Stirring Pin Granulator: 95%+ Pelletizing Rate, 1-10 T/H for Organic Fertilizer

The production of high-quality organic fertilizer demands equipment that delivers both exceptional yield and consistent pellet quality. The Stirring Pin Granulator meets this challenge head-on, engineered to achieve a pelletizing rate exceeding 95% within a versatile capacity range of 1 to 10 tons per hour. This technology transforms organic powders into uniform, dense, and spherical pellets through a highly efficient mechanical agitation process, making it the cornerstone of modern, profitable organic fertilizer production lines.The technology supports the global aim of enhancing sustainable fertilizer use and management. Henan Lane Heavy Industry integrates this proven granulation method into robust, reliable systems for global clients.

What is a Stirring Pin Granulator?

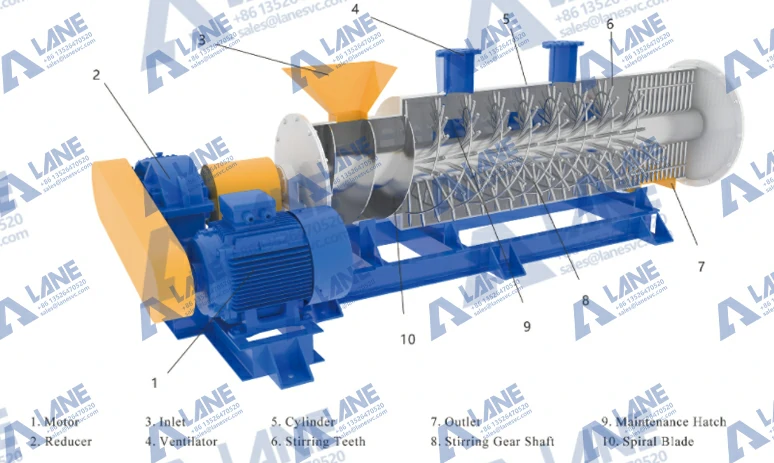

A Stirring Pin Granulator is a type of wet granulation equipment characterized by a horizontal cylindrical drum. Inside, a central rotor shaft equipped with numerous radial pins rotates at high speed. The process involves introducing fine powder and a liquid binder into the drum. The high-speed rotation creates a violent, turbulent vortex, forcing particles to collide, coalesce, and form dense, spherical pellets through a layering mechanism. It is renowned for producing uniform, round pellets with high strength, ideal for organic fertilizer granulation and premium product lines.

How Does It Work? The Granulation Process Explained.

The efficiency of the Stirring Pin Granulator lies in its dynamic, mechanical agitation process:

Mixing and Nucleation: Dry raw materials (e.g., composted organic matter) are fed into the drum alongside a sprayed liquid binder. The high-speed rotating pins instantly create a turbulent mixing zone, forming thousands of small, moist nuclei.

Growth and Spheronization: Nuclei are violently tossed and tumbled, constantly colliding. This action compacts them and allows more fine powder to adhere, causing pellets to grow and become spherical.

Polishing and Discharge: Continued tumbling “polishes” the pellets, smoothing the surface and increasing strength before discharge for subsequent drying in a complete fertilizer production line.

Key Advantages of the Stirring Pin Granulator Technology

Superior Pellet Uniformity and Shape: Produces exceptionally round and uniform spherical pellets with a smooth surface, which are highly preferred in the premium fertilizer market.

High Granulation Rate & Efficiency: Achieves a pellet formation ratio exceeding 95% with minimal recycle of fine material, optimizing raw material use and production throughput.

Gentle yet Effective: The process is ideal for organic fertilizers and bio-fertilizers containing living microorganisms, as it avoids excessive shear or heat that could degrade sensitive components.

Strong and Dense Pellets: The intense mechanical action produces hard, abrasion-resistant pellets that withstand packaging, storage, and transportation.

- Flexibility and Adjustability: Pellet size can be controlled by adjusting process parameters such as rotor speed and binder ratio, offering flexibility for different product specifications.

Primary Applications in Organic and Specialty Fertilizer Production

The Stirring Pin Granulator is the equipment of choice for:

Organic Fertilizer Granulation: Transforming compost, manure, and other organic matter into commercial-grade granular fertilizer.

Bio-fertilizer Production: Granulating carrier materials impregnated with beneficial bacteria or fungi without damaging microbial life.

Premium Compound Fertilizers: Producing high-value, uniformly blended NPK or specialty fertilizer pellets.

Cat Litter Production: Forming highly absorbent and clumping granules from materials like bentonite.

Henan Lane‘s Expertise in Granulation Solutions

Henan Lane Heavy Industry designs and manufactures Stirring Pin Granulators that combine robust construction with process efficiency. Our machines are engineered for continuous, trouble-free operation in demanding production environments. We support our equipment with comprehensive organic fertilizer production line design and professional technical guidance, ensuring our clients achieve optimal results.

Why Choose Henan Lane for Your Granulation Project?

Proven Technology & Customization: Our granulators are built based on extensive experience. We offer solutions from 1 to 10 T/H and can customize aspects to fit your specific production line needs.

Free Granulation Testing: We offer no-obligation granulation tests in our lab using your raw materials to determine optimal parameters and guarantee results before purchase.

Global Support Network: With a presence in over 120 countries, we provide timely after-sales service and operational support, backed by a professional overseas after-sales team.

Take the Next Step Toward Premium Pellet Production

If your goal is to produce superior-quality, uniform organic fertilizer pellets with high efficiency and reliability, the Stirring Pin Granulator technology offers the ideal solution.

Contact Henan Lane Heavy Industry today to discuss your requirements, request a free material granulation test report, or receive a detailed quotation for a system tailored to your production goals.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Send a message to us