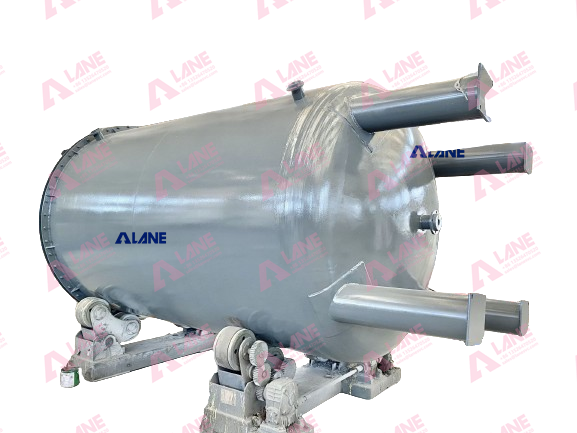

Reaction Kettle

In the production of phosphate fertilizers, the reaction between sulfuric acid and phosphate rock powder is a critical process. This reaction produces phosphoric acid, a key ingredient in the manufacture of various phosphate-based fertilizers. To achieve optimal efficiency and safety in this process, a high-quality reaction kettle is essential. LANE Group’s Reaction Kettle for Sulfuric Acid and Phosphate Rock Reactions is designed to handle this demanding process, ensuring precise control, safety, and high productivity.

The reaction between sulfuric acid and phosphate rock powder is exothermic, releasing a significant amount of heat. This reaction must be carefully managed to prevent overheating, ensure complete conversion of reactants, and produce high-purity phosphoric acid. The reaction kettle plays a central role in this process by providing a controlled environment where the reaction can take place efficiently and safely.

LANE Group’s Reaction Kettle is specifically engineered for this application, offering advanced features that enhance the performance and reliability of the phosphate fertilizer production process.

Key Features

LANE Group’s Reaction Kettle for sulfuric acid and phosphate rock reactions is designed with cutting-edge technology and high-quality materials to meet the rigorous demands of the fertilizer industry. Here are some of the key features:

- Corrosion-Resistant Construction: The reaction kettle is constructed from materials that are highly resistant to corrosion, such as stainless steel or lined with protective coatings. This ensures long-term durability and prevents the aggressive sulfuric acid from damaging the vessel.

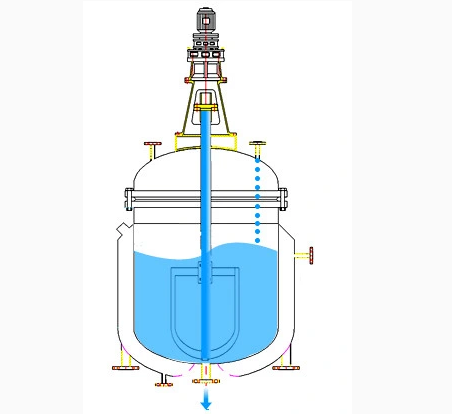

- Efficient Mixing and Agitation: The kettle is equipped with a powerful agitation system that ensures thorough mixing of the sulfuric acid and phosphate rock powder. This promotes a uniform reaction, maximizing the yield of phosphoric acid and reducing the formation of by-products.

- Temperature Control: To manage the exothermic nature of the reaction, the reaction kettle is fitted with an advanced temperature control system. This system monitors the temperature in real-time and adjusts the cooling or heating mechanisms to maintain optimal reaction conditions.

- Pressure Management: The reaction between sulfuric acid and phosphate rock can generate gases, requiring the kettle to be designed to handle fluctuations in pressure. LANE Group’s reaction kettle includes pressure relief systems and vents to safely manage any pressure buildup.

- Safety Features: Safety is a top priority in the design of LANE Group’s Reaction Kettle. The kettle includes features such as emergency shutdown systems, alarms, and safety valves to protect operators and equipment from potential hazards.

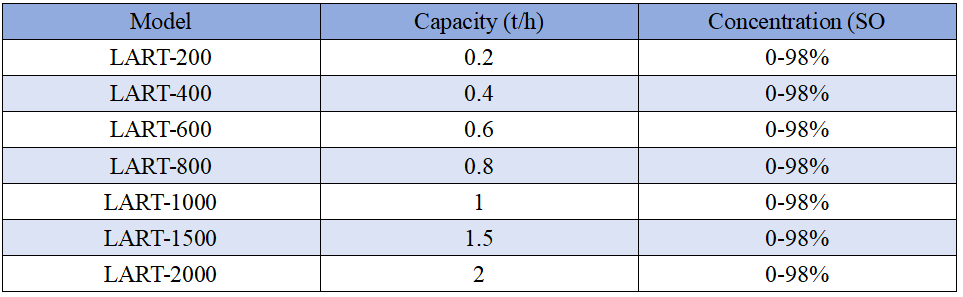

- Scalable Design: Whether for a small-scale operation or large industrial production, LANE Group offers reaction kettles in various sizes and configurations. This scalability allows manufacturers to choose a kettle that fits their production needs while maintaining efficiency and safety.

The Reaction Process: Sulfuric Acid and Phosphate Rock Powder

The reaction process involves the careful combination of sulfuric acid and finely ground phosphate rock powder. Here’s a step-by-step overview of how the process is carried out in LANE Group’s Reaction Kettle:

- Loading

- Mixing and Agitation

- Reaction Monitoring

- Phosphoric Acid Formation

- Discharge

If you want to know the details, Send us your inquiry!

Application

LANE Group’s Reaction Kettle is primarily used in the production of phosphoric acid, a precursor for various phosphate fertilizers. Here are some of the key applications:

- Phosphate Fertilizers: The phosphoric acid produced in the reaction kettle is a key ingredient in the manufacture of phosphate fertilizers such as triple superphosphate (TSP) and monoammonium phosphate (MAP). These fertilizers are essential for providing plants with the phosphorus they need for healthy growth.

- Chemical Manufacturing: Beyond fertilizers, phosphoric acid is used in the production of various chemicals, including detergents, food additives, and industrial cleaners. The reaction kettle ensures the efficient production of high-purity phosphoric acid for these applications.

- Mineral Processing: In the mining industry, the reaction kettle is used in the processing of phosphate ores, converting them into valuable chemical products.

Advantage

When you choose LANE Group’s Reaction Kettle for sulfuric acid and phosphate rock reactions, you benefit from several key advantages:

- Enhanced Efficiency: The advanced mixing, temperature control, and pressure management systems ensure that the reaction is carried out efficiently, maximizing the yield of phosphoric acid and minimizing waste.

- Safety and Reliability: LANE Group’s commitment to safety is reflected in the robust design and comprehensive safety features of the reaction kettle, providing peace of mind in demanding industrial environments.

- Customization: LANE Group offers tailored solutions to meet the specific needs of your production process, from the choice of materials to the size and configuration of the reaction kettle.

- Expert Support: LANE Group provides expert support throughout the installation, operation, and maintenance of the reaction kettle, ensuring that your production process runs smoothly and efficiently.