Muriate of Potassium Production Line

Muriate of Potassium (MOP), also known as potassium chloride (KCl), is one of the most widely used fertilizers globally. It provides plants with essential potassium, which is crucial for water retention, photosynthesis, enzyme activation, and overall plant health.

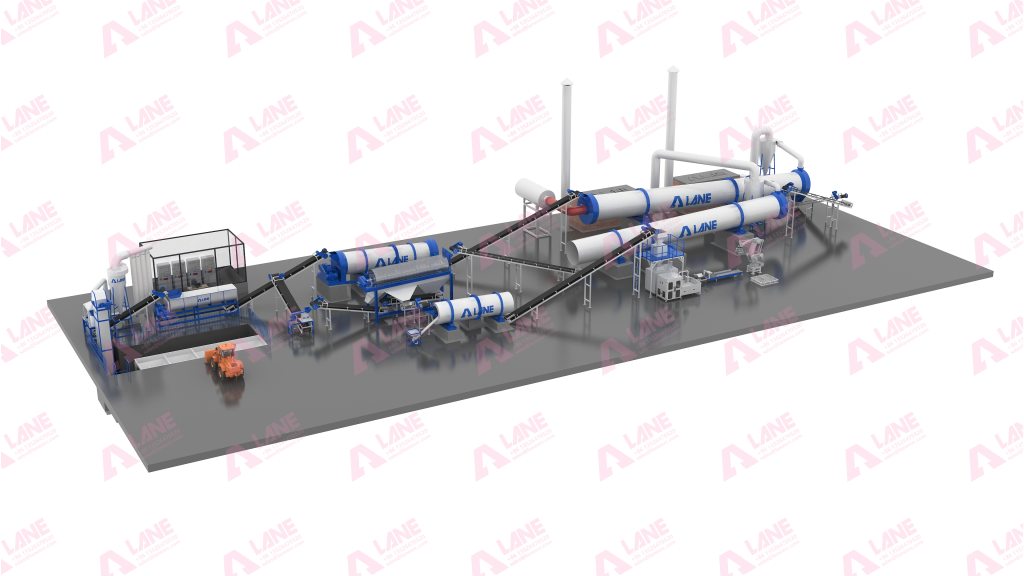

The Muriate of Potassium Production Line by LANE Group is designed to efficiently produce high-quality potassium fertilizer, offering consistent nutrient supply and enhanced agricultural productivity.

What We Offer:

- Production process design

- Professional technical guidance

- Equipment Customization & Manufacturing

- Overseas engineers on-site installation

- 5 Years Warranty

Main components

Raw Material Crushing→Mixing and Blending→Granulation→Drying and Cooling→Screening and Polishing→Automatic Packaging

Advantages

LANE Group’s Muriate of Potassium Production Line offers numerous advantages for fertilizer producers, helping them improve production efficiency, product quality, and cost-effectiveness.

High Efficiency and Output

The advanced machinery used in LANE’s MOP production line ensures high production efficiency, allowing manufacturers to produce large quantities of high-quality fertilizer in a short amount of time. The automation of critical processes, such as granulation, drying, and packaging, reduces manual labor and increases production speed, making it a cost-effective solution for large-scale operations.

Consistent Product Quality

One of the key benefits of LANE’s MOP production line is its ability to produce uniform, high-quality granules. The advanced granulation and screening systems ensure that the final product has a consistent particle size, improving its handling properties and ensuring even distribution when applied to crops. This consistency in product quality is essential for maximizing the fertilizer’s effectiveness in the field.

Energy Efficiency

LANE Group places a strong emphasis on energy efficiency throughout its production lines. The rotary dryer and cooler are designed to use minimal energy while maintaining optimal drying and cooling conditions for the granules. By reducing energy consumption, LANE’s MOP production line helps fertilizer manufacturers lower their operating costs and minimize their environmental impact.

Customizable Fertilizer Formulations

The flexibility of LANE’s production line allows for the blending of potassium chloride with other nutrients or additives, enabling the production of customized fertilizer formulations. This versatility is particularly beneficial for producers who want to create compound fertilizers that address specific soil or crop needs.

About LANE

Real-Life Shipping Cases of Our Products

Our Service

Do you want to get more informations?

Latest Articles & Tips

More-

09/27

read moreFertilizer Production Machinery: The Key to Addressing the Global Food Crisis

-

09/14

read moreMaximizing Efficiency: 58% MAP Mono Ammonium Phosphate Production Line Innovations

-

09/10

read moreLANE Group Completes Shipment of State-of-the-Art Di-Ammonium Phosphate Production Lines

-

09/23

read moreTop 4 Innovations in Superphosphate SSP Compound Production for LANE