Small Fertilizer Plant Cost Explained from an Engineering Perspective

Why Small Fertilizer Plant Cost Varies So Widely

Small fertilizer plant cost does not follow a fixed pricing model. Even plants with similar capacities can show large differences in total investment. The main reason is that “small” refers to scale, not to technical simplicity.

A small fertilizer plant may still include crushing, mixing, granulation, drying, cooling, screening, and packaging systems. The final cost depends on how these processes are configured and how much flexibility the plant is designed to provide.

Understanding small fertilizer plant cost requires looking beyond equipment price and examining the entire production system.

Capacity Definition and Its Cost Impact

Production capacity is the first factor that shapes small fertilizer plant cost. Small plants are typically designed for local or regional supply, but capacity can still range significantly.

A plant producing 5–10 tons per hour has very different equipment requirements compared to one producing 1–2 tons per hour. Higher capacity increases equipment size, power consumption, and foundation requirements.

Oversizing capacity often leads to unnecessary investment. Proper capacity matching helps control cost while maintaining stable output.

Equipment Configuration in Small Fertilizer Plants

Equipment is usually the largest single contributor to small fertilizer plant cost. However, the configuration matters more than the number of machines.

A basic configuration includes:

Screening and recycling

Small plants often prioritize reliability and ease of maintenance over high automation. Compact equipment layouts reduce installation time and simplify operation.

Selecting equipment based on actual raw material properties avoids frequent breakdowns and excessive maintenance expenses.

Granulation Method and Cost Differences

Granulation is a key cost driver in small fertilizer plants. Different granulation methods lead to different investment levels and operating complexity.

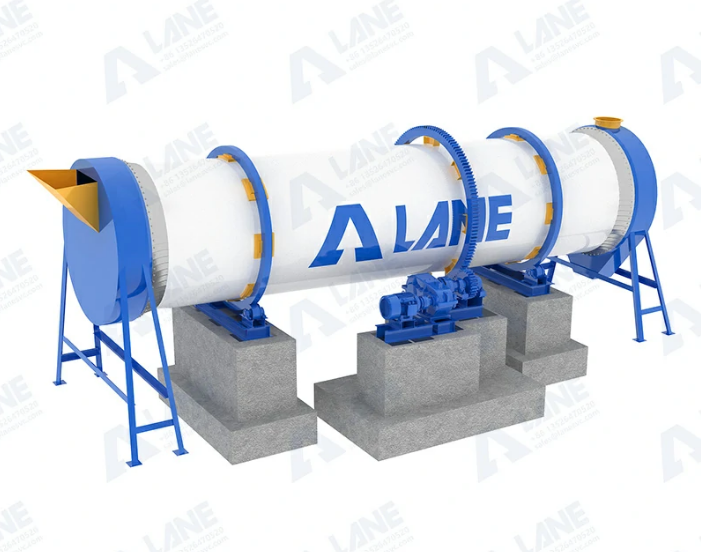

Drum granulation systems are suitable for continuous operation and offer stable granule quality. Disc granulators require lower initial investment but may have lower throughput consistency.

The choice of granulation method directly affects small fertilizer plant cost and should align with product type and quality expectations.

Civil Construction and Site Conditions

Civil construction cost is often underestimated during early planning. Even for small fertilizer plants, foundations must support rotating equipment and thermal systems.

Site conditions such as soil strength, space limitations, and access roads influence construction cost. Efficient layout planning reduces material handling distance and avoids unnecessary structural work.

Optimizing civil design is one of the most effective ways to reduce small fertilizer plant cost without affecting production quality.

Utility Systems and Energy Consumption

Utilities are essential to plant operation and contribute to both capital and operating expenses. Electricity, fuel, water, and dust collection systems must be considered together.

Energy-efficient equipment reduces long-term operating cost but may slightly increase initial investment. In regions with high energy prices, this trade-off becomes critical.

A realistic evaluation of utility availability helps prevent underestimation of small fertilizer plant cost.

Labor, Operation, and Maintenance Considerations

Small fertilizer plants typically require fewer operators, but labor cost still affects long-term economics. Operator skill level directly impacts equipment lifespan and process stability.

Maintenance cost depends on wear parts, operating discipline, and spare parts management. Poor maintenance planning often leads to frequent shutdowns and higher repair expenses.

Including maintenance strategy in early planning improves control over total small fertilizer plant cost.

Flexibility vs Cost Control in Small Plants

One advantage of small fertilizer plants is production flexibility. They can adapt to changing market demand more easily than large facilities.

However, higher flexibility often requires more complex equipment arrangements. Adjustable batching systems and multi-purpose equipment increase initial cost but improve market responsiveness.

Balancing flexibility and cost control is a key decision for small fertilizer plant investors.

New Plant Construction vs Existing Facility Upgrade

Small fertilizer plant cost differs significantly between new construction and upgrading an existing facility. New plants offer optimized layout but require full investment.

Upgrading existing facilities reduces civil construction cost but may involve compromises in equipment arrangement and expansion potential.

A technical evaluation helps determine which option provides better return on investment.

How to Estimate Small Fertilizer Plant Cost Accurately

Accurate cost estimation requires clear technical input. Vague project descriptions often lead to unrealistic budgets.

Key information includes:

Target fertilizer type

Raw material characteristics

Desired capacity

Local utility conditions

Environmental requirements

Providing accurate data allows suppliers to propose realistic and optimized solutions.

For an independent and authoritative perspective on fertilizer production systems and cost considerations, readers may refer to the FAO fertilizer production and cost reference, which provides technical insights into fertilizer plant design, operating conditions, and cost-related factors.

Conclusion

Small fertilizer plant cost is influenced by multiple interconnected factors. Equipment selection, capacity planning, civil construction, utilities, and maintenance strategy all contribute to total investment.

Rather than focusing only on initial price, investors should evaluate long-term operating stability and cost control. A well-designed small fertilizer plant offers a practical entry point into fertilizer production with manageable risk and sustainable performance.

Ready to choose the right fertilizer solution? Contact LANE today to learn more about .

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Send a message to us