Sulfur-Coated Urea Production Unit: Practical Guide to Controlled-Release Fertilizer Manufacturing

Sulfur-Coated Urea Production Unit Overview

A sulfur-coated urea production unit is designed to manufacture controlled-release nitrogen fertilizer by coating standard urea granules with a sulfur layer. This coating slows nitrogen release after application, improving nutrient efficiency and reducing losses caused by volatilization and leaching.

In fertilizer manufacturing, sulfur-coated urea is considered a practical solution rather than a laboratory product. Its success depends on stable operation, coating consistency, and equipment reliability. For producers, the focus is not only on output capacity but also on long-term performance during storage and transportation.

What Is a Sulfur-Coated Urea Production Unit?

In simple terms, a sulfur-coated urea production unit applies molten sulfur onto moving urea granules to form a protective shell. This shell controls how fast nitrogen dissolves in soil moisture.

Unlike polymer-coated fertilizers, sulfur-coated urea relies on physical coating thickness and surface integrity. Once applied in the field, cracks in the sulfur layer gradually allow nitrogen release. This makes production quality control especially important.

Most sulfur-coated urea production units are installed as standalone systems or integrated into existing fertilizer plants. This flexibility allows manufacturers to upgrade product lines without major changes to upstream processes.

Why Sulfur-Coated Urea Is Used in Fertilizer Manufacturing

Sulfur-coated urea offers both agronomic and industrial advantages. From a production standpoint, it balances performance improvement with relatively moderate investment.

Key reasons manufacturers adopt this technology include:

Improved nitrogen use efficiency

Reduced environmental nitrogen losses

Longer nutrient availability period

Added sulfur nutrition for crops

Higher product differentiation in the market

For producers targeting specialty fertilizer segments, sulfur-coated urea provides a clear upgrade from conventional urea products.

Sulfur-Coated Urea Production Process Explained

- Urea Granule Preparation

Production begins with standard urea granules. Granule size uniformity is essential. Irregular particles often lead to uneven coating thickness, which affects nutrient release behavior.

In practice, screening and conditioning are used to remove fines and oversized particles before coating.

- Heating and Surface Conditioning

Before sulfur application, urea granules are gently heated. This step improves sulfur adhesion. Temperature must be carefully controlled. Excess heat can deform granules, while low temperature reduces coating quality.

This stage is often underestimated but plays a key role in coating stability.

