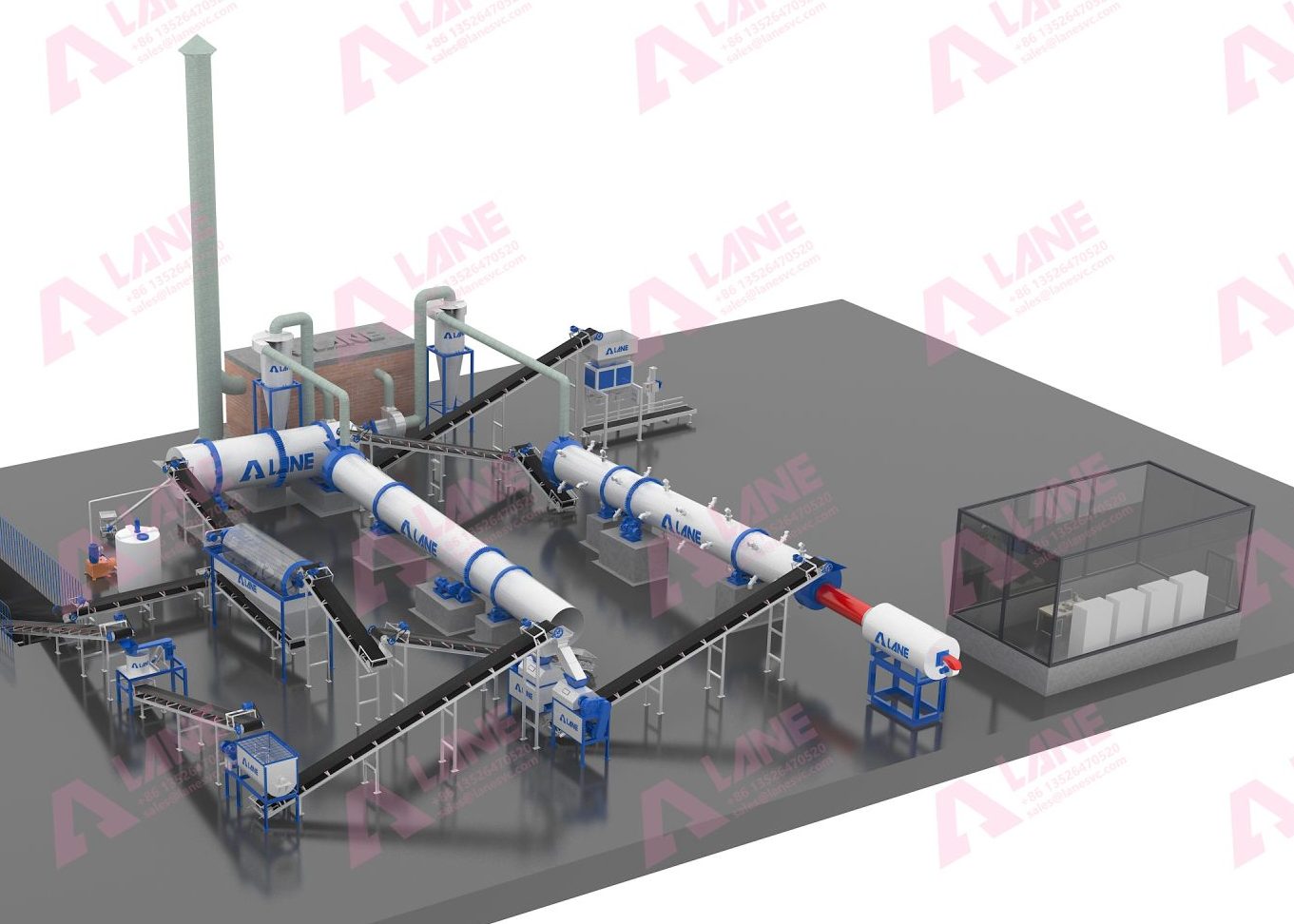

As global potassium sulfate demand increases, the ability to manufacture SOP at a large scale and high quality is more critical than ever. For fertilizer manufacturers, the choice of SOP production line equipment is essential to meet market demands efficiently, ensure product quality, and maintain cost-effectiveness. Proper selection of production line equipment can have a profound impact on the overall productivity and profitability of an SOP manufacturing facility. Here are some critical aspects of equipment selection:

Granulation Equipment for Uniform Product Quality

Granulation is a crucial step in Sulphate of Potash Production Line Equipment, as it determines the size, shape, and uniformity of the final product. Uniform granules are easier to apply in the field, ensuring even distribution of nutrients and reducing waste. Therefore, manufacturers must carefully choose between different granulation technologies, such as disc granulators and rotary drum granulators, based on their production needs.

- Disc Granulators: These machines offer excellent control over the size of the granules and are ideal for producing small, uniform particles. They are particularly useful for producing SOP fertilizers that are applied in precision farming, where accurate nutrient delivery is critical.

- Rotary Drum Granulators: For larger-scale production, rotary drum granulators offer the advantage of producing durable, high-strength granules that are easy to transport and store. These granulators can handle higher production volumes, making them suitable for manufacturers aiming to meet global SOP demand.

