Single Super Phosphate Production Line: Enhancing Phosphorus Supply in Agriculture

In today’s competitive fertilizer market, having an efficient and advanced Single Super Phosphate Production Line is undoubtedly the key to open the door of success. Single Super Phosphate is an important variety of phosphorus fertilizer, with a variety of nutrient content and characteristics, mainly as sulfur fertilizer, calcium fertilizer and compound fertilizer mother material.

Single Super Phosphate belongs to a kind of common chemical phosphate fertilizer, which is mainly produced by decomposing phosphate rock by sulfuric acid. Its main components include calcium dihydrogen phosphate (Ca(H2PO4)2-H2O) and a small amount of calcium sulfate (CaSO4), of which calcium dihydrogen phosphate accounts for 40-50% of the weight of the fertilizer, while calcium sulfate accounts for about 40%. In addition, Single Super Phosphate contains small amounts of anhydrous calcium sulfate and free acid.

The R&D team of LANE Group announced the launch of Single Super Phosphate production line. Compared with other production lines, Lane Group’s Single Super Phosphate production line has the advantages of low pollution, high efficiency, high output and low energy consumption.

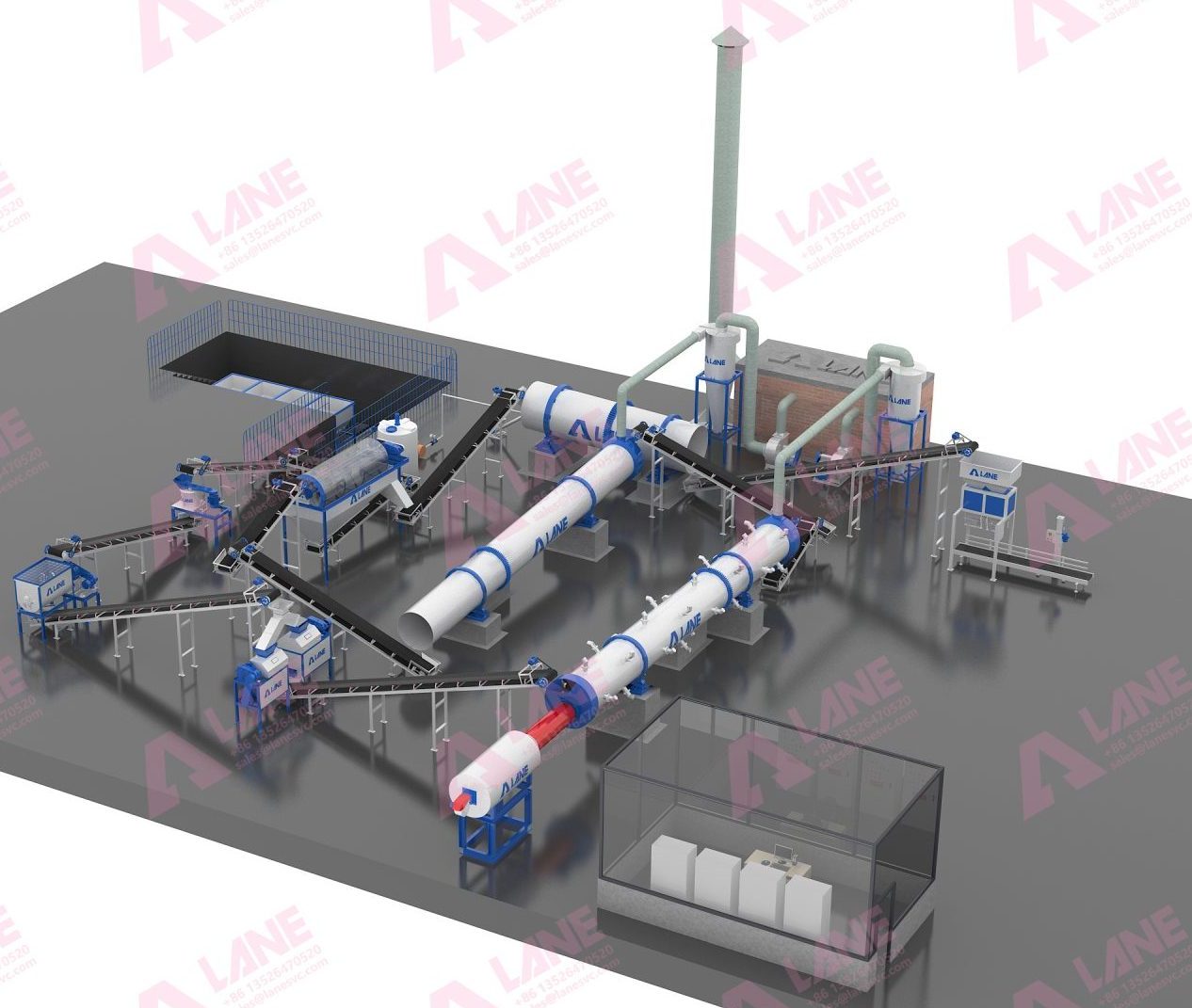

Main Components of Single Super Phosphate Production Line

The production of Single Super Phosphate fertilizers relies on the reaction of phosphate rock with sulfuric acid, which in turn results in the granulation of the resulting Single Super Phosphate.

