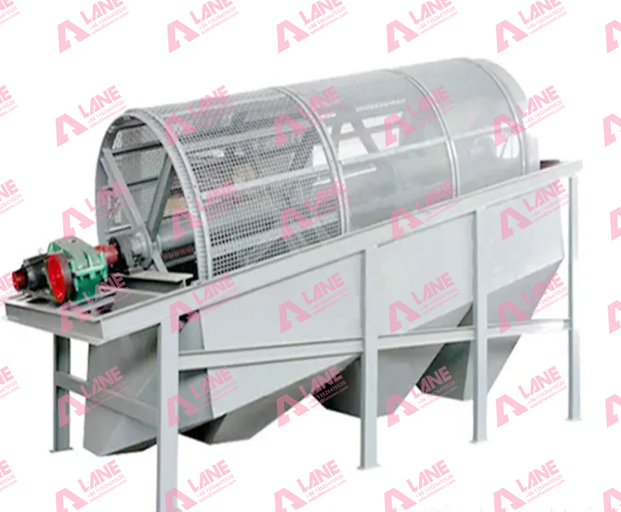

Rotary Screen Machine

In the world of fertilizer production, precision and quality control are paramount. One essential piece of equipment that plays a vital role in ensuring these factors is the Rotary Screen Machine. LANE Group’s Rotary Screen Machine is designed to efficiently separate and grade different particles, ensuring that only the best quality fertilizer products reach the market. This machine is a cornerstone of any fertilizer production line, contributing to consistent product quality and optimized production processes.

A Rotary Screen Machine, also known as a rotary screener or drum screen, is a mechanical device used to separate materials based on particle size. In fertilizer production, it is commonly used to screen and grade granular fertilizers, ensuring that only particles of the desired size pass through, while larger or smaller particles are either reprocessed or discarded.

Key Features

LANE Rotary Screen Machine is engineered with advanced features that make it a reliable and efficient tool for fertilizer production:

- High Screening Efficiency: The rotary drum design of the screen machine allows for continuous and uniform screening of materials. The rotating motion ensures that all particles are exposed to the screening surface, maximizing efficiency and accuracy in separating different particle sizes.

- Durable Construction: Built with high-quality materials, the Rotary Screen Machine is designed to withstand the harsh conditions of fertilizer production, including exposure to abrasive materials and constant operation. Its robust construction ensures long-term durability and reliability.

- Customizable Mesh Sizes: The screen machine can be equipped with different mesh sizes to suit various screening requirements. This flexibility allows producers to customize the screening process based on the specific needs of their fertilizer products.

- Low Noise and Vibration: The Rotary Screen Machine operates with minimal noise and vibration, providing a more comfortable and safer working environment. This feature also helps extend the life of the machine by reducing wear and tear on its components.

- Easy Maintenance: The machine is designed for easy access to all components, making cleaning, inspection, and maintenance straightforward and efficient. This reduces downtime and ensures that the production line remains operational with minimal interruptions.

- Energy Efficiency: LANE Group’s Rotary Screen Machine is engineered to be energy-efficient, reducing power consumption without compromising performance. This not only lowers operational costs but also supports sustainable production practices.

Pictures of Equipment

Application

The Rotary Screen Machine is versatile and can be used in various stages of fertilizer production:

- Granular Fertilizer Screening: The machine is ideal for screening granular fertilizers, ensuring that only particles within a specific size range are allowed to proceed to the next stage of production. This helps in producing a consistent and uniform product that meets market standards.

- Organic Fertilizer Production: In organic fertilizer production, the Rotary Screen Machine is used to screen composted materials and other organic matter, ensuring that the final product is free from oversized particles or impurities.

- Compound Fertilizer Production: The machine is also used in the production of compound fertilizers to separate different granular sizes, ensuring that the final blend is uniform and meets the desired nutrient composition.

- Waste Management: Beyond fertilizer production, the Rotary Screen Machine can be used in waste management processes to separate recyclable materials from waste, contributing to more efficient recycling operations.

Benefit

- Consistent Product Quality: The machine’s high screening efficiency ensures that only particles of the desired size make it through to the final product. This consistency is key to producing high-quality fertilizers that meet industry standards and customer expectations.

- Optimized Production Processes: By efficiently separating materials based on size, the Rotary Screen Machine helps streamline production processes, reducing the need for reprocessing and minimizing waste. This leads to more efficient use of resources and higher overall productivity.

- Reduced Operational Costs: The machine’s energy-efficient design and low maintenance requirements help reduce operational costs, making it a cost-effective investment for fertilizer producers.

- Versatility in Application: The Rotary Screen Machine’s ability to handle different materials and particle sizes makes it a versatile tool that can be used in various production settings, from organic to compound fertilizers.

About LANE

Delivery site

Our Clients from All Over the World