Rotary Drum Granulator: High-Capacity NPK Fertilizer Production with 90%+ Balling Rate

For fertilizer manufacturers targeting large-scale production of NPK, DAP, MAP, and other compound fertilizers, achieving consistent high output and superior granule quality is critical. The Rotary Drum Granulator is the industry-preferred solution, engineered to transform powder blends into uniform, spherical granules through an efficient steam-assisted wet granulation process. Capable of handling capacities from 2 to over 20 tons per hour with a balling rate exceeding 90%, this robust machine forms the reliable core of modern high-volume fertilizer plants. Henan Lane Heavy Industry designs and delivers heavy-duty rotary drum granulators, integrating process expertise to maximize your plant’s efficiency and profitability.This efficient production of balanced fertilizers supports global goals for sustainable crop nutrition and soil health.

What is a Rotary Drum Granulator?

A Rotary Drum Granulator is a central piece of equipment in wet process fertilizer production lines. The Rotary Drum Granulator consists of a large, slightly inclined cylindrical drum that rotates on its axis. Raw material powders are fed continuously into the elevated end. Inside the rotating drum, the tumbling motion of the material, combined with the introduction of a liquid binder (typically water and steam), causes fine particles to coalesce and grow into dense, spherical granules through a layering mechanism. It is renowned for its high capacity, reliability, and ability to produce premium-quality fertilizer pellets.

How Does the Steam Granulation Process Work?

Feeding & Homogenization: Pre-mixed raw materials enter the rotating drum. The rotation ensures continuous and thorough blending.

Steam Injection & Nucleation: Controlled steam is introduced, raising the temperature of the material mass. This creates a thin, uniform liquid phase on particle surfaces, dramatically improving granulation efficiency and reducing the need for cold water.

Agglomeration & Growth: The cascading and tumbling action inside the drum causes the moistened fine particles to collide and stick together, forming seed pellets. These seeds grow larger as more material layers onto them.

Spheronization & Discharge: The continuous rotation polishes the granules, enhancing their roundness and strength. Finished granules exit at the lower end of the inclined drum, ready for drying, cooling, and screening in the complete fertilizer production line.

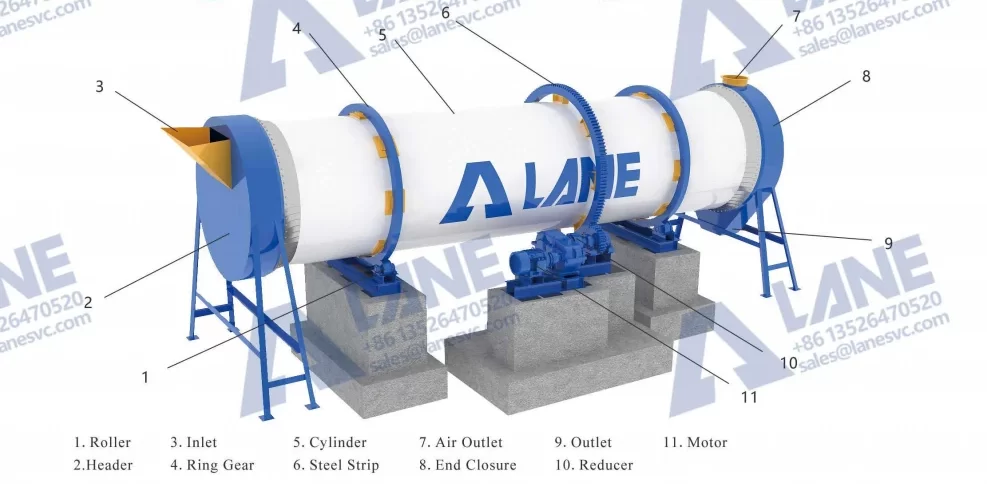

In-Depth Analysis: Key Components and Their Role in Efficiency

Understanding the critical components explains the durability and performance:

Drum Shell: The main cylinder, often lined with durable rubber or special steel to prevent corrosion and adhesion, providing the space for granulation.

Internal Lifters/Flights: These plates are mounted inside the drum. Their primary function is to lift the material to a certain height as the drum rotates, creating the optimal cascading curtain for uniform mixing and granule growth.

Support System (Trunnion Rollers & Thrust Rollers): Heavy-duty rollers support the entire weight of the drum and material, ensuring smooth, stable rotation with minimal friction.

Drive Unit (Gear Ring & Pinion): A large gear ring attached to the Rotary Drum Granulator is driven by a motorized pinion, providing the powerful torque needed for rotation.

Inlet & Outlet Seals: Specialized sealing systems at both ends prevent dust and steam leakage, maintaining a clean operating environment and process efficiency.

Key Advantages of Rotary Drum Granulation Technology

Exceptional Capacity & Scalability: Designed for continuous 24/7 operation, with models available to match outputs from 2 to over 20 T/H, making it ideal for large-scale NPK fertilizer production.

High Granulation Efficiency: Achieves a balling rate of over 90%, minimizing raw material waste and recycling of fines, which translates directly to higher yield and lower cost per ton.

Superior Granule Quality: Produces strong, spherical, and uniformly-sized granules with excellent flow characteristics, ideal for subsequent coating, bulk storage, and precise mechanical application.

Steam Optimization: The use of steam as a binder allows for lower overall moisture content in the granules, which significantly reduces the energy burden on the downstream drying equipment.

Process Flexibility & Robustness: Well-suited for a wide range of formulations and raw material characteristics (including certain organic fractions), and built with durable materials to withstand corrosive environments.

Primary Applications: The Heart of Major Fertilizer Plants

This granulator is the definitive choice for:

Large-scale NPK Compound Fertilizer Production Lines

DAP (Diammonium Phosphate) and MAP (Monoammonium Phosphate) Plants

Organic-Mineral Compound Fertilizer Granulation

Other Industrial Agglomeration Processes requiring high-volume output.

Henan Lane‘s Engineering & Service Commitment

We provide more than a Rotary Drum Granulator; we deliver a performance-guaranteed granulation solution. Our Rotary Drum Granulator feature wear-resistant linings, optimally designed internal lifters for efficient material movement, and heavy-duty drive systems. Supported by comprehensive process design and global project management experience, we ensure your equipment integrates seamlessly and operates at peak performance.

Why Choose Henan Lane as Your Partner?

Proven Global Expertise: Our granulators are operational in fertilizer plants across 120+ countries, from Southeast Asia to Africa and the Americas.

End-to-End Project Support: From initial free granulation testing with your formula to detailed engineering, installation, commissioning, and operator training.

Custom-Engineered Solutions: We design and manufacture to match your exact capacity, raw material, and site-specific requirements, ensuring optimal investment efficiency.

Ready to Build or Upgrade Your High-Capacity Fertilizer Line?

If your goal is to establish a new plant or enhance the productivity of an existing facility with reliable, high-output technology, the Rotary Drum Granulator is the proven industrial standard.

Contact Henan Lane Heavy Industry today to discuss your project specifications, request a free process review and granulation test, or receive a detailed technical proposal.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Send a message to us