Reducing Costs, Increasing Yields: The Benefits of SSP Bulk Fertilizer Lines

In modern agriculture, efficient nutrient delivery is essential for maximizing crop yields and controlling production costs. Single Super Phosphate (SSP) bulk fertilizer lines provide a cost-effective solution to meet these demands. SSP is widely used to improve phosphorus levels in soils, supporting healthy root development, flowering, and crop yields. SSP bulk fertilizer lines streamline the production and supply of this essential fertilizer, ensuring farmers have access to affordable, high-quality phosphorus fertilizers.

What is SSP Fertilizer?

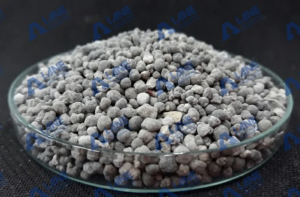

Single Super Phosphate (SSP) is a phosphorus-rich fertilizer made by reacting phosphate rock with sulfuric acid. It contains around 16-20% phosphorus (in the form of P₂O₅) and also provides additional nutrients like sulfur and calcium. SSP’s dual benefit of supplying both phosphorus and sulfur makes it an effective choice for crops grown in soils with nutrient deficiencies.

SSP is used widely for a variety of crops, including cereals, oilseeds, pulses, and vegetables, promoting healthy root systems and boosting productivity.

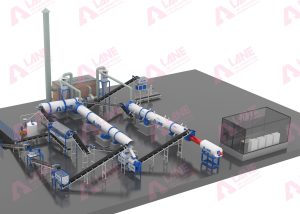

How SSP Bulk Fertilizer Lines Work

SSP bulk fertilizer lines are specialized production systems that transform raw phosphate rock into SSP fertilizers through a series of carefully controlled processes. Below is an overview of how SSP bulk fertilizer lines operate:

1. Raw Material Preparation

The process begins with the extraction and preparation of raw phosphate rock. The rock is crushed and ground into fine particles, ensuring better chemical reactivity with sulfuric acid.

2. Acidulation Process

The core of the SSP production process involves reacting the phosphate rock with sulfuric acid in a chemical reactor. The acid breaks down the phosphate, releasing water-soluble phosphorus. This chemical transformation results in the formation of SSP, with gypsum (calcium sulfate) as a byproduct.

3. Granulation and CuringThe freshly produced SSP is moist and must undergo granulation to create uniform-sized particles. The fertilizer is then spread out for curing, a process that allows the SSP to mature and stabilize over several days. During this time, the fertilizer becomes more effective and easier to handle.

4. Drying and Cooling

Once cured, the SSP granules are dried to remove excess moisture and prevent clumping. Cooling systems bring the granules to a stable temperature, ensuring product quality during storage and transportation.

5. Screening and Bulk Packaging

The final product is screened to ensure uniform granule size. The SSP is then packaged in large bags or bulk containers for distribution. Bulk packaging reduces packaging waste, lowers transport costs, and makes SSP more accessible for large-scale agricultural operations.

The Benefits of SSP Bulk Fertilizer Lines

1. Cost-Effective Fertilizer Production

SSP is one of the most affordable sources of phosphorus, making it ideal for farmers seeking high-quality fertilizers at lower costs. Bulk fertilizer lines further enhance cost-efficiency by minimizing production waste and streamlining packaging and distribution.

2. Improved Crop Yields and Quality

SSP fertilizer promotes root development and supports the early establishment of crops. The phosphorus content helps plants grow strong and healthy, while the sulfur component improves crop quality by aiding in protein synthesis and enzyme production. With regular use of SSP, farmers experience higher yields and better-quality produce.

3. Dual Nutrient Benefits

In addition to phosphorus, SSP supplies essential sulfur, which is often deficient in soils. Sulfur plays a crucial role in crop metabolism and enhances the effectiveness of nitrogen fertilizers, improving overall nutrient uptake and plant growth.

