Sulphate of Potash Production Line

The Sulphate of Potash (SOP) Production Line is a highly efficient and technologically advanced system designed to produce high-quality SOP fertilizer. Known for its high potassium content and low chloride levels, SOP is essential for chloride-sensitive crops such as fruits, vegetables, and tobacco. This production line ensures a consistent and reliable output, meeting the growing demands of the agricultural industry.

What We Offer:

- Production process design

- Professional technical guidance

- Equipment Customization & Manufacturing

- Overseas engineers on-site installation

- 5 Years Warranty

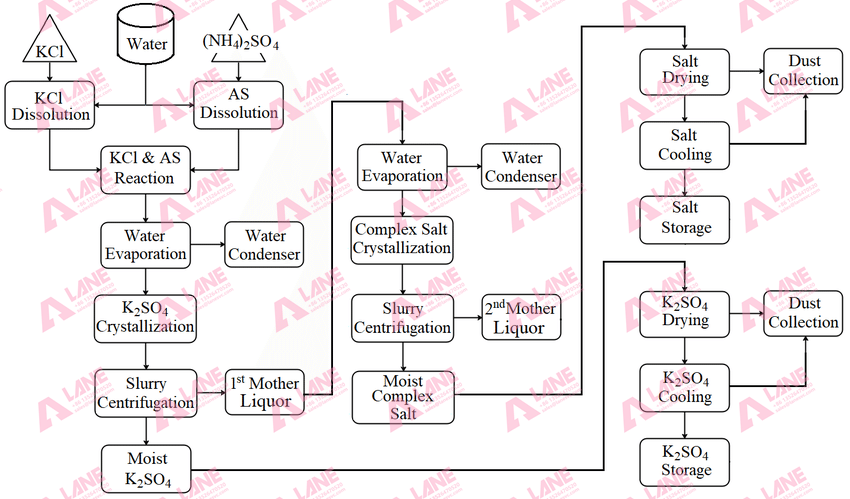

Overview of Production Process

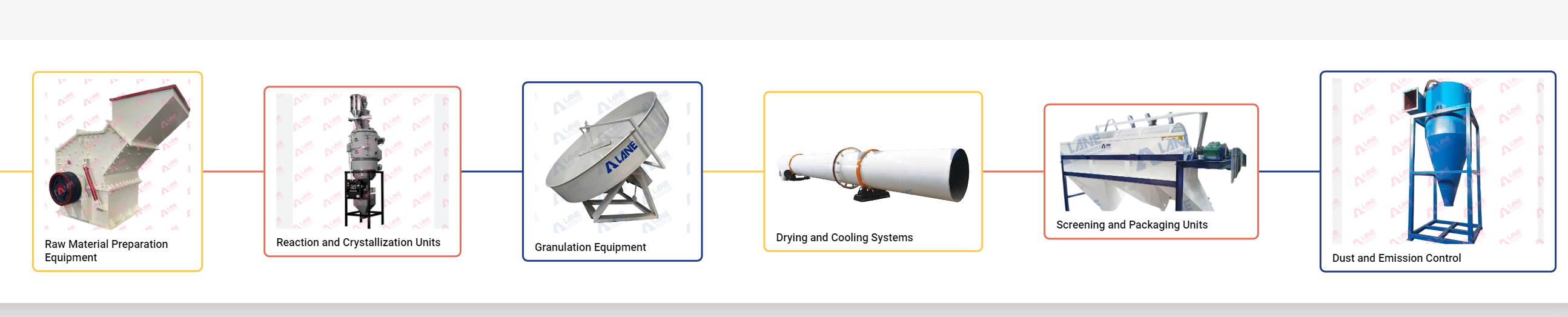

Key Equipment in the Production Process

- Raw Material Preparation Equipment

Crushers: Used to grind raw materials like potassium chloride into fine particles.

Mixers: Ensure a uniform mixture of raw materials before the chemical reaction.

- Reaction and Crystallization Units

Reactors: Where the chemical reaction between potassium chloride and sulfuric acid occurs to produce potassium sulfate.

Crystallizers: Facilitate the formation of potassium sulfate crystals from the reaction mixture.

- Granulation Equipment

Rotary Drum Granulator: Granulates the crystallized potassium sulfate into uniform-sized granules suitable for agricultural use.

Disc Granulator: An alternative granulation method that offers flexibility in adjusting granule size.

- Drying and Cooling Systems

Rotary Dryer: Removes excess moisture from the granules, enhancing their storage and transport stability.

Rotary Cooler: Cools the dried granules to the desired temperature, preventing clumping during packaging.

- Screening and Packaging Units

Rotary Screen Machine: Screens the granules to separate fine particles and oversized granules, ensuring uniformity in the final product.

Automatic Packing Machine: Packages the screened granules into bags for distribution, ensuring accuracy and efficiency.

- Dust and Emission Control

Cyclone Dust Collectors: Capture dust generated during the crushing, drying, and granulation processes, maintaining a clean production environment.

Scrubbers: Remove harmful gases and particulates from the exhaust, ensuring compliance with environmental regulations.