Drying and Cooling Systems for Product Stability

After granulation, SOP granules must be properly dried and cooled to ensure their long-term stability during storage and transportation. SOP fertilizers with high moisture content are prone to caking, which can affect their flowability and handling. Therefore, efficient drying systems are essential to achieve the desired moisture content in the final product.

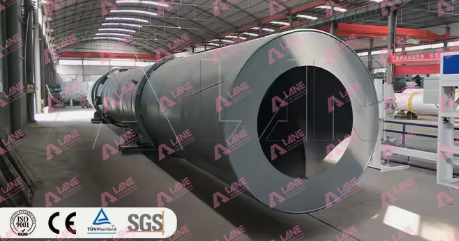

- Rotary Drum Dryers: These are widely used in Sulphate of Potash Production Line Equipment for their ability to remove moisture evenly and efficiently from the granules. They use a combination of indirect heating and airflow control to achieve consistent drying without compromising the integrity of the granules.

- Rotary Coolers: After drying, the granules are cooled to a stable temperature that ensures they remain free-flowing during storage. Cooling is also essential to avoid temperature-related degradation that could reduce the fertilizer’s effectiveness.

Dust and Waste Recovery Systems for Sustainability

The Sulphate of Potash Production Line Equipment generates fine dust and by-products, especially during the granulation and drying stages. To minimize environmental impact and reduce waste, the inclusion of dust collection systems is vital. These systems capture dust particles and prevent them from being released into the environment, ensuring that the production facility remains compliant with environmental regulations.

- Cyclone Dust Collectors: These are highly effective at separating dust from the Sulphate of Potash Production Line Equipment, capturing the fine particles generated during granulation and drying. The collected dust can then be reintegrated into the production process, improving overall material utilization and reducing waste.

Energy Efficiency and Sustainability

The energy demands of Sulphate of Potash Production Line Equipment are substantial, making energy efficiency a key consideration in selecting Sulphate of Potash Production Line Equipment. Choosing equipment that incorporates energy-saving features—such as heat recovery systems in dryers—can significantly reduce operational costs while minimizing the environmental footprint of the production process.

- Heat Recovery Systems: In rotary dryers, the heat generated during the drying process can be captured and reused in other parts of the production line. This reduces the overall energy consumption of the facility and contributes to more sustainable fertilizer production.

Conclusion

As the global demand for potassium sulfate continues to rise, manufacturers face increasing pressure to produce high-quality SOP fertilizers efficiently and sustainably. The selection of the right Sulphate of Potash Production Line Equipment is critical in achieving these goals. From granulation and drying systems to dust collection and energy recovery, each piece of equipment plays a pivotal role in ensuring that the production process meets both quality and quantity demands.

By investing in advanced production technologies, fertilizer manufacturers can not only keep up with the growing market demand but also contribute to more sustainable agricultural practices worldwide. As the agricultural sector continues to evolve, the importance of SOP fertilizer and the Sulphate of Potash Production Line Equipment used to produce it will only continue to grow, ensuring that farmers have the tools they need to feed a rapidly expanding global population.

About LANE

Henan LANE Heavy Industry Machinery Technology Co, Ltd. is a fertilizer industry leader certified by Alibaba and a machine supplier for Africa’s 100000 ton annual national fertilizer project. We have professional experience in manufacturing fertilizer production equipment,which can help customers effectively solve the production problems of organic fertilizer, compound fertilizer, bio-mas fertilizer,mineral fertilizer and BB fertilize.

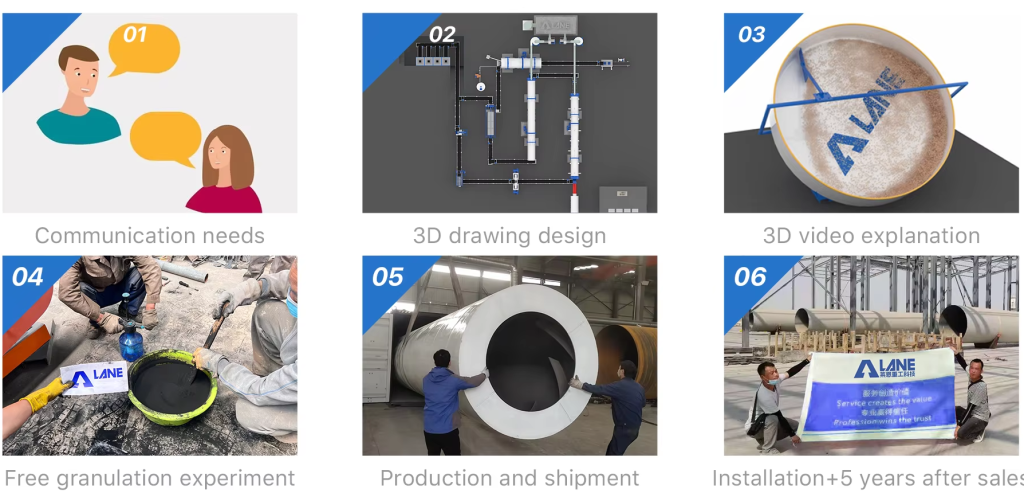

Our Service

Send a message to us