4. Better Nutrient Availability

The phosphorus in SSP is in a water-soluble form, ensuring it is readily available to plant roots. This makes it highly effective during the early stages of crop growth, especially for crops that rely heavily on phosphorus for root establishment and flowering.

5. Reduced Environmental Impact

SSP bulk fertilizer lines are designed to optimize resource use, reducing waste and emissions during production. Additionally, SSP fertilizers reduce nutrient runoff and leaching, helping farmers adopt more sustainable farming practices while minimizing environmental risks.

Applications of SSP Fertilizer in Agriculture

1. Cereal Crops

SSP fertilizers are widely used in the cultivation of wheat, rice, maize, and barley, where phosphorus promotes early root growth and boosts grain yield.

2. Oilseeds and Pulses

Oilseed crops like canola and sunflower benefit from the sulfur content in SSP, which enhances oil quality and increases crop yield. Pulses such as chickpeas and lentils also thrive with SSP, as it supports nitrogen fixation and root nodulation.

3. Vegetables and Fruits

Farmers use SSP fertilizers in vegetable farms to improve flowering and fruit development. Fruit orchards also benefit from phosphorus-rich fertilizers, which enhance fruit size and sweetness.

4. Pastures and Forage Crops

SSP is applied to pasturelands to promote grass growth and improve feed quality for livestock. The dual nutrient content of phosphorus and sulfur ensures long-term soil fertility and better forage yields.

Innovations in SSP Bulk Fertilizer Lines

1. Automated Production Systems

Modern SSP bulk fertilizer lines integrate automated systems to monitor and control each stage of production, from acidulation to packaging. Automation ensures consistent product quality, reduces labor costs, and improves overall efficiency.

2. Energy-Efficient Technologies

Energy-efficient dryers and heat recovery systems are being adopted to minimize energy consumption during the drying process. These innovations lower operational costs and reduce the carbon footprint of fertilizer production.

3. Custom Fertilizer Blends

Some SSP bulk fertilizer lines allow for customization, blending SSP with other nutrients like nitrogen or potassium. This flexibility provides farmers with tailored solutions to address specific crop and soil needs.

4. Bulk Packaging for Large-Scale Farming

Bulk packaging reduces packaging waste and lowers transportation costs, making SSP fertilizers more accessible to large agricultural operations. Bulk fertilizer solutions also simplify logistics for farmers, enabling them to store and apply fertilizers more efficiently.

Challenges and Solutions in SSP Production

1. Raw Material Availability

The availability of high-quality phosphate rock is critical to SSP production. Fertilizer manufacturers are exploring partnerships with phosphate mines and investing in sustainable sourcing practices to ensure a steady supply of raw materials.

2. Handling and Storage

SSP fertilizers are prone to moisture absorption, which can affect their quality. Proper storage facilities with moisture control systems ensure that the fertilizer remains stable during transport and storage.

3. Market Awareness

Some farmers may be unfamiliar with the benefits of SSP fertilizers compared to other phosphorus sources. Educational initiatives and demonstration plots can help promote the adoption of SSP in regions where phosphorus deficiency limits crop yields.

Conclusion

SSP Bulk Fertilizer Lines are transforming the agricultural landscape by providing farmers with affordable, high-quality fertilizers that enhance crop yields and reduce costs. With their dual nutrient benefits, SSP fertilizers play a crucial role in promoting sustainable farming practices and improving soil fertility.

Innovations in production technology and energy efficiency are making SSP bulk fertilizer lines more sustainable and cost-effective. By adopting these advanced systems, manufacturers can ensure a reliable supply of SSP fertilizers to meet the growing global demand for food production.

As agriculture moves toward greener practices, SSP fertilizers will remain a valuable tool for boosting productivity while minimizing environmental impact. With SSP bulk fertilizer lines at the forefront of fertilizer manufacturing, farmers can achieve better yields, lower costs, and more sustainable agricultural outcomes.

Send a message to us