- Sulfur Melting and Application

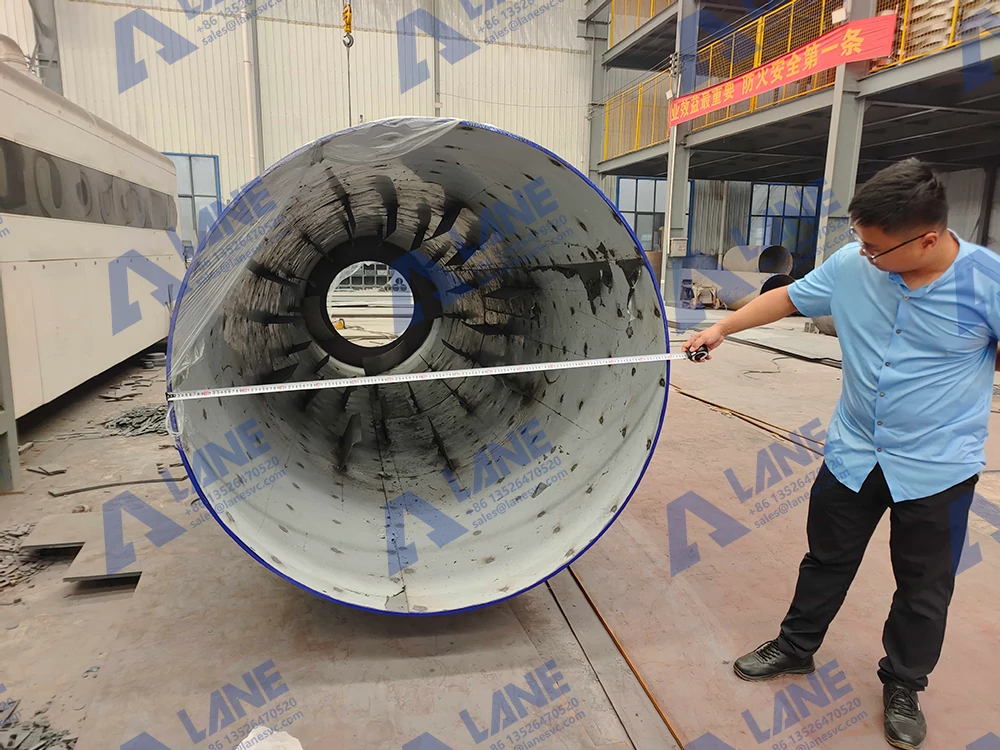

Solid sulfur is melted and maintained at a stable temperature. Molten sulfur is sprayed onto rotating urea granules inside a coating drum.

Uniform spraying and drum rotation are critical. Fluctuations in sulfur flow or drum speed often cause coating defects such as bare spots or excessive thickness.

- Cooling and Solidification

After coating, granules pass through a cooling stage. Cooling allows the sulfur layer to solidify and form a stable shell.

Insufficient cooling may cause surface cracking during handling. Proper cooling improves storage stability and reduces caking risk.

- Screening and Quality Control

Finished products are screened to remove broken or poorly coated granules. Quality control focuses on coating integrity rather than appearance alone.

In industrial production, consistent release behavior is a more important indicator than visual uniformity.

Main Equipment in a Sulfur-Coated Urea Production Unit

A complete sulfur-coated urea production unit typically includes:

Urea feeding and conveying system

Sulfur melting tank

Coating drum

Dust collection system

Equipment selection should be based on raw material characteristics and production scale rather than theoretical capacity alone.

Key Factors Affecting Product Quality

Several operational factors directly influence the final product:

Urea granule size distribution

Sulfur purity and temperature stability

Coating thickness control

Drum rotation stability

Cooling efficiency

Plants that maintain stable operating conditions usually experience fewer quality issues and lower reprocessing rates.

Integration with Compound Fertilizer Plants

A sulfur-coated urea production unit can be integrated into compound fertilizer or NPK plants. In this configuration, sulfur-coated urea serves as a controlled-release nitrogen source.

This integration allows manufacturers to produce both conventional and specialty fertilizers within one facility. It also improves raw material utilization and production flexibility.

From an operational view, integration requires careful layout planning to ensure smooth material flow.

For internationally recognized fertilizer classification and quality standards, refer to the fertilizer specifications provided by the Food and Agriculture Organization (FAO). The FAO guidance outlines global specifications and classifications for various fertilizers, including straight nutrient products such as urea and coated products, which helps manufacturers align production and quality control with international norms.

Operational Challenges and Maintenance Considerations

Like any coating system, sulfur-coated urea production units require regular inspection and maintenance. Common challenges include sulfur solidification in pipelines, nozzle blockage, and coating drum wear.

Routine cleaning, temperature monitoring, and spare part management help minimize downtime. Preventive maintenance is often more cost-effective than reactive repairs.

Choosing the Right Sulfur-Coated Urea Production Unit Supplier

Selecting a suitable supplier is as important as choosing the equipment itself. Manufacturers should evaluate practical project experience rather than promotional claims.

A reliable supplier should offer:

Process design based on actual raw materials

Equipment matched to operating conditions

Installation and commissioning support

Operator training and long-term service

These factors often determine whether a production unit performs reliably after startup.

Conclusion

A sulfur-coated urea production unit is a proven solution for producing controlled-release nitrogen fertilizer. When properly designed and operated, it improves nutrient efficiency and expands product offerings. Long-term success depends on coating quality, process stability, and appropriate equipment selection rather than nominal output figures.

Call to Action

If you are planning a sulfur-coated urea production unit or upgrading an existing fertilizer plant, early technical evaluation can reduce risks and operating costs. Professional process support helps ensure stable operation and consistent product quality from startup to long-term production.

Ready to choose the right fertilizer solution? Contact LANE today to learn more about .

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Send a message to us