Potassium Sulfate Manufacturing Plant: Practical Guide to SOP Fertilizer Production

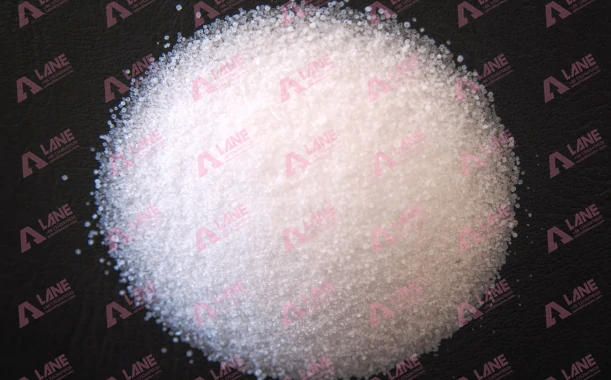

A potassium sulfate manufacturing plant is designed to produce sulfate of potash (SOP), a chlorine-free potassium fertilizer widely used for high-value crops. SOP is preferred for crops sensitive to chloride, such as fruits, vegetables, tobacco, and potatoes.

From an industrial perspective, SOP production requires precise process control and reliable equipment. Compared with potassium chloride-based fertilizers, SOP manufacturing involves more complex reactions and higher technical requirements. A well-designed potassium sulfate manufacturing plant focuses on stable output and consistent product quality.

What Is a Potassium Sulfate Manufacturing Plant?

A potassium sulfate manufacturing plant is an industrial system that converts potassium-containing raw materials into sulfate of potash fertilizer. The most common production routes include the Mannheim process and other chemical conversion methods.

In fertilizer plants, SOP production is often positioned as a specialty fertilizer line. This allows manufacturers to serve premium agricultural markets while maintaining flexibility in production planning.

Why Potassium Sulfate Is Important in Modern Agriculture

Potassium sulfate provides two essential nutrients: potassium and sulfur. Unlike potassium chloride, it does not introduce chloride ions into the soil.

Key advantages of SOP fertilizer include:

Suitable for chloride-sensitive crops

Improves crop quality and yield

Supplies sulfur nutrition

Compatible with intensive farming systems

These agronomic benefits drive demand for reliable potassium sulfate manufacturing plants worldwide.

Potassium Sulfate Production Process Explained

Raw Material Preparation

Production begins with potassium chloride or other potassium-bearing materials, depending on the chosen process. Raw materials must meet purity and particle size requirements to ensure reaction efficiency.

Inconsistent raw material quality often leads to unstable SOP output.

Chemical reaction stage:

In the Mannheim process, potassium chloride reacts with sulfuric acid at a high temperature. This reaction produces potassium sulphate and releases hydrogen chloride gas as a by-product.

The reaction temperature and residence time are critical. Incomplete conversion or excessive equipment wear can result from poor control.

Cooling and solidification:

After the reaction, the molten or semi-molten material is cooled. Controlled cooling helps to form stable SOP crystals and improves downstream handling.

The efficiency of cooling directly affects product structure and storage behavior.

Crushing and screening:

Solidified SOP is crushed and screened to achieve the desired particle size. Oversized particles are recycled, while fines may be reprocessed or blended.

A uniform particle size improves the performance of the fertilizer application.

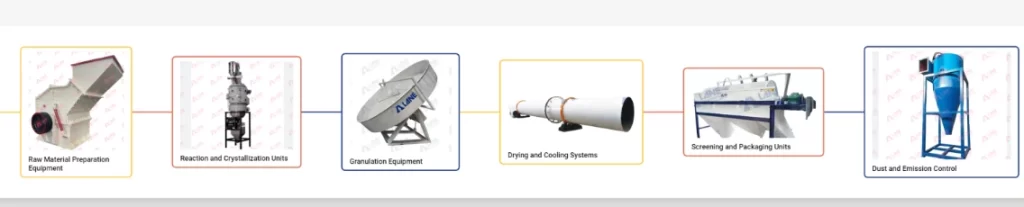

Key Equipment in the Production Process of Potassium Sulfate Manufacturing Plant

- Raw Material Preparation Equipment

- Crushers: Used to grind raw materials like potassium chloride into fine particles.

- Mixers: Ensure a uniform mixture of raw materials before the chemical reaction.

- Reaction and Crystallization Units

- Reactors: Where the chemical reaction between potassium chloride and sulfuric acid occurs to produce potassium sulfate.

- Crystallizers: Facilitate the formation of potassium sulfate crystals from the reaction mixture.

- Granulation Equipment

- Rotary Drum Granulator: Granulates the crystallized potassium sulfate into uniform-sized granules suitable for agricultural use.

- Disc Granulator: An alternative granulation method that offers flexibility in adjusting granule size.

- Drying and Cooling Systems

- Rotary Dryer: Removes excess moisture from the granules, enhancing their storage and transport stability.

- Rotary Cooler: Cools the dried granules to the desired temperature, preventing clumping during packaging.

- Screening and Packaging Units

- Rotary Screen Machine: Screens the granules to separate fine particles and oversized granules, ensuring uniformity in the final product.

- Automatic Packing Machine: Packages the screened granules into bags for distribution, ensuring accuracy and efficiency.

