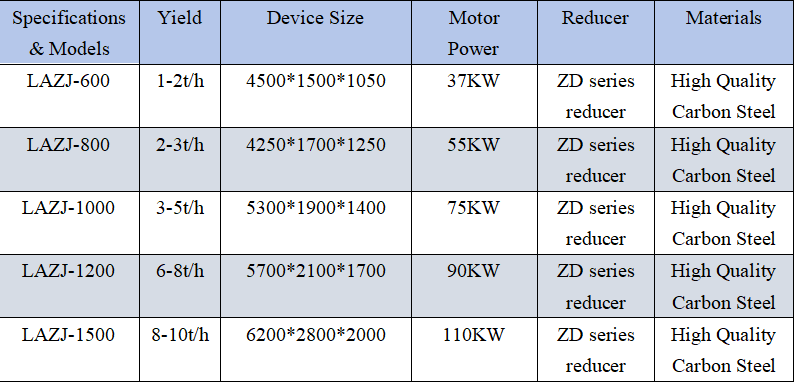

Stirring Pin Granulator

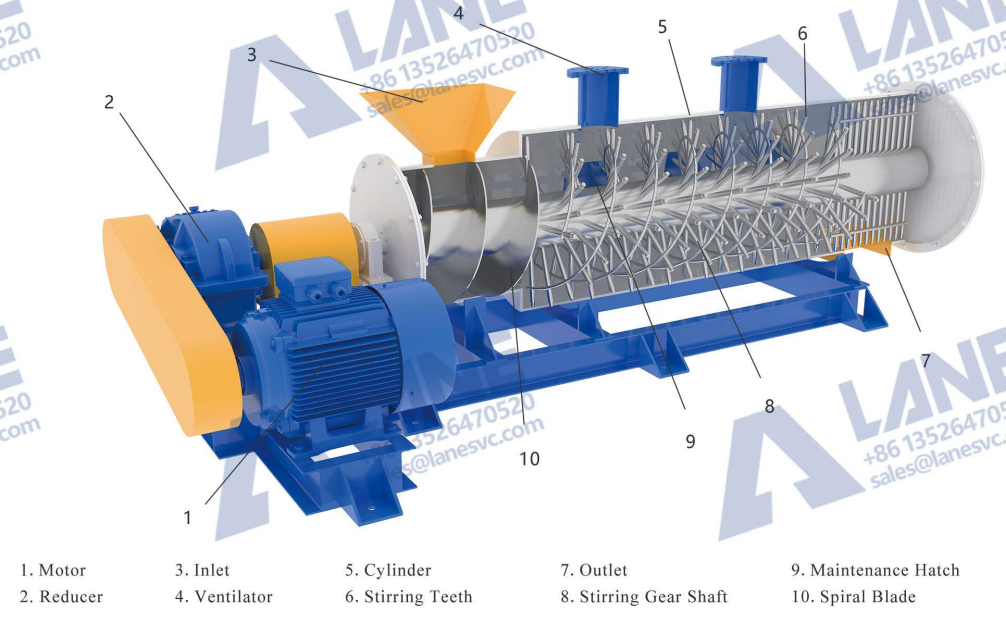

A Stirring Pin Granulator, also known as a Pin Mill Granulator, is a type of granulation equipment that uses a combination of mechanical stirring and pin action to convert powdered raw materials into uniform granules. The granulator consists of a rotating shaft fitted with multiple stirring pins that agitate the material. As the materials are agitated, they collide with each other and with the walls of the granulator, leading to the formation of granules.

This granulation method is particularly effective for organic materials, ensuring that the nutrients are preserved while achieving the desired granule size. The stirring pin granulator is highly versatile and can be used for a wide range of organic and bio-fertilizers, making it an essential tool for modern fertilizer production.

Granulation Process of Stirring Pin Granulator

LANE Group’s Stirring Pin Granulator is engineered to optimize the granulation process, ensuring high efficiency and consistent product quality:

Raw Material Preparation: The process begins with the selection and preparation of raw materials, typically including powdered organic matter, bio-fertilizers, and other essential nutrients. These materials are fed into the granulator in a controlled manner to ensure uniformity.

Stirring and Granulation: As the material enters the granulator, the rotating shaft with stirring pins begins to agitate the material. The intense stirring action causes the particles to collide and stick together, forming granules. The granulation process is further enhanced by the use of binders or liquid additives, which help to improve the binding of particles.

Granule Formation: The granules are formed as the material continues to be agitated by the stirring pins. The size and shape of the granules can be controlled by adjusting the speed of the rotating shaft, the number of stirring pins, and the amount of binder used.

Structure of Stirring Pin Granulator

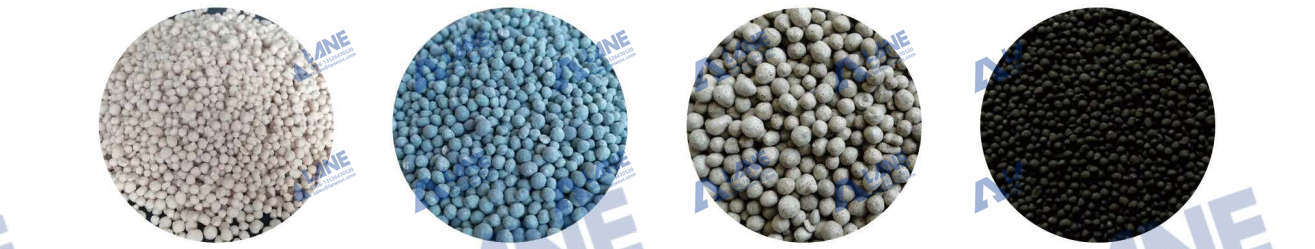

Finsihed Product Display

Applications of the Stirring Pin Granulator

The Stirring Pin Granulator is widely used in the production of various types of fertilizers, making it a versatile tool in the agricultural industry:

- Organic Fertilizers: The granulator is ideal for producing organic fertilizers from composted materials, manure, and other organic matter, converting them into high-quality granules.

- Bio-Fertilizers: The gentle granulation process is perfect for bio-fertilizers, which contain living microorganisms that enhance soil fertility and plant growth.

- Compound Fertilizers: The granulator can also be used to produce compound fertilizers that combine organic and inorganic materials, offering comprehensive nutrition for crops.

Advantages of Stirring Pin Granulator

LANE Group’s Stirring Pin Granulator offers several key advantages that make it an excellent choice for fertilizer production:

- High Granulation Efficiency: The stirring action of the pins ensures that the material is thoroughly mixed and granulated, resulting in a high percentage of uniform granules.

- Uniform Granule Size: The granulator produces granules that are uniform in size and shape, which is essential for even nutrient distribution in agricultural applications.

- Versatility: The stirring pin granulator can process a wide range of organic and bio-fertilizers, making it suitable for various fertilizer production needs.

- Preservation of Nutrients: The gentle granulation process ensures that the nutrients in the organic material are preserved, making the final product highly effective as a fertilizer.

- Energy Efficiency: The granulator is designed to operate efficiently, reducing energy consumption and operational costs.

Our Clients & Cases