- Raw Material

Phosphate Rock: The primary raw material is phosphate rock, which is finely ground to ensure better reaction with acid.

Sulfuric Acid: Used to react with phosphate rock, sulfuric acid is a critical component in the production of Single Super Phosphate. - Chemical Reaction

Reactor: The finely ground phosphate rock is mixed with sulfuric acid in a reactor, where the chemical reaction takes place, producing phosphoric acid and calcium sulfate (gypsum).

Granulation: The mixture is then granulated to create small, uniform particles of SSP, which makes it easier to handle and apply. - Curing

Curing Piles: The granulated SSP is stored in curing piles for a few weeks to allow the chemical reaction to complete. This process ensures that the fertilizer is stable and ready for use. - Screening and Crushing

Screening: After curing, the SSP is screened to separate fine particles from larger granules.

Crushing: Any oversized particles are crushed and recycled back into the process to ensure consistent product quality. - Storage and Packaging

Storage: The finished SSP is stored in large silos or warehouses until it is ready to be packaged.

Packaging: The product is packaged in bags or bulk containers for distribution to the agricultural market.

This is the main production process of the Single Super Phosphate Production Line. If you want to know more, welcome to visit our website or leave us a message, our sales manager will get in touch with you as soon as possible.

Advantages of Lane Group Single Super Phosphate Production Line

Henan Lane Heavy Industry Machinery Technology Co, Ltd. is a fertilizer industry leader certified by Alibaba and a machine supplier for Africa’s 10000 ton annual national fertilizer project. The Single Super Phosphate Production Line have the follow advantages.

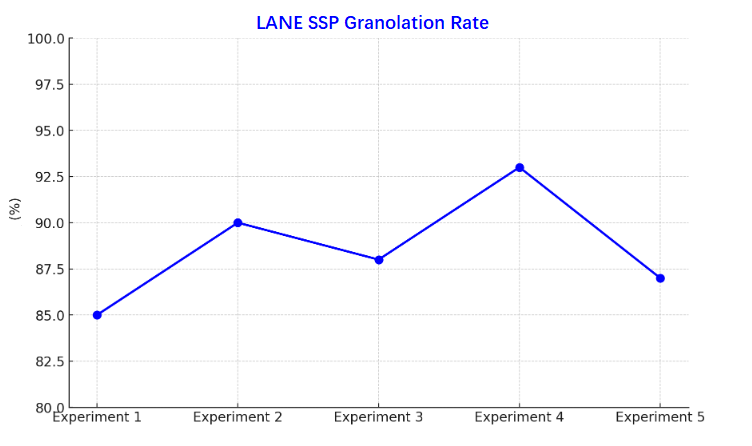

- High granulation rate: After experiments and tests, the granulation rate of Single Super Phosphate production line of Lane Group reaches 85%-95%. This result is due to Lane Group’s high demands on the production of the equipment.

- Low Pollution: The reaction between sulfuric acid and phosphate rock in Single Super Phosphate production line will generate exhaust gas, Lane Group added exhaust gas recovery device in SSP production line, which greatly reduces the environmental pollution.

- Good fertilizer effect: Single Super Phosphate fertilizer produced by Lane Group has the characteristics of fast acting, good fertilizer effect and continuous effect, which can help customers better fertilize their crops and get better effect.

LANE’s Warm Tips

In the process of using Single Super Phosphate fertilizer, there are the following precautions, follow the precautions to use can play the best effect of fertilizer.

- Mixed with organic fertilizer: When mixed with organic fertilizers, the phosphorus in Single Super Phosphate is more readily absorbed by plants, thus increasing the utilization rate of the fertilizer.

- Avoid mixing with alkaline fertilizers: Since Single Super Phosphate is slightly acidic, mixing with alkaline fertilizers will reduce the effectiveness of fertilizer.

- Avoid direct contact with seeds: when used as seed fertilizer, do not let Single Super Phosphate directly contact the seeds, and can be properly mixed with some organic fertilizer to reduce the damage to the seeds.

The Single Super Phosphate Production Line is a critical asset in the agricultural industry, providing an essential nutrient that supports crop growth and soil fertility. By efficiently producing SSP, these production lines contribute to global food security and the sustainable development of agriculture.

Send a message to us