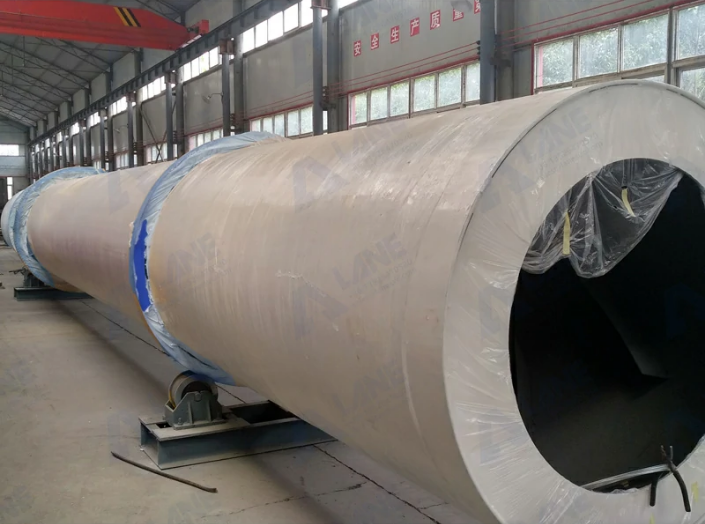

Rotary Drum Granulator

A rotary drum granulator is a type of granulation equipment that uses a rotating drum to form raw materials into uniform granules. The drum is inclined at a slight angle, allowing materials to tumble and roll as the drum rotates. Through a combination of rolling, impact, and centrifugal force, the materials coalesce into granules. This granulation method is particularly effective for producing compound fertilizers, such as NPK fertilizers, where the consistent mixing and binding of ingredients are essential.

The rotary drum granulator is valued for its versatility, capable of processing a wide range of materials, including organic and inorganic substances. Its ability to handle high moisture content materials and create granules of various sizes makes it a highly flexible tool in fertilizer production.

LANE Group’s Rotary Drum Granulator is engineered to optimize the granulation process, ensuring high efficiency and consistent product quality:

- Raw Material Feeding: The process begins with the feeding of raw materials into the granulator. These materials can include powdered fertilizers, minerals, and additives that need to be granulated.