Key Features of the Sulphate of Potash Production Line

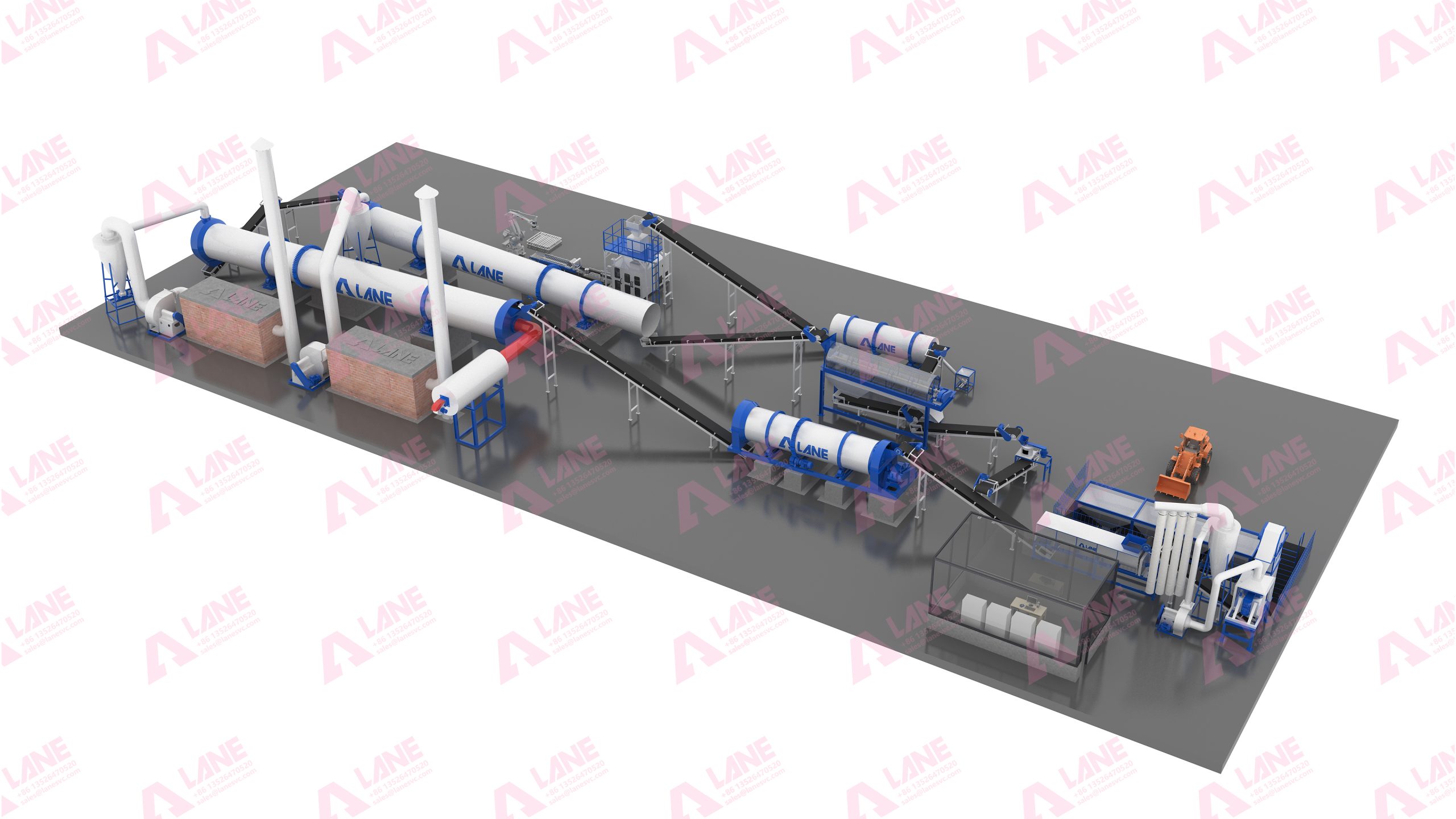

Optimized Production Process:The SOP production line is engineered to maximize efficiency, ensuring high output with minimal waste. This optimization results in a more cost-effective production process, allowing manufacturers to produce large quantities of SOP at a lower cost.

Advanced Technology Integration:Cutting-edge technology is integrated throughout the production line, from raw material processing to final product packaging. Automated systems enhance precision and reduce human error, leading to a more consistent and reliable product.

Customizable Output:The production line can be tailored to produce SOP in various forms, such as granules, powder, or crystals, depending on market requirements. This flexibility allows manufacturers to meet the specific needs of different agricultural sectors.

Environmental Sustainability:The production line is designed with environmental considerations in mind. Efficient waste management and emission control systems are implemented to minimize the environmental impact, making the production process more sustainable.

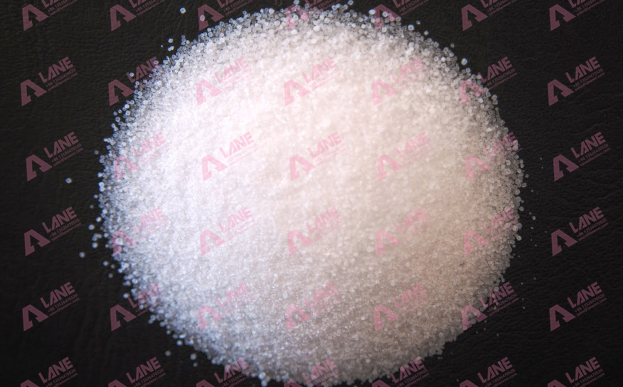

Product Display

About Us

Real-Life Shipping Cases of Our Products

One Stop Service

Certificate

Want to know more?