The Science Behind Phosphate Production Lines: Driving Efficiency and Growth

The Core Science of Phosphate Production Line

Phosphate production begins with the extraction of phosphate rock, a naturally occurring mineral found in sedimentary deposits. This raw material contains phosphorus, an essential element for plant growth. Once extracted, phosphate rock undergoes several stages of chemical and physical treatments, transforming it into fertilizers like phosphoric acid or phosphate-based compounds. These are then used in the agricultural sector to enrich the soil and promote better crop yields.

At the heart of phosphate production line is the chemical reaction involving sulfuric acid and phosphate rock. This process produces phosphoric acid, the main ingredient in many phosphate fertilizers. In more advanced production lines, continuous-flow reactors, high-efficiency pumps, and real-time monitoring systems optimize this reaction, ensuring that the conversion from phosphate rock to phosphoric acid is as efficient as possible.

The efficiency of this process is driven by precise control over factors like temperature, pressure, and acid concentration. Modern production lines integrate advanced sensor systems and automated controls to ensure that the reactions occur under optimal conditions, reducing waste and increasing the overall yield of usable fertilizer.

Innovations in Technology Enhancing Efficiency

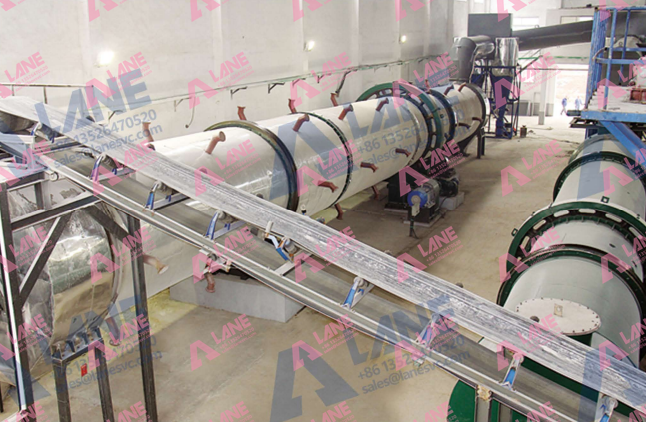

The role of automation in phosphate production line cannot be overstated. Modern technology allows for complete automation of many stages in the process, from the grinding of phosphate rock to the chemical treatment phase and final packaging. Automated systems increase precision, reduce human error, and improve the speed and consistency of production.

For example, digital control systems monitor the chemical reactions in real-time, adjusting the inputs of sulfuric acid and other reagents as necessary to maintain peak efficiency. Automated material handling systems streamline the movement of phosphate rock through various stages of crushing, mixing, and chemical treatment, ensuring that the production line operates continuously without unnecessary downtime.

Moreover, computer-based models allow for predictive maintenance. By collecting data from the equipment in use, the system can predict when a machine will need servicing, reducing the likelihood of unexpected breakdowns and improving overall production uptime. These advancements in technology have resulted in a significant reduction in labor costs and an increase in production speed and reliability.

Environmental Sustainability in Phosphate Production Line

Environmental concerns have also become a key focus for modern phosphate production line. The chemical reactions involved in phosphate production can generate waste materials and emissions, such as phosphogypsum and sulfur dioxide (SO2). To mitigate these environmental impacts, many production lines now integrate technologies for waste recycling and emissions control.

One approach is the use of waste heat recovery systems, which capture and repurpose heat generated during the production process. This energy can be redirected to power other parts of the facility, reducing the overall energy footprint of the plant. Furthermore, the use of scrubbers helps capture sulfur dioxide emissions, converting them into useful byproducts or safely neutralizing them before release into the atmosphere.

Sustainable water management is another critical area. Phosphate production requires significant volumes of water for cooling and processing, but by using closed-loop water recycling systems, modern production lines minimize water waste. These systems filter and treat used water, allowing it to be reused in the production process and reducing the plant’s overall water consumption.

Incorporating sustainability into phosphate production line not only helps reduce environmental impact but also creates long-term cost savings. With growing pressure from governments and environmental agencies, sustainable production practices are becoming a vital part of the fertilizer manufacturing industry.

Enhancing Yield and Production Capacity

A key goal for any phosphate production line is to maximize yield while maintaining product quality. Recent innovations in production line technology, including continuous-flow reactors and high-pressure processing units, have made it possible to significantly increase the capacity of phosphate production plants.

Continuous-flow reactors allow for uninterrupted production, reducing downtime and enabling higher volumes of phosphoric acid to be produced in a shorter timeframe. This technology ensures that phosphate rock is continuously fed into the reaction chamber, where sulfuric acid is added to produce phosphoric acid. By maintaining a constant flow, production lines can operate more efficiently and achieve higher outputs.

Advanced grinding technologies also contribute to improved efficiency. The finer the phosphate rock is ground, the more surface area is exposed to the chemical reaction, resulting in a higher yield of phosphoric acid. Innovations such as high-pressure grinding rolls (HPGR) and vertical roller mills have enabled phosphate production plants to achieve better grinding performance with less energy, reducing costs while increasing output.

Additionally, optimizing the ratio of phosphate rock to sulfuric acid is essential for increasing production efficiency. Advances in monitoring and process control systems allow for more accurate dosing of these key ingredients, ensuring that the reaction proceeds efficiently and with minimal waste. These improvements have helped increase the overall yield of usable phosphate fertilizer while reducing the need for excess raw materials.

Economic and Global Implications of Phosphate Production

As the global population continues to grow, the demand for phosphate-based fertilizers is expected to increase. This puts pressure on fertilizer manufacturers to improve their production capabilities and reduce costs while maintaining high-quality products. Phosphate production line play a pivotal role in meeting this global demand by enabling manufacturers to scale up production efficiently.

Moreover, advancements in production technology have made it possible to build phosphate plants in regions where they were previously unfeasible. The increased efficiency of modern production lines means that smaller, regional plants can now compete with larger facilities, helping to decentralize phosphate fertilizer production and make it more accessible to different parts of the world.

In the long term, the ongoing development of more efficient and environmentally friendly phosphate production line will help stabilize global fertilizer markets, ensuring that agricultural producers can meet the food needs of a growing global population. By improving efficiency and reducing environmental impact, phosphate production lines are set to become even more critical to the future of global agriculture.

Conclusion

Phosphate production line represent the cutting edge of fertilizer manufacturing, combining scientific innovation, advanced technology, and sustainable practices. By optimizing chemical reactions, automating processes, and implementing environmentally responsible solutions, these production lines are driving efficiency and growth in the global fertilizer industry. As the world continues to face increasing agricultural demands, phosphate production lines will play a vital role in ensuring a steady, sustainable supply of essential nutrients for crops, supporting global food security and agricultural sustainability.

Send a message to us