- Dust and Emission Control

- Cyclone Dust Collectors: Capture dust generated during the crushing, drying, and granulation processes, maintaining a clean production environment.

- Scrubbers: Remove harmful gases and particulates from the exhaust, ensuring compliance with environmental regulations.

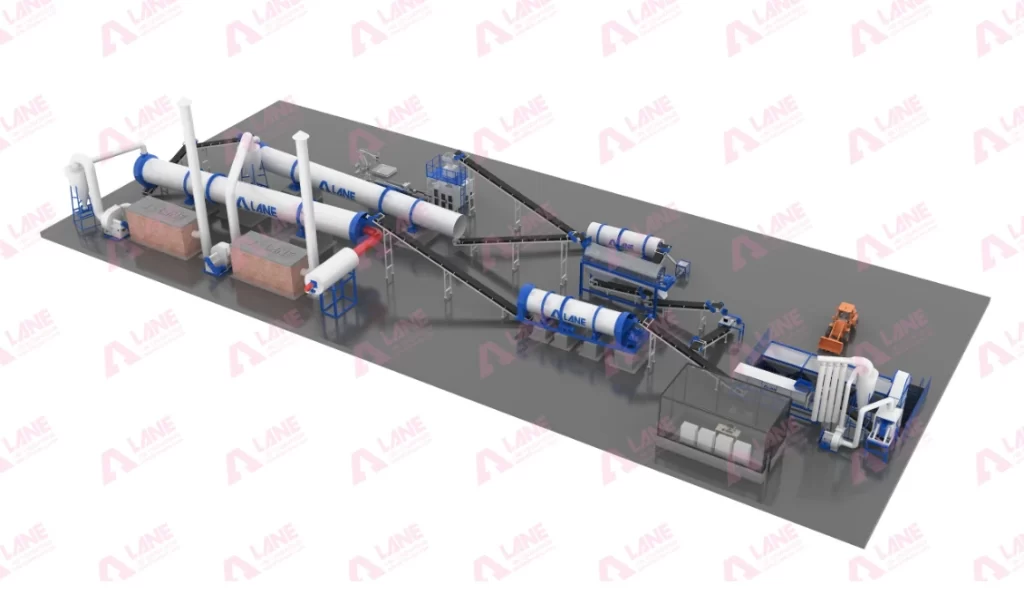

Key Features of the Sulphate of Potash Production Line

Optimized Production Process:The SOP production line is engineered to maximize efficiency, ensuring high output with minimal waste. This optimization results in a more cost-effective production process, allowing manufacturers to produce large quantities of SOP at a lower cost.

Advanced Technology Integration:Cutting-edge technology is integrated throughout the production line, from raw material processing to final product packaging. Automated systems enhance precision and reduce human error, leading to a more consistent and reliable product.

Customizable Output:The production line can be tailored to produce SOP in various forms, such as granules, powder, or crystals, depending on market requirements. This flexibility allows manufacturers to meet the specific needs of different agricultural sectors.

Environmental Sustainability:The production line is designed with environmental considerations in mind. Efficient waste management and emission control systems are implemented to minimize the environmental impact, making the production process more sustainable.

Quality Control in SOP Fertilizer Production

Product quality in a potassium sulfate manufacturing plant depends on several operational factors:

Raw material purity

Reaction temperature stability

Residence time control

Cooling rate

Particle size distribution

Consistent monitoring helps maintain SOP nutrient content and physical stability.

Environmental and Safety Considerations

Potassium sulfate production involves high-temperature reactions and acidic byproducts. Environmental protection and safety management are therefore essential.

Typical measures include gas absorption systems for hydrogen chloride, dust collection units, and proper ventilation. Operator training and safety procedures reduce operational risks.

Integration with Compound Fertilizer Plants

A potassium sulfate manufacturing plant can be integrated with compound fertilizer or blending lines. SOP serves as a high-quality potassium source for specialty NPK formulations.

This integration improves raw material utilization and expands product portfolios without major infrastructure changes.

Operational Challenges and Maintenance

Common operational challenges include reactor lining wear, acid corrosion, and gas handling efficiency. Regular inspection and preventive maintenance help reduce downtime.

Stable operation depends more on process discipline than frequent parameter changes.

Choosing the Right Potassium Sulfate Manufacturing Plant Supplier

When selecting a potassium sulfate manufacturing plant supplier, manufacturers should evaluate practical project experience, equipment durability, and technical support capability.

A reliable supplier should provide:

Process design based on raw materials

Durable, corrosion-resistant equipment

Installation and commissioning support

Long-term technical service

These factors strongly influence startup success and operating stability.

Conclusion

For internationally recognized fertilizer definitions and quality benchmarks, manufacturers can refer to the FAO fertilizer specifications for potassium sulfate, which provide standardized classifications and technical references for SOP and other straight fertilizer.

A potassium sulfate manufacturing plant is a key asset for producing high-quality SOP fertilizer. With proper process design, stable operation, and suitable equipment selection, manufacturers can achieve consistent output and meet the demands of high-value crop markets.

Call to Action

If you are planning to build or upgrade a potassium sulfate manufacturing plant, early technical evaluation can help reduce risks and optimize investment. Professional process design and equipment support ensure stable SOP production and long-term plant performance.

Ready to choose the right fertilizer production solution? Contact LANE today to learn more about .

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Send a message to us