New Intelligent Drum Dryer Reduces Drying Energy by 25%

Article Overview – A Leap Forward in Fertilizer Drying Technology

The Drum Dryer has long been a critical component in organic fertilizer production, responsible for reducing moisture content to ensure product stability and quality. However, traditional dryers often struggle with high-energy consumption, uneven drying, and difficulty handling high-moisture materials. Today, a breakthrough is here. The next-generation drum dryer is engineered to tackle these exact challenges, integrating advanced thermal efficiency systems, intelligent moisture control, and robust design tailored for organic fertilizer lines. This innovation not only boosts throughput but also aligns with sustainable production goals—making it a game-changer for fertilizer manufacturers worldwide.

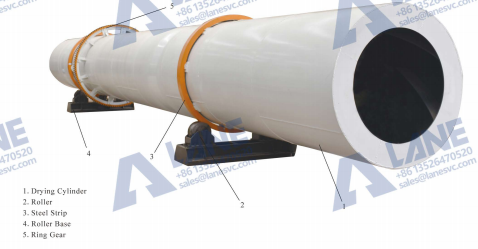

Technological Innovation – How the New Drum Dryer Works

1)Enhanced Thermal Efficiency & Heat Distribution

The core of the new drum dryer lies in its redesigned heat exchange mechanism. Unlike conventional models, it utilizes a multi-zone heating system that ensures uniform temperature distribution across the drum. This eliminates “hot spots” and “cold spots,” resulting in consistent moisture removal even for viscous or lumpy organic fertilizer mixes.

2)Intelligent Moisture & Temperature Control

Equipped with real-time sensors and an automated control panel, this organic fertilizer drum dryer continuously monitors product moisture and drum temperature. The system auto-adjusts heating parameters and rotation speed, ensuring optimal drying without over-energy use. This “smart drying” capability is key to handling high-moisture materials like fish waste or compost sludge efficiently.

3)Robust & Adaptable Design

Built with reinforced stainless steel and modular components, the dryer supports customization in drum diameter, length, and heating source (gas, steam, or electric). This flexibility allows integration into both new and existing fertilizer production lines, meeting outputs from 1 to 30 tons per hour.

Application & Advantages – Why Upgrade to the Next-Gen Drum Dryer?

Key Benefits for Organic Fertilizer Producers

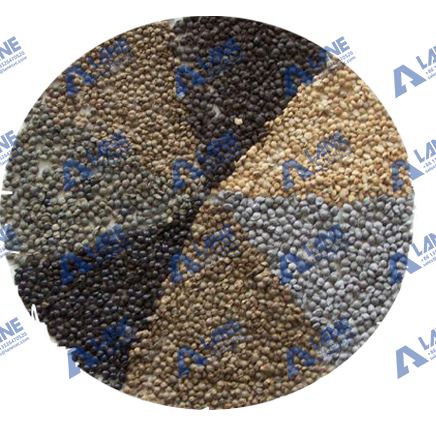

Higher Drying Efficiency: Reduces moisture from 30-40% to below 15% in a single pass, accelerating production cycles.

Energy Savings: Advanced insulation and heat recovery systems cut energy use by up to 25% compared to traditional dryers.

Improved Product Quality: Gentle yet consistent drying preserves nutrient content and granule integrity.

Low Maintenance: Easy-access design and wear-resistant materials minimize downtime.

Real-World Performance – A Case Snapshot

A fertilizer cooperative in Thailand recently integrated this next-gen drum dryer into their existing line. Results showed a 20% increase in daily output and a 15% reduction in fuel costs, while maintaining amino acid levels above 18% in their fish-based organic fertilizer.

Why Choose Our Drum Dryer Solution?

We combine decades of industrial drying expertise with continuous R&D, offering not just equipment but full technical support—from design to installation and maintenance. Our dryers are CE-certified and backed by a 24-month warranty.

Comparison: Traditional vs. Next-Gen Drum Dryer

| Feature | Traditional Dryer | Next-Gen Drum Dryer |

|---|---|---|

| Energy Consumption | High | Up to 25% lower |

| Drying Uniformity | Variable | Consistent, intelligent control |

| Maintenance Frequency | High | Low, modular design |

| Adaptability to Moisture | Limited | High, smart sensor adjustment |

How to Choose the Optimal Drying Solution for Your Production Line?

Key Selection Criteria: Looking Beyond Capacity

Whenrotary drum dryer, consider these factors alongside daily output:

- Material Characteristics: Initial moisture content, viscosity, particle size, and heat sensitivity determine the internal flight design and hot air strategy

- Heat Source Compatibility: Whether the system supports coal, gas, steam, biomass, or waste heat utilization to adapt

- System Integration: Ensuring the feed inlet height and discharge method seamlessly connect with upstream (e.g., crusher) and downstream (e.g., cooler) equipment to prevent bottlenecks.

- Process Scalability: Checking if the drum is pre-configured for adding future functions like spray nozzles for coating (e.g., microbial agents,functional organic fertilizers.

ROI Analysis: Calculating Long-Term Value

Although the initial investment for a new-generation intintelligent rotary drum dryer may be 15-25% higher, the comprehensive savings from energy efficiency, low maintenance, and high product yieldenergy efficiency, low maintenance, and high product yield typically recover the cost difference within 12-20 months. We provide an ROI calculation model based on real-time energy prices for accurate

Why Choose Our Drum Dryer Solution?

We combine decades of industrial drying expertise with continuous R&D, offering not just equipment but full technical support—from design to installation and maintenance. Our dryers are CE-certified and backed by a 24-month warranty, with remote monitoring options available for proactive maintenance.

Authoritative certification: why our drying technology meets international energy efficiency standards.

The intelligent control system of the new generation of dryers can adjust the temperature and speed in real time, which is highly with the core principle of precision agriculture – optimizing resource allocation through data. The Food and Agriculture Organization of the United Nations (FAO) clearly pointed out in its flagship report “The State of Food and Agriculture 2024” that empowering the transformation of the agricultural and food system through technological innovation is the key driving force to improve resource efficiency and sustainable production. This macro trend completely echoes with the intelligent sensing and automated control technology on which our equipment is based, and also verifies its advanced nature and industrial necessity from a strategic.

Ready to overcome your drying challenges?

[Schedule a Free Drum Dryer Consultation] Contact our engineers today for a free layout design and get a customized quote for a drum dryer that fits your production goals.

Send a message to us