How to Control Chloride Levels During SOP Production

Chloride levels are a critical factor in producing Sulfate of Potash (SOP) fertilizer, as high chloride content can negatively impact the quality of the product and its suitability for chloride-sensitive crops. This guide explores methods to control chloride levels during SOP production, ensuring the product meets agricultural standards and supports healthy plant growth.

In SOP production, controlling chloride levels is essential because high chloride can harm crops that are sensitive to it, such as potatoes, tomatoes, and tobacco. SOP is preferred over other potassium sources for these crops due to its low chloride content. Chloride levels are particularly important in SOP derived from natural ores or produced through chemical processes, as these materials often contain varying chloride concentrations.

Sources of Chloride in SOP Production

- Natural Ore Extraction

- Some SOP is produced from natural minerals, which can have inherent chloride.

- Processes like mining potassium-rich minerals (e.g., kainite or langbeinite) involve initial materials that might have chloride impurities.

- Chemical Conversion Processes

- Chloride often enters SOP production during the reaction between potassium chloride (KCl) and sulfuric acid (H₂SO₄), releasing hydrochloric acid (HCl) as a byproduct.

- Additional chloride contaminants may arise from water sources or reactant impurities.

Methods to Control Chloride Levels During SOP Production

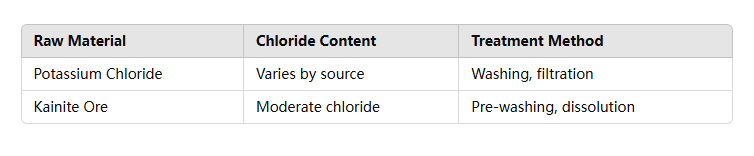

Raw Material Selection and Quality Control

- High-Purity Potassium Sources

- Using high-quality potassium chloride as a raw material can minimize initial chloride levels.

- Regularly testing raw materials ensures that any impurities, including chloride, are within acceptable limits.

- Pre-Treatment of Materials

- Raw potassium chloride can undergo washing to reduce surface chloride levels before processing.

- Techniques like solution purification help eliminate soluble chlorides from mined minerals.

Process Modifications

- Optimizing Reaction Conditions

- Carefully controlling the temperature and concentration of sulfuric acid in the conversion reaction can minimize the formation of HCl gas and reduce chloride contamination in the final SOP product.

- Lower reaction temperatures, combined with controlled sulfuric acid concentration, have been shown to decrease chloride release.

- Closed-System Reaction Chambers

- Implementing closed-system reactors prevents external chloride from entering during production and allows more precise management of chloride byproducts.

Impact: Controlled reaction conditions minimize the risk of chloride contamination and improve SOP quality.

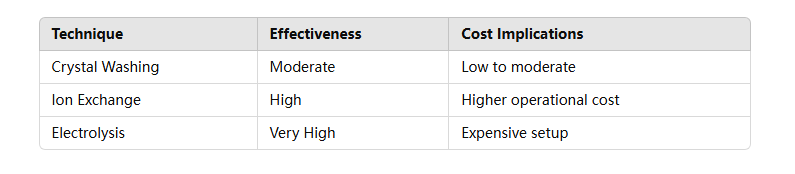

Chloride Removal Techniques

- Washing and Filtering SOP Crystals

- Post-reaction SOP crystals can be washed in purified water to dissolve and remove residual chloride from the crystal surface.

- Repeated washing or rinsing reduces chloride levels to meet strict quality standards.

- Ion Exchange and Electrolysis

- Advanced methods like ion exchange and electrolytic separation selectively remove chloride ions from solution, leaving purified SOP.

- These methods are effective but may add production costs, often used in facilities requiring ultra-low chloride SOP.

Quality Assurance and Testing

- Regular Chloride Testing

- Routine testing for chloride levels ensures that SOP meets required specifications.

- Conduct tests at multiple stages, including after initial raw material preparation, during the reaction, and after final washing.

- Analytical Techniques

- Techniques like ion chromatography and titration are commonly used to measure chloride concentration.

- Employing advanced testing methods helps maintain quality and adjust processes when needed.

Impact: Quality assurance measures provide data to improve processes and detect any deviations in chloride levels.

Benefits of Chloride Control in SOP Production

- Enhanced Product Quality

- Lower chloride content in SOP increases its market value and makes it suitable for chloride-sensitive crops.

- Improved Crop Compatibility

- SOP with low chloride content is gentler on soil, supporting long-term agricultural health.

- Increased Production Efficiency

- With better control over chloride levels, production becomes more efficient, reducing waste and improving SOP purity.

- Environmental Benefits

- Proper chloride control reduces waste chloride byproducts, lowering environmental impact.

Conclusion

Controlling chloride levels during SOP production is vital to produce a high-quality, low-chloride fertilizer suitable for a variety of crops. By carefully selecting raw materials, optimizing process conditions, using effective chloride removal techniques, and adhering to strict quality control, manufacturers can produce superior SOP that meets agricultural standards.

For SOP producers, investing in chloride management strategies translates into higher-quality products, better market positioning, and improved sustainability. Ensuring low chloride content aligns with agricultural demands, offering farmers a reliable potassium source for growing healthy, chloride-sensitive crops.

Send a message to us