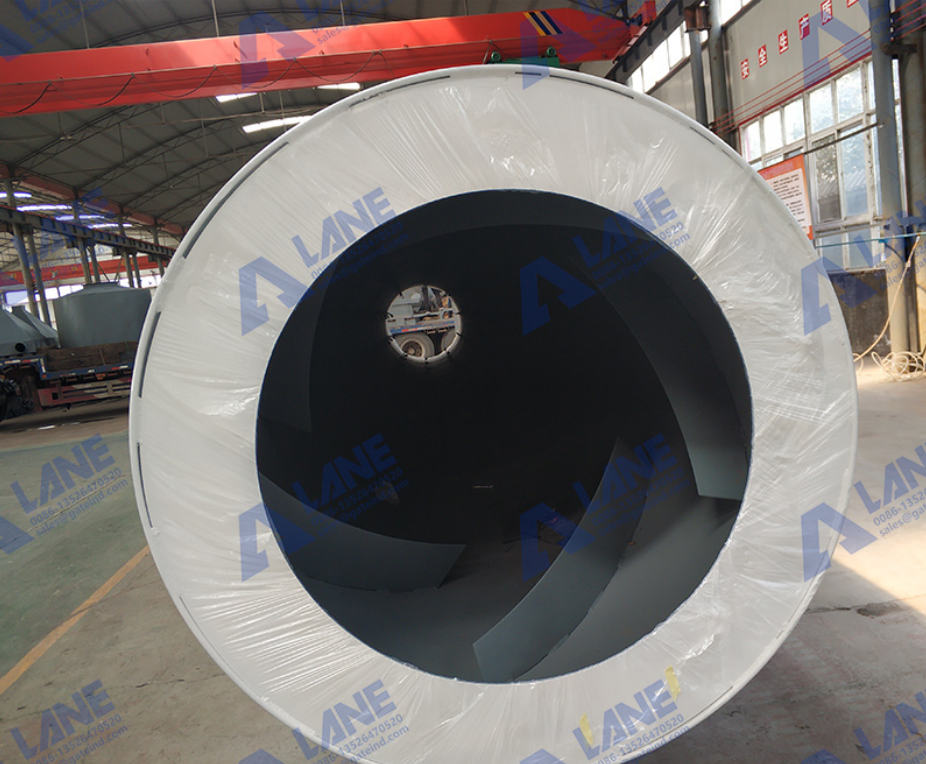

- Drum Rotation and Granulation: As the drum rotates, the materials are lifted and dropped repeatedly, causing them to tumble and roll within the drum. This motion, combined with the impact and centrifugal forces, causes the particles to coalesce into granules.

- Binding and Coating: During the granulation process, a liquid binder or coating agent may be sprayed onto the material to enhance the binding of particles and improve granule hardness. This step also helps to control dust and improve the durability of the granules.

- Granule Formation: As the materials continue to roll and mix inside the drum, they gradually form into spherical granules. The size of the granules can be controlled by adjusting the speed of the drum rotation and the amount of binder applied.

Advantage

- The ball forming rate is above 90%, with a small amount of regrind, and the granularity of regrind is small.

- Steam can be introduced to increase the temperature of the material, so that the moisture content of the material after balling is low, and the drying efficiency is improved.

- Use rubber lining or acid-resistant stainless steel lining, anti-corrosion and heat preservation, not easy to stick to the cylinder.

- Large output, low energy consumption, simple operation and low maintenance cost.

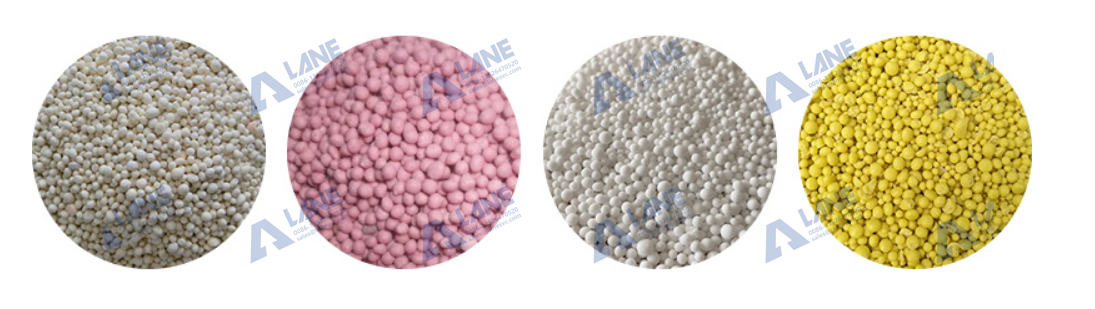

Finished Product Display

Applications of the Rotary Drum Granulator

The Rotary Drum Granulator is widely used in the production of various types of fertilizers, making it a versatile tool in the agricultural industry:

- NPK Fertilizers: The granulator is ideal for producing NPK fertilizers, which are essential for balanced plant nutrition, offering a controlled release of nutrients.

- Organic Fertilizers: For organic fertilizers, the granulator can process organic materials such as compost and manure, converting them into high-quality granules.

- Compound Fertilizers: The granulator is perfect for producing compound fertilizers that combine multiple nutrients in a single granule, providing comprehensive nutrition for crops.

- Bio Fertilizers: The granulator can be used to produce bio fertilizers that incorporate living microorganisms, ensuring their viability and effectiveness in the soil.

Our Service

Latest Articles & Tips

More-

01/14

read more -

12/02

Triple Superphosphate and DAP: Which Fertilizer is Best for Your Crops?

read more -

09/30

Revolutionizing Crop Production: The DAP Agri Fertilizer Production Line Explained

read more -

02/27

Fertilizer Production Solutions: Optimizing Efficiency and Sustainability in Fertilizer Manufacturing

read more