Rotary Drum Dryer

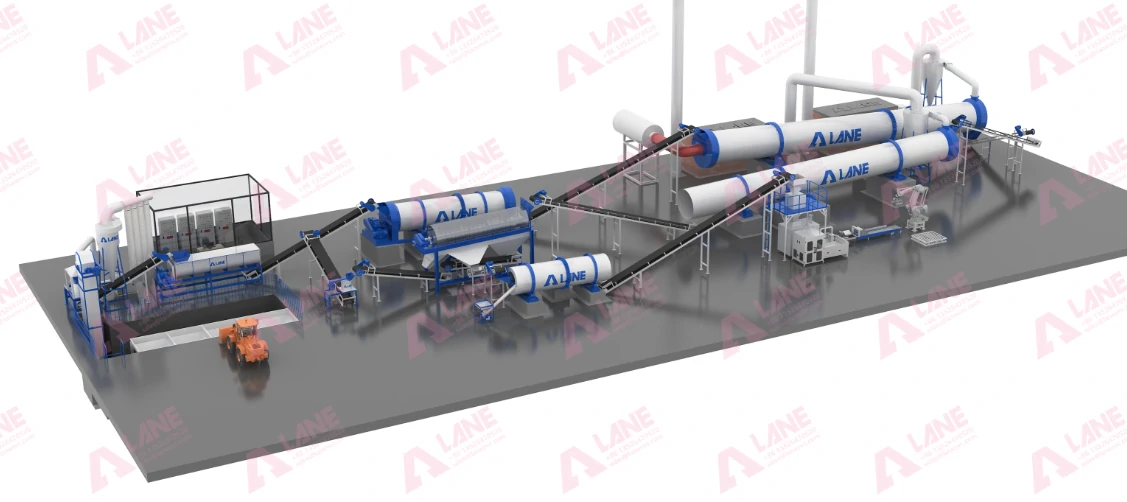

Drum dryer is a kind of drying equipment commonly used in fertilizer production line. Rotary drum dryer consists of drum, feeding device,discharging device,transmission device, hot gas system and electrical control system. Its working principle is that the high humidity fertilizer raw materials through the feeding device into the drum, drying process in the drum. The drum is a large, cylindrical tube that rotates on its axis, allowing materials to tumble and mix as they are exposed to heat. This method ensures even drying and prevents clumping or uneven moisture distribution in the final product.

The Rotary Drum Dryer is particularly effective for drying large volumes of material with high moisture content, making it ideal for use in fertilizer production. It is designed to handle a variety of materials, including organic matter, mineral fertilizers, and chemical compounds, ensuring versatility across different production lines.

The Drying Process in LANE Group’s Rotary Drum Dryer

LANE Group’s Rotary Drum Dryer is engineered to optimize the drying process, ensuring maximum efficiency and consistent product quality:

- Material Feeding: The process begins with the feeding of wet or moist materials into the rotary drum. The materials can include organic compost, manure, chemical fertilizers, or other bulk materials that require drying.

- Drum Rotation and Heat Exchange: As the drum rotates, the materials are lifted and dropped by the internal flights (lifting plates) inside the drum. This motion causes the materials to tumble and mix, ensuring even exposure to the heat source. Depending on the design, the dryer can use direct or indirect heating methods, where hot air or flue gases pass through the drum or are conducted through an external shell.

- Moisture Evaporation: The heat applied to the material causes moisture to evaporate. The combination of tumbling and mixing ensures that the drying is uniform, preventing hotspots or overly dried sections. The moisture-laden air is then vented out of the drum, and the drying process continues until the desired moisture level is achieved.

- Discharge and Cooling: Once the materials reach the appropriate moisture content, they are discharged from the drum for further processing or packaging. In some cases, the dried materials may be cooled using a separate cooling system to stabilize the product and prevent any post-drying moisture absorption.

Advantages

LANE Rotary Drum Dryer offers several key advantages that make it an excellent choice for fertilizer production:

- High Drying Efficiency: The rotary drum design ensures that materials are evenly dried, with minimal heat loss, resulting in a highly efficient drying process that reduces energy consumption.

- Versatility: The dryer can handle a wide range of materials, including organic and inorganic substances, making it suitable for various types of fertilizers and other bulk products.

- Consistent Product Quality: The even drying process ensures that the final product has a uniform moisture content, which is critical for maintaining product quality and stability.

- Durable Construction: LANE Group’s Rotary Drum Dryer is built with high-quality materials and components, ensuring long-term durability and reliable performance in demanding production environments.

- Energy Efficiency: The dryer is designed to optimize heat transfer and reduce energy consumption, lowering operational costs and minimizing environmental impact.

Applications of the Rotary Drum Dryer

The Rotary Drum Dryer is widely used in the production of various types of fertilizers and other bulk materials, making it a versatile tool in the agricultural and industrial sectors:

- Organic Fertilizers: The dryer is ideal for drying organic compost, manure, and other organic materials, converting them into stable, high-quality granules or powders.

- Inorganic Fertilizers: The dryer can efficiently handle mineral-based fertilizers, such as phosphate and potash, ensuring they are dried to the correct moisture content for storage and application.

- Compound Fertilizers: The dryer is perfect for drying compound fertilizers that combine multiple nutrients, ensuring that the final product is free of moisture-related issues.

- Bio-Fertilizers: The dryer can be used to process bio-fertilizers, which require precise moisture control to maintain the viability of living microorganisms.

Latest Articles & Tips

More-

09/10

read moreLANE Group Completes Shipment of State-of-the-Art Di-Ammonium Phosphate Production Lines

-

01/21

read more -

03/14

OEM Fertilizer Equipment Manufacturing: Custom Solutions for Your Production Needs

read more -

01/22

DAP Fertilizer Granulation Plant Design: Key Considerations for Maximum Efficiency

read more