SSP Fertilizer Production Line: Process, Equipment, and Plant Design

Single Superphosphate (SSP) fertilizer remains one of the most widely used phosphate fertilizers in global agriculture, notable for its balanced delivery of phosphorus (P₂O₅), sulfur (S), and calcium (Ca) to crops. Unlike more concentrated fertilizers, SSP is prized for its cost efficiency, simple production technology, and adaptability across diverse soil conditions. An SSP fertilizer production line is a specialized industrial system designed to convert phosphate rock into stable, agriculturally effective fertilizer at scale, with high operational efficiency and low environmental impact.

What Is SSP Fertilizer and Why It Matters

Single Superphosphate fertilizer is manufactured through the chemical reaction of phosphate rock with sulfuric acid, producing water-soluble monocalcium phosphate along with calcium sulfate (gypsum). Compared with more concentrated phosphate fertilizers, SSP typically contains 16–22% P₂O₅, along with secondary nutrients beneficial for crop growth.

According to the United Nations Environment Programme’s fertilizer production guidelines, SSP production involves converting mineral phosphate into a form usable by plants while retaining gypsum as a soil amendment, and it continues to be an essential component of phosphate fertilizer portfolios where sulfur availability is critical or cost sensitivity is high.

SSP’s role in agriculture is enhanced by its compatibility with blending operations and mechanized spreading systems, making it a staple in cereal, forage, and oilseed production. Its broader nutrient profile can help soils with sulfur or calcium deficiency, supporting balanced nutrition and improved crop performance.

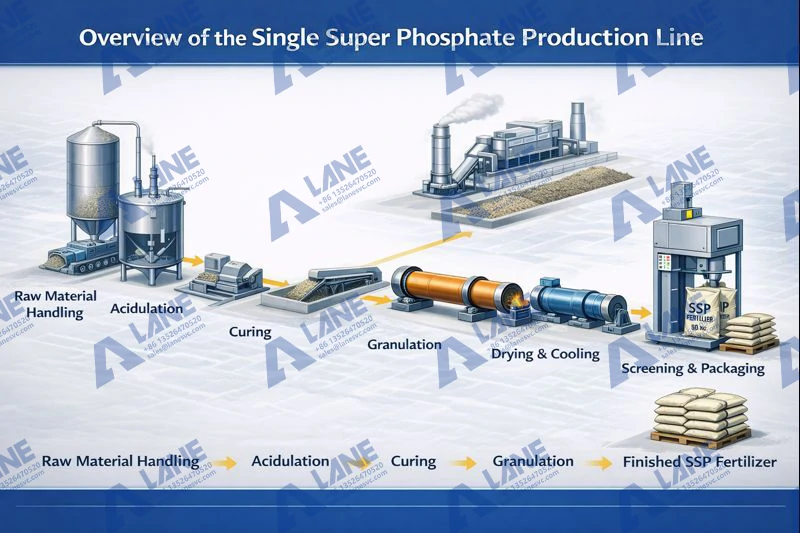

Overview of the SSP Fertilizer Production Line

An SSP fertilizer production line integrates chemical reaction stages, material handling, granulation, and downstream finishing, organized into a continuous workflow. Below is a typical SSP Fertilizer Production Line process sequence in industrial settings:

1. Raw Material Preparation

Phosphate rock, the primary raw material, is crushed and ground to a fine particle size to improve the surface area available for chemical reaction. Precise dosing of sulfuric acid and phosphate rock is critical for consistent nutrient content and efficiency.

Accurate feeding systems and dosing units ensure controlled proportions, which influence final product quality and reaction completeness.

2. Acidulation / Chemical Reaction

In the acidulation reactor, ground phosphate rock reacts with sulfuric acid in a controlled environment. This reaction produces monocalcium phosphate, the key nutrient component of SSP fertilizer, while gypsum remains as a by-product. Temperature, residence time, and acid concentration are critical parameters monitored throughout this stage.

3. Curing and Solidification

Following the initial reaction, the material is often allowed to cure in dedicated curing piles or dens. This stage enables ongoing chemical transformations and stable physical properties to develop in the product. Curing typically lasts several days and contributes to consistent nutrient availability.

