NPK Manufacturing Plant: Complete Guide to Efficient Compound Fertilizer Production

An NPK Manufacturing plant stands at the heart of modern compound fertilizer manufacturing. As agriculture evolves towards greater efficiency and balanced nutrition, fertilizer producers require systems capable of handling diverse raw materials, flexible formulations, and stable long-term operation. A well-designed NPK Manufacturing plant enables manufacturers to produce uniform granules while controlling production costs and quality.

Today’s fertilizer plants focus not only on output but also on adapting to shifting market demands and diverse raw materials. A reliable NPK fertilizer plant must maintain consistent performance under actual production conditions.

What Is an NPK Manufacturing Plant?

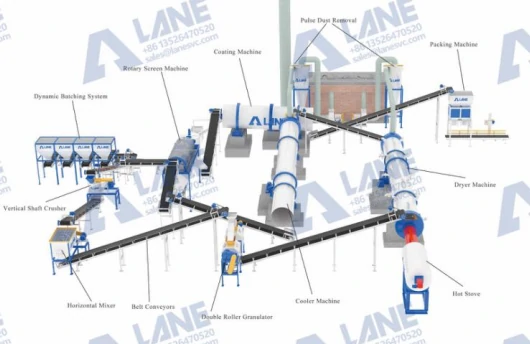

LANE NPK manufacturing plant for compound fertilizer production

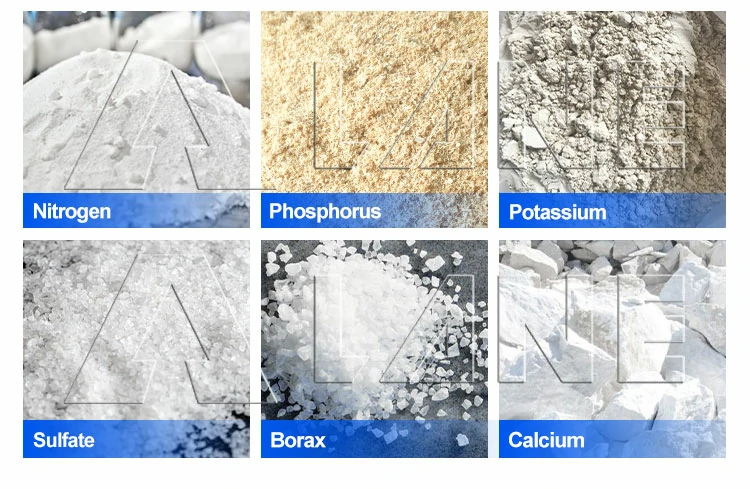

In practical terms, an NPK manufacturing plant is a complete production line used to combine nitrogen, phosphorus, and potassium into compound fertilizer granules. These nutrients are blended according to specific formulas and processed into products that are easy to store, transport, and apply in the field.

Most NPK fertilizer plants work with raw materials such as urea, ammonium sulfate, ammonium phosphate, SSP, TSP, MOP, SOP, and selected additives. The exact combination depends on local soil needs, crop types, and market demand.

Applications of NPK Manufacturing Plants

NPK manufacturing plants are commonly used in large-scale fertilizer factories where consistent output and stable quality are required. They are also widely adopted by regional fertilizer suppliers and export-oriented producers.

Typical application scenarios include:

Production of balanced NPK fertilizers such as 15-15-15

High-nitrogen or high-potassium formulations

Crop-specific compound fertilizers

Customized products for different soil conditions

For many producers, flexibility is just as important as capacity. An adaptable NPK manufacturing plant makes this possible.

NPK Manufacturing Process Explained

- Raw Material Preparation

In most NPK manufacturing plants, raw materials are stored separately and weighed according to the selected formulation. Accurate batching is essential. Small deviations at this stage can lead to nutrient imbalance in the final product.

- Mixing and Granulation

After batching, materials are mixed and sent to the granulation system. Depending on plant design, granulation may be carried out using drum granulators, disc granulators, or extrusion systems.

Granulation improves fertilizer uniformity and reduces dust. It also makes the product easier to apply in the field.

- Drying and Cooling

Fresh granules usually contain excess moisture. A rotary dryer reduces moisture content to a stable level. The product then passes through a cooling system to improve mechanical strength and storage performance.

- Screening and Recycling

After cooling, granules are screened. Oversized and undersized particles are separated and returned to the granulation process. This step improves material utilization and helps maintain consistent granule size.

- Coating and Packaging

In some NPK manufacturing plants, a coating system is added to reduce dust and prevent caking. Finished products are then packaged for storage, distribution, or export.

Main Equipment in an NPK Manufacturing Plant

A standard NPK manufacturing plant typically includes:

Raw material batching system

Fertilizer mixer

Granulator

Rotary dryer and cooler

Screening equipment

Coating system (optional)

Dust collection system

The exact configuration may vary depending on raw materials, plant capacity, and local operating conditions.

Technical Advantages of Modern NPK Manufacturing Plants

Modern NPK manufacturing plants are designed for continuous and stable operation. Compared with simple blending systems, granulation-based plants offer better product quality and handling performance.

Key advantages include:

Uniform granule size

Flexible formulation adjustment

Lower dust levels

Improved storage stability

Reduced labor intensity

For manufacturers focused on long-term operation, these advantages often outweigh the initial investment.

Customization Options for NPK Fertilizer Plants

No two fertilizer projects are exactly the same. An NPK manufacturing plant can be customized based on:

Target production capacity

Available raw materials

Desired granule size

Automation level

Environmental and safety requirements

Many producers choose modular designs. This allows future expansion without major reconstruction.

Choosing the Right NPK Manufacturing Plant Supplier

From a project perspective, equipment selection is only one part of the process. A reliable NPK manufacturing plant supplier also provides process design support, installation guidance, and operator training.

Suppliers with real project experience are better prepared to address issues related to raw material variation, equipment wear, and long-term maintenance. This practical support often determines whether a plant performs as expected after commissioning.

Practical Project Experience and Global Use

NPK manufacturing plants are operating successfully in many regions, including Asia, Africa, South America, and the Middle East. Production capacities and configurations vary, but the basic process remains consistent.

In many cases, plants are designed with future upgrades in mind. This approach reduces risk and allows manufacturers to respond to market growth.

Industry Reference on Fertilizer Production

For general fertilizer production principles and nutrient management practices, industry guidance from the Food and Agriculture Organization (FAO) provides useful background information on fertilizer use and agricultural sustainability.

Conclusion

An NPK manufacturing plant is a long-term industrial investment rather than a short-term purchase. Stable production, formulation flexibility, and technical support all play an important role in overall performance. For fertilizer manufacturers, choosing the right process design and equipment configuration is often more important than simply maximizing output capacity.

Finished NPK fertilizer packaging system from LANE manufacturing plant

Discuss Your NPK Manufacturing Plant Project

If you are planning a new NPK manufacturing plant or evaluating an upgrade, early technical discussion can help avoid unnecessary cost and design limitations. A professional fertilizer plant supplier can provide practical suggestions based on raw materials, target capacity, and local production conditions.

Ready to choose the right NPK fertilizer solution? Contact LANE today to learn more about .

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Send a message to us