SSP Fertilizer Manufacturing Plant: Practical Guide to Single Super Phosphate Production

SSP Fertilizer Manufacturing Plant Overview

An SSP fertilizer manufacturing plant is designed to produce single super phosphate fertilizer by reacting phosphate rock with sulfuric acid. SSP is widely used as a phosphorus fertilizer, especially in regions with acidic or phosphorus-deficient soils.

From an industrial perspective, SSP production is considered a mature and reliable process. However, stable operation still depends on proper raw material handling, process control, and equipment selection. A well-designed SSP fertilizer manufacturing plant focuses on consistency rather than complexity.

What Is an SSP Fertilizer Manufacturing Plant?

An SSP fertilizer manufacturing plant is a processing system that converts phosphate rock into plant-available phosphorus fertilizer. The core reaction involves sulfuric acid and finely ground phosphate rock.

Unlike highly complex compound fertilizer plants, SSP plants operate with a relatively straightforward process. This simplicity makes SSP fertilizer manufacturing attractive for producers seeking stable output and moderate investment levels.

Most SSP fertilizer manufacturing plants can operate as standalone facilities or as part of a larger fertilizer production complex.

Why SSP Fertilizer Is Still Widely Used

Despite the development of compound and specialty fertilizers, SSP remains relevant in modern agriculture. This is mainly due to its agronomic and economic advantages.

Key reasons for continued SSP usage include:

High phosphorus availability

Presence of calcium and sulfur nutrients

Suitable for acidic soils

Lower production cost compared to complex fertilizers

Simple application for farmers

For fertilizer manufacturers, SSP offers stable market demand and predictable production performance.

SSP Fertilizer Manufacturing Process Explained

- Phosphate Rock Preparation

The process begins with phosphate rock crushing and grinding. Fine particle size improves reaction efficiency with sulfuric acid.

Uniform feed material helps ensure consistent chemical reaction and product quality.

- Acidulation Reaction

Ground phosphate rock is mixed with sulfuric acid in a reactor or mixer. This reaction converts insoluble phosphate into water-soluble monocalcium phosphate.

Reaction control is critical. Poor acid distribution can lead to incomplete conversion and quality issues.

- Curing and Maturation

After the reaction, the material is discharged to a curing area. Curing allows the chemical reaction to complete and stabilizes the fertilizer structure.

Curing time varies depending on raw materials and process conditions. Adequate curing improves phosphorus availability and reduces free acid content.

- Crushing and Screening

Cured SSP material is crushed and screened to achieve the desired particle size. Oversized particles are recycled back into the crushing system.

This step ensures uniform granule size for packaging and application.

- Packaging and Storage

Finished SSP fertilizer is conveyed to packaging or bulk storage systems. Proper storage conditions help prevent moisture absorption and caking.

