How LANE SSP Fertilizer Production Line Increases Productivity by 30%? Revealing the secrets behind

In the world of agriculture, Single Super Phosphate (SSP) fertilizer remains a key nutrient source for crops, providing essential phosphorus to enhance soil fertility and promote plant growth. However, the process of manufacturing SSP fertilizer can be complex and resource-intensive, requiring specialized equipment and optimized production techniques. LANE Group, an industry leader in fertilizer production machinery, has engineered an advanced SSP Fertilizer Production Line that promises to increase productivity by up to 30%. But what are the secrets behind this impressive productivity boost?

SSP fertilizer is produced through the chemical reaction between rock phosphate and sulfuric acid. This process results in a high-phosphate product that is ideal for improving crop yields. The basic steps in SSP fertilizer production include:

Crushing Rock Phosphate → Reaction with Sulfuric → AcidGranulation → Drying and Cooling → Screening and Packaging

While this process is standard across the industry, LANE Group has introduced several innovations to significantly enhance productivity and efficiency.

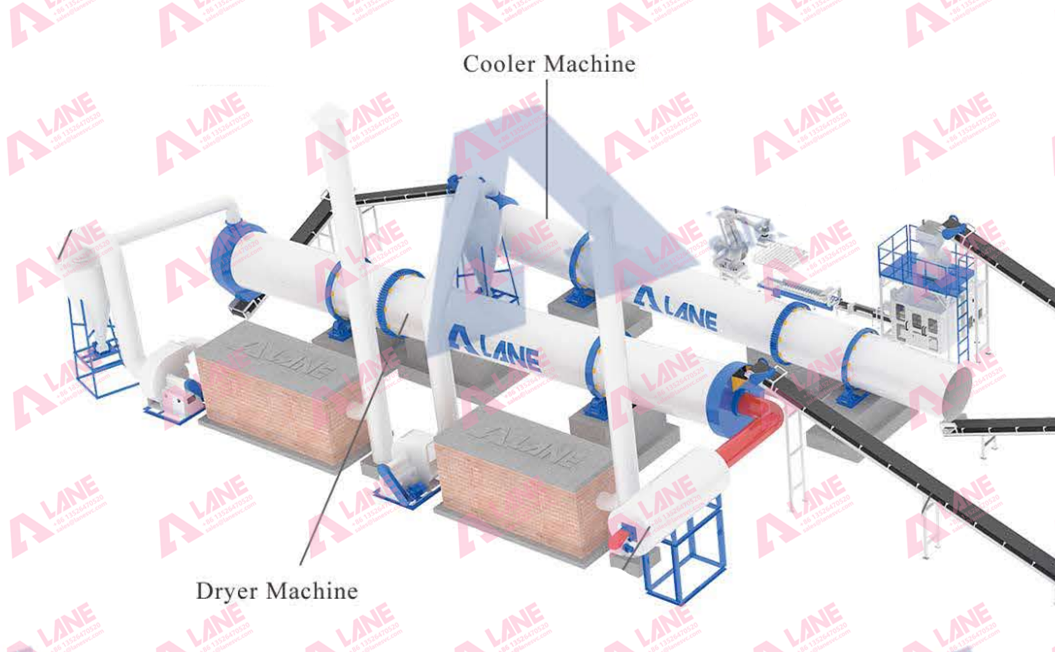

Overview of Production Line

Secret 1: Advanced Rock Phosphate Crusher Technology

One of the key areas where LANE’s SSP Fertilizer Production Line outshines traditional methods is its advanced rock phosphate crusher. The crusher technology employed by LANE ensures a more efficient and fine grinding of phosphate rock, which speeds up the chemical reaction with sulfuric acid. This higher reaction efficiency translates to faster production cycles and a more consistent product quality, contributing to the 30% productivity boost.

The crusher is also built with wear-resistant materials, ensuring long operational life and reducing downtime due to maintenance, further improving overall productivity.

