Sulfuric Acid Storage Tank

Sulfuric acid is a vital component in the production of fertilizers, chemicals, and various industrial processes. However, its storage poses significant challenges due to its corrosive nature, which can cause severe damage to standard materials and equipment. Improper storage of sulfuric acid can lead to leaks, spills, and even catastrophic failures, posing serious risks to personnel, the environment, and production processes.

To mitigate these risks, it is essential to use storage tanks specifically designed for sulfuric acid. These tanks must be constructed from materials that can withstand the corrosive effects of sulfuric acid, while also providing sufficient strength and durability to ensure long-term, safe storage.

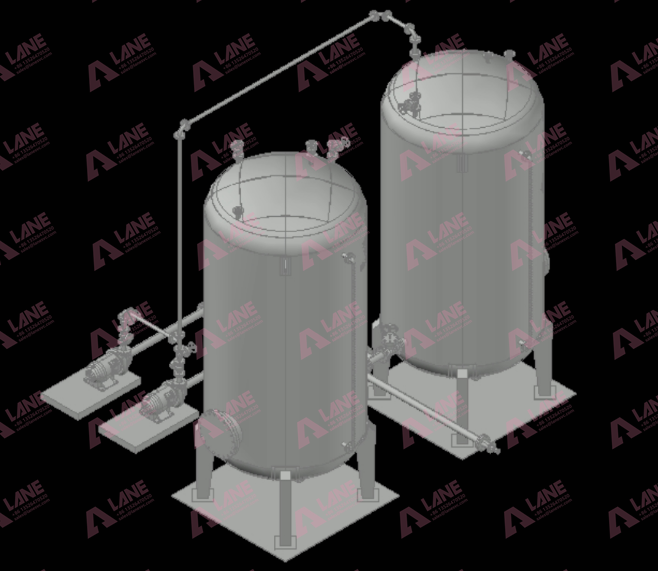

Sulfuric acid is one of the most widely used chemicals in various industries, including manufacturing, mining, and agriculture. Due to its highly corrosive nature, the storage of sulfuric acid requires specialized equipment designed to handle its aggressive properties safely. LANE Group offers advanced Sulfuric Acid Storage Tanks that provide robust and reliable storage solutions, ensuring both safety and efficiency in industrial operations.

Sulfuric acid is a key ingredient in the production of phosphate fertilizers. LANE Group’s tanks provide secure storage for sulfuric acid, ensuring that it is readily available for use in fertilizer manufacturing processes.

Key Features of LANE Sulfuric Acid Storage Tanks

LANE Sulfuric Acid Storage Tanks are engineered to meet the highest standards of safety and performance. Here are some of the key features that make these tanks ideal for storing sulfuric acid:

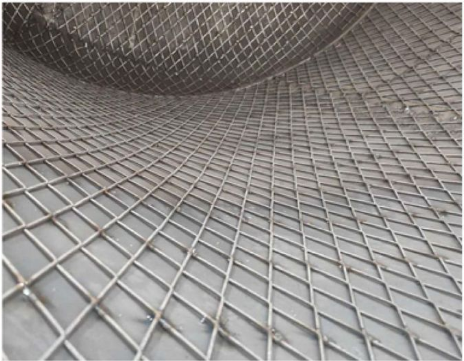

- Corrosion-Resistant Materials: The tanks are constructed from materials specifically chosen for their resistance to sulfuric acid corrosion. Common materials include high-density polyethylene (HDPE), fiberglass-reinforced plastic (FRP), and stainless steel, depending on the concentration and temperature of the acid being stored.