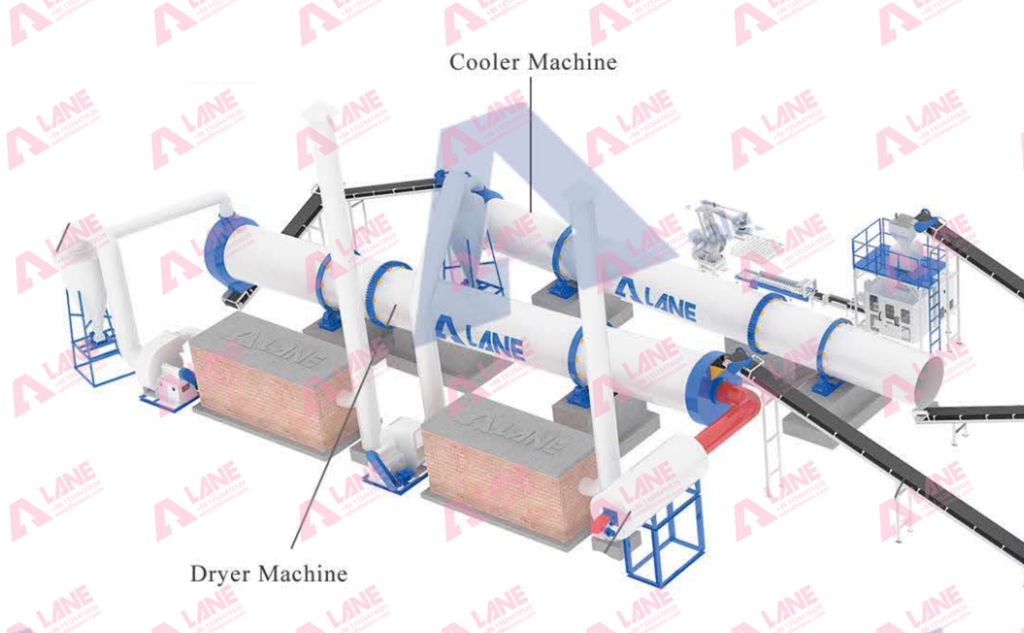

Main Equipment in an SSP Fertilizer Manufacturing Plant

A standard SSP fertilizer manufacturing plant includes the following equipment:

Phosphate rock crusher and grinder

Sulfuric acid storage and dosing system

Reactor or mixer

Curing area or curing system

Dust collection and ventilation system

Equipment layout should be planned to ensure smooth material flow and easy maintenance.

Key Factors Affecting SSP Fertilizer Quality

Several factors directly influence SSP fertilizer quality during production:

Phosphate rock grade and consistency

Sulfuric acid concentration

Mixing uniformity

Curing time and conditions

Moisture control

Plants that maintain stable raw material quality generally achieve more consistent product performance.

Environmental and Safety Considerations

SSP fertilizer manufacturing involves acidic materials and fine dust. Environmental and safety management is therefore essential.

Common control measures include:

Acid-resistant equipment materials

Dust collection systems

Proper ventilation

Wastewater management

Operator safety training

A well-managed SSP fertilizer manufacturing plant minimizes environmental impact while maintaining stable output.

Integration with Other Fertilizer Production Lines

An SSP fertilizer manufacturing plant can be integrated with other fertilizer systems such as compound fertilizer or granulation lines. In this configuration, SSP acts as a phosphorus source for blended or granulated products.

This integration improves raw material utilization and allows manufacturers to diversify product offerings without major infrastructure changes.

Maintenance and Operational Considerations

Routine maintenance is essential for long-term plant stability. Common maintenance tasks include checking acid pipelines, inspecting mixers, and cleaning dust collection systems.

Preventive maintenance reduces unexpected downtime and extends equipment service life. From an operational standpoint, consistent monitoring is often more effective than frequent adjustments.

Choosing the Right SSP Fertilizer Manufacturing Plant Supplier

When selecting an SSP fertilizer manufacturing plant supplier, experience matters more than theoretical capacity. Manufacturers should evaluate completed projects, process reliability, and after-sales support.

A reliable supplier should provide:

Process design based on local raw materials

Durable equipment selection

Installation and commissioning services

Operator training and technical support

These factors directly affect startup success and long-term operation.

Conclusion

An SSP fertilizer manufacturing plant remains a practical and reliable solution for producing phosphorus fertilizer. With proper design, stable operation, and suitable equipment selection, SSP production offers consistent quality and long-term economic benefits. Focus on process control and raw material management is key to sustained performance.

For internationally recognized quality benchmarks and nutrient specifications relating to single superphosphate and other fertilizer products, refer to the FAO fertilizer specifications for SSP and other fertilizers, which provide standardized definitions and quality criteria used in global agricultural trade and production.

Call to Action

If you are planning to build or upgrade an SSP fertilizer manufacturing plant, early technical evaluation can reduce risks and improve project efficiency. Professional process design and equipment support help ensure stable operation and consistent fertilizer quality over the long term.

Ready to choose the right fertilizer solution? Contact LANE today to learn more about .

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Send a message to us