Secret 2: High-Efficiency Reaction Kettle for Optimal Chemical Reactions

The reaction between phosphate rock and sulfuric acid is critical to SSP production, and the efficiency of this reaction directly impacts output. LANE Group’s SSP Fertilizer Production Line incorporates a high-efficiency reaction kettle that optimizes the contact between the powdered rock and sulfuric acid.

Through advanced stirring technology and precise temperature control, the reaction kettle ensures that the chemical process is completed more quickly and with less waste. This improvement reduces the time required for the reaction stage, allowing for higher throughput and increased productivity.

Secret 3: Innovative Granulation Technology

Granulation is a key stage in SSP fertilizer production line, as it determines the final form of the fertilizer product. LANE Group’s innovative granulation technology uses a unique combination of disc and drum granulators to ensure uniform particle size and shape. The dual granulator system not only improves the quality of the final product but also allows for faster granulation processes.

This innovation leads to more consistent granule formation, reducing the amount of waste material and ensuring that more of the raw input is converted into usable fertilizer. As a result, the production line operates more efficiently, contributing to the overall 30% productivity increase.

Secret 4: Energy-Efficient Drying and Cooling Systems

In traditional SSP fertilizer production line, drying and cooling are energy-intensive processes that can slow down overall production. However, LANE Group has designed energy-efficient drying and cooling systems that significantly reduce the time required for these stages.

The drying system uses advanced heat recovery technology, capturing excess heat from the production process and using it to dry the fertilizer granules. This not only reduces energy consumption but also speeds up the drying process, leading to faster production cycles. Similarly, the cooling system is designed to optimize airflow, ensuring that granules are cooled quickly and evenly, ready for packaging sooner.