4. Granulation

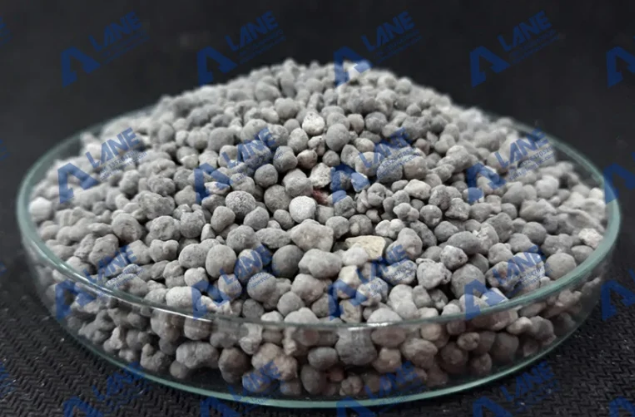

Although SSP can be supplied in powder form, modern industrial practice favors granulation to improve handling, reduce dust, and support mechanized application. Granulators — commonly drum or disc granulators — convert the reacted material into uniform granules with improved physical stability for storage and field application.

5. Drying and Cooling

Granulated SSP contains moisture that must be reduced for stable storage and sale. Dryers remove excess water, and coolers ensure the granules reach ambient temperature without caking or degradation.

6. Screening and Packaging

In the final stages, screening machines separate appropriately sized granules from fines or oversized particles. The finished SSP fertilizer is then packaged in bags or bulk containers, ready for distribution.

Core Equipment in an SSP Fertilizer Production Line

A complete SSP Fertilizer Production Line typically involves the following major machines, each crucial for efficient operation and product quality:

Crushers and Grinders: Reduce phosphate rock to a fine particle size suitable for reaction.

Mixers and Dosing Units: Precisely proportion raw materials before acidulation, ensuring consistent reaction kinetics.

Acidulation Reactors: Facilitate the controlled reaction between phosphate rock and sulfuric acid.

Granulators (Drum or Disc): Produce uniform granules that are easier to handle, store, and apply in the field.

Dryers and Coolers: Reduce moisture and stabilize granules for storage.

Screening Machines: Sort the finished product by particle size and recycle off-spec material.

Packaging Systems: Automate bagging and bulk storage for shipment.

SSP Fertilizer Production Line may also include advanced conveyors, dust collection, and emission control equipment, helping plants meet modern environmental standards.

Design Considerations for SSP Fertilizer Production Line

Designing and building an efficient SSP fertilizer production line involves careful planning across several engineering dimensions:

Process Control and Automation

Automation systems play a central role in monitoring reaction conditions, material flow rates, and equipment status. Process control increases consistency, reduces operator error, and improves overall plant reliability.

Capacity and Scalability

Production capacity planning must balance projected market demand, raw material availability, and capital investment goals. Modular designs allow manufacturers to expand output without large upfront costs.

Environmental and Safety Requirements

SSP production involves acids and gypsum dust that can adversely affect air quality if not properly managed. Modern lines incorporate dust collection systems and controlled exhaust treatment to minimize environmental impact and ensure compliance with regulations.

Layout and Material Flow

A rational plant layout minimizes material transfer distances, enhances worker safety, and improves maintenance accessibility. Clear separation of reaction, granulation, and finishing areas contributes to smoother production flow and reduced downtime.

Applications and Agricultural Value of SSP Fertilizer

Single superphosphate fertilizer remains an important foundation fertilizer in many agricultural systems, especially where soils lack phosphorus or sulfur. Its balanced nutrient profile supports root development, early vegetative growth, and overall crop vigor. Granulated SSP also offers improved ease of handling compared with powdered forms, making it suitable for mechanized application.

In cropping systems where phosphorus and sulfur limitations are common, SSP provides an affordable and effective nutrient source. Producers often blend SSP with other fertilizers such as NPK formulations to meet specific soil test recommendations, enhancing overall nutrient use efficiency.

Comparison and Topical Linkage

For producers considering multiple phosphate fertilizer technologies, it is useful to understand how SSP compares with other phosphate fertilizers such as TSP and DAP in terms of nutrient concentration, application methods, and production processes. These topics are discussed more comprehensively in our article on TSP and DAP fertilizer differences and applications, which provides context on fertilizer selection and industrial manufacturing trade-offs.

Conclusion

An SSP fertilizer production line combines controlled chemical reactions, precision machinery, and process automation to produce high-quality phosphate fertilizer suitable for varied agricultural applications. Modern SSP Fertilizer Production Line design practices emphasize efficiency, environmental compliance, and scalability, ensuring that plants can meet evolving market demands while maintaining operational stability and product quality.

Send a message to us