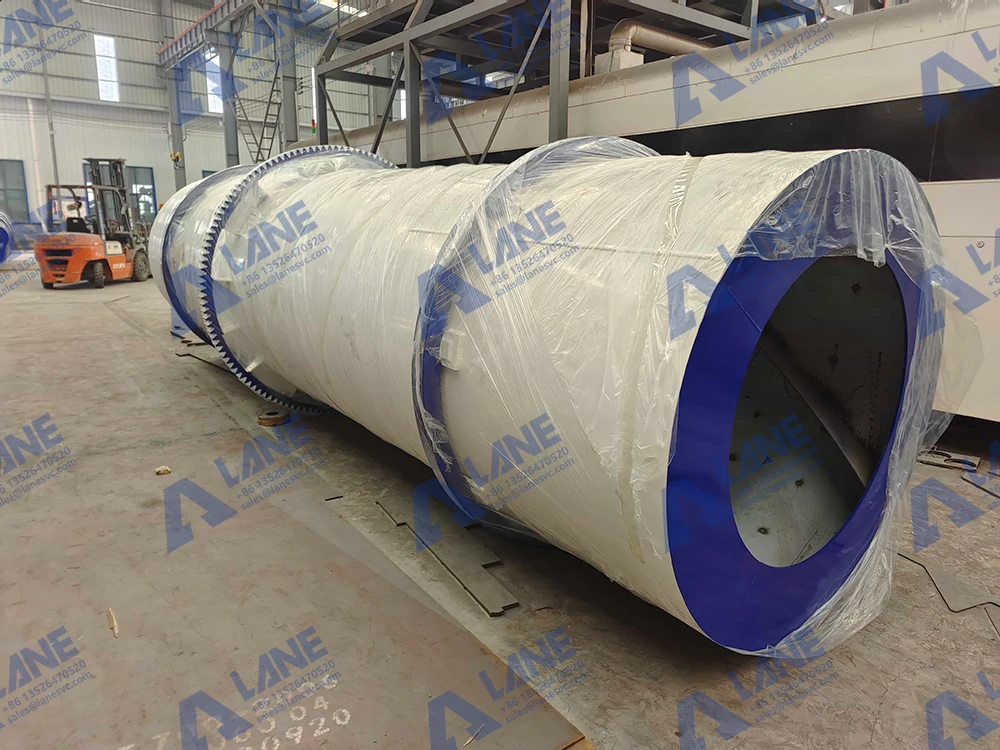

- Robust Design: LANE Group’s tanks are designed with reinforced walls and secure fittings to withstand the pressure and weight of sulfuric acid. The design also includes features to prevent leakage and ensure that the tank remains structurally sound over time.

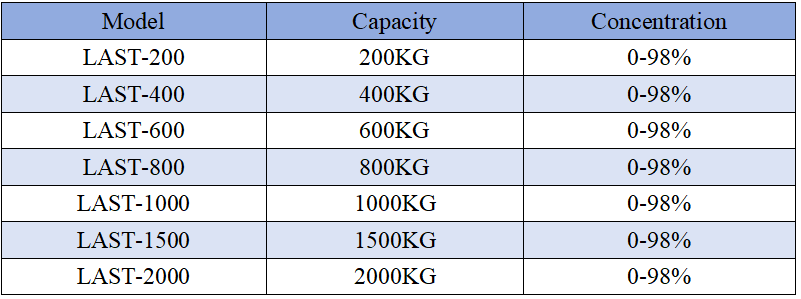

- Customizable Options: LANE Group offers a range of customizable options, including tank size, shape, and material, to meet the specific needs of different industrial applications. Whether you need a small tank for limited storage or a large-capacity tank for bulk storage, LANE Group can provide a solution that fits your requirements.

- Safety Features: The tanks are equipped with safety features such as venting systems, overfill protection, and leak detection to minimize the risk of accidents. These features are essential for maintaining a safe working environment and preventing environmental contamination.

- Temperature Control: For applications where sulfuric acid is stored at elevated temperatures, LANE Group’s tanks can be equipped with temperature control systems to maintain the acid at the desired temperature, preventing crystallization and ensuring proper flow during processing.

Advantages

When you choose LANE Group’s Sulfuric Acid Storage Tanks, you benefit from a range of advantages that enhance the safety and efficiency of your operations:

- Durability: The tanks are built to last, with materials and construction methods that ensure long-term resistance to corrosion and other forms of wear and tear.

- Safety: LANE Group prioritizes safety in the design and manufacture of its storage tanks, providing features that reduce the risk of leaks, spills, and other hazards associated with sulfuric acid storage.

- Customization: LANE Group offers tailored solutions to meet the specific requirements of your operation, ensuring that your storage tanks are perfectly suited to your needs.

- Expert Support: LANE Group provides comprehensive support, including installation, maintenance, and technical assistance, to ensure that your sulfuric acid storage system operates smoothly and efficiently.

Best Practices for Sulfuric Acid Storage

To maximize the safety and longevity of your sulfuric acid storage system, it is important to follow best practices for storage and handling:

- Regular Inspections: Conduct regular inspections of your storage tanks and associated equipment to identify any signs of corrosion, leaks, or structural damage. Early detection of potential issues can prevent costly repairs and reduce the risk of accidents.

- Proper Ventilation: Ensure that your storage tanks are equipped with proper ventilation systems to prevent the buildup of pressure and gases. Adequate ventilation is crucial for maintaining the safety of the storage environment.

- Temperature Monitoring: Monitor the temperature of the stored sulfuric acid to prevent crystallization or other issues that could affect the flow and handling of the acid. Temperature control systems can help maintain the acid at the optimal temperature.

- Training and Procedures: Provide comprehensive training to personnel on the safe handling and storage of sulfuric acid. Establish clear procedures for filling, transferring, and maintaining the storage tanks to minimize the risk of accidents.

Application Scenarios

- Fertilizer Production Line

- Chemical Manufacturing

- Mining Industry

If you want to know more, Contact us!

Latest Articles & Tips

More-

01/20

read more -

09/11

read more6 Strategies to Maximize Output with a Triple Superphosphate Fertilizer Production Line

-

09/26

The Hidden Benefits of SSP Fertilizer Plants You Didn’t Know About

read more -

09/29

read moreUnlocking Nutrient Potential: The Single Calcium Phosphate Fertilizer Production Explained