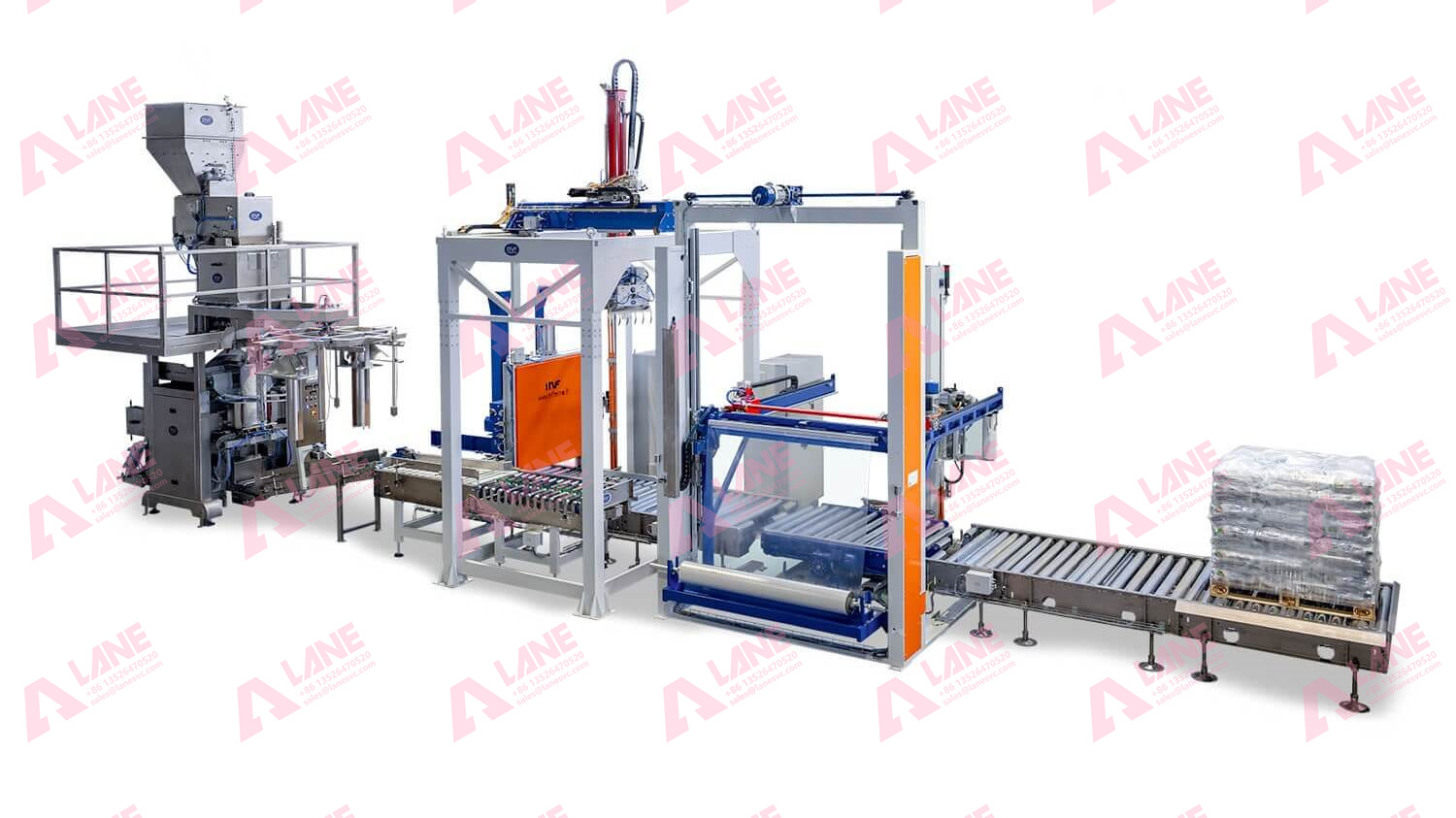

Secret 5: Automated Quality Control and Packaging

LANE’s SSP Fertilizer Production Line incorporates automated quality control and packaging systems that ensure consistent product quality while streamlining the final stages of production. The automated screening system detects and removes any off-spec granules, ensuring that only high-quality fertilizer reaches the packaging stage.

The automated packaging system is capable of handling large volumes of product with minimal manual intervention, reducing labor costs and further increasing production speed. This level of automation is crucial in maintaining the 30% productivity increase, as it eliminates bottlenecks in the final stages of production.

Secret 6: Real-Time Monitoring and Control Systems

Another secret to LANE’s SSP Fertilizer Production Line enhanced productivity lies in its real-time monitoring and control systems. These advanced systems allow operators to monitor every aspect of the production line in real-time, from raw material input to final product output. The system provides detailed data on equipment performance, chemical reactions, and production speed, enabling operators to make immediate adjustments when necessary.

This real-time control minimizes downtime, reduces waste, and ensures that the production line is always operating at peak efficiency. The ability to quickly respond to potential issues is a key factor in achieving the 30% productivity boost.

Secret 7: Modular and Scalable Design

Finally, LANE Group’s SSP Fertilizer Production Line is designed with a modular and scalable structure. This allows fertilizer producers to start with a basic setup and gradually expand their production capacity as needed. The modular design ensures that additional equipment can be seamlessly integrated into the existing production line without causing significant downtime.

The scalability of the production line makes it a cost-effective solution for fertilizer manufacturers looking to increase their output without investing in an entirely new production facility. This adaptability contributes to long-term productivity gains and helps producers meet growing demand.

Conclusion: A New Era of Productivity in SSP Fertilizer Production

LANE Group’s SSP Fertilizer Production Line represents a major leap forward in fertilizer manufacturing technology. By integrating advanced crushing, granulation, drying, cooling, and automation systems, LANE has created a production line that delivers a remarkable 30% productivity increase. This boost is the result of years of research, development, and engineering expertise, making LANE Group a trusted partner for fertilizer producers worldwide.

For companies looking to improve their SSP fertilizer production efficiency, reduce costs, and meet growing market demand, LANE Group’s innovative solutions provide the ideal pathway to success. With its cutting-edge technology and commitment to excellence, LANE Group is leading the way in the future of fertilizer production.

About LANE

Send a message to us