Spray Tower

In modern industrial applications, the need for effective gas treatment and pollution control has never been more critical. Industries that deal with harmful emissions or require precise chemical reactions rely on equipment like the Spray Tower to manage and control their processes. LANE Group’s Spray Tower technology is at the forefront of this industry, offering cutting-edge solutions that enhance efficiency, safety, and environmental protection.

Key Features of LANE Group’s Spray Tower

LANE Group’s Spray Tower is designed with advanced features that make it highly effective in treating gas streams and controlling emissions. Here are some of the standout features:

- High-Efficiency Scrubbing: The Spray Tower is engineered for maximum scrubbing efficiency, with a design that ensures thorough contact between the gas and the liquid spray. This results in the effective removal of contaminants, such as sulfur dioxide (SO₂), nitrogen oxides (NOx), particulate matter, and other pollutants.

- Versatile Liquid Options: Depending on the application, the Spray Tower can use various scrubbing liquids, including water, chemical solutions, or alkaline reagents. This versatility allows it to be tailored to different industrial processes, ensuring optimal performance.

- Corrosion-Resistant Materials: To handle the harsh chemicals and acidic gases often present in industrial processes, the Spray Tower is constructed from corrosion-resistant materials, such as stainless steel, fiberglass-reinforced plastic (FRP), or high-density polyethylene (HDPE). This ensures long-term durability and reliable operation.

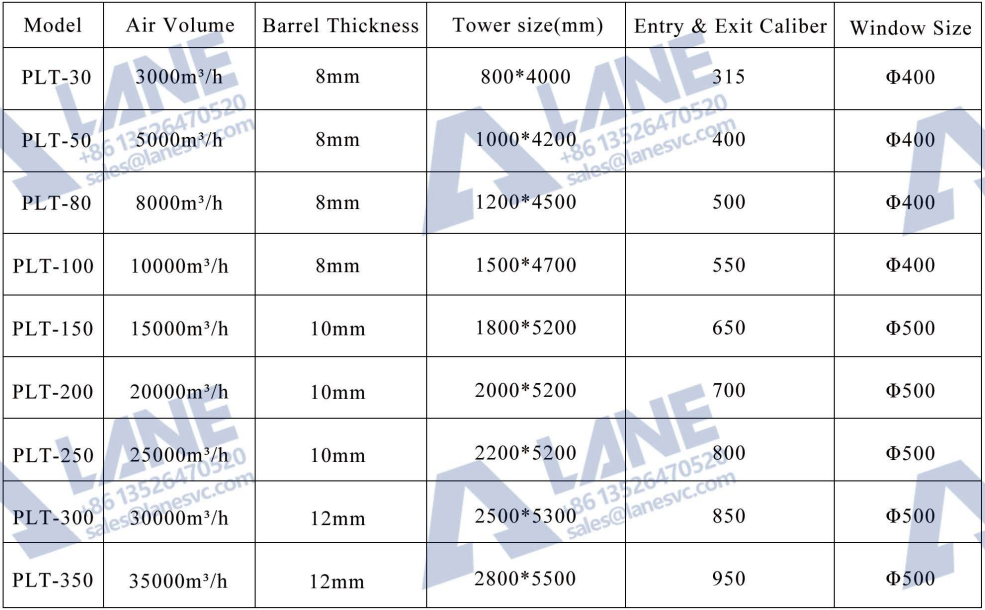

- Customizable Design: LANE Group offers customizable Spray Towers to meet the specific needs of different industries. Whether you require a compact design for a limited space or a large-capacity tower for high-volume processing, LANE Group can provide a solution that fits your requirements.

- Advanced Control Systems: The Spray Tower is equipped with state-of-the-art control systems that allow for precise monitoring and adjustment of operating parameters, such as liquid flow rate, pressure, and temperature. This ensures that the system operates efficiently and consistently meets emission standards.

- Low Maintenance: Designed with ease of maintenance in mind, LANE Group’s Spray Tower features accessible components and a straightforward design, reducing downtime and maintenance costs.

Application

LANE Group’s Spray Tower is used in a wide range of industries where gas treatment and pollution control are essential. Here are some key applications:

- Chemical Manufacturing: In chemical plants, the Spray Tower is used to scrub harmful gases generated during production processes, ensuring that emissions are within safe and regulatory limits.

- Fertilizer Production: Fertilizer manufacturing often involves the release of acidic gases and particulate matter. The Spray Tower effectively captures and neutralizes these emissions, protecting the environment and workers’ health.

- Energy Generation: Power plants, especially those that burn fossil fuels, generate significant amounts of pollutants, including sulfur dioxide and particulate matter. The Spray Tower plays a crucial role in reducing these emissions, helping plants comply with stringent environmental regulations.

- Waste Incineration: In waste-to-energy plants, the Spray Tower is used to treat flue gases, removing harmful substances before they are released into the atmosphere.

- Metal Processing: In industries like steelmaking, the Spray Tower is used to control dust and gaseous emissions, ensuring cleaner and safer operations.

Benefits of Using LANE Group’s Spray Tower

Choosing LANE Group’s Spray Tower offers several key benefits for industrial operations:

- Improved Environmental Compliance: With its high scrubbing efficiency, the Spray Tower helps industries meet stringent environmental regulations, reducing the risk of fines and operational shutdowns due to non-compliance.

- Enhanced Safety: By effectively controlling harmful emissions, the Spray Tower protects workers and nearby communities from exposure to toxic substances, contributing to a safer working environment.

- Cost-Effective Operation: LANE Group’s Spray Tower is designed for efficient operation, minimizing energy and water consumption while maximizing pollutant removal. This leads to lower operational costs and a better return on investment.

- Custom Solutions: LANE Group works closely with clients to design Spray Towers that meet their specific needs, ensuring optimal performance in diverse industrial settings.

- Sustainability: By reducing emissions and improving air quality, the Spray Tower contributes to more sustainable industrial practices, aligning with global efforts to combat climate change and protect the environment.

If you want to get more imformation, Please contact us!