Mono-ammonium Phosphate Production Line

The Mono-ammonium Phosphate (MAP) Production Line is a sophisticated facility dedicated to producing MAP fertilizer, a highly efficient source of phosphorus and nitrogen for plants. MAP is widely used in agriculture due to its high nutrient content and versatility, making it suitable for a variety of crops and soil types.

What We Offer:

- Production process design

- Professional technical guidance

- Equipment Customization & Manufacturing

- Overseas engineers on-site installation

- 5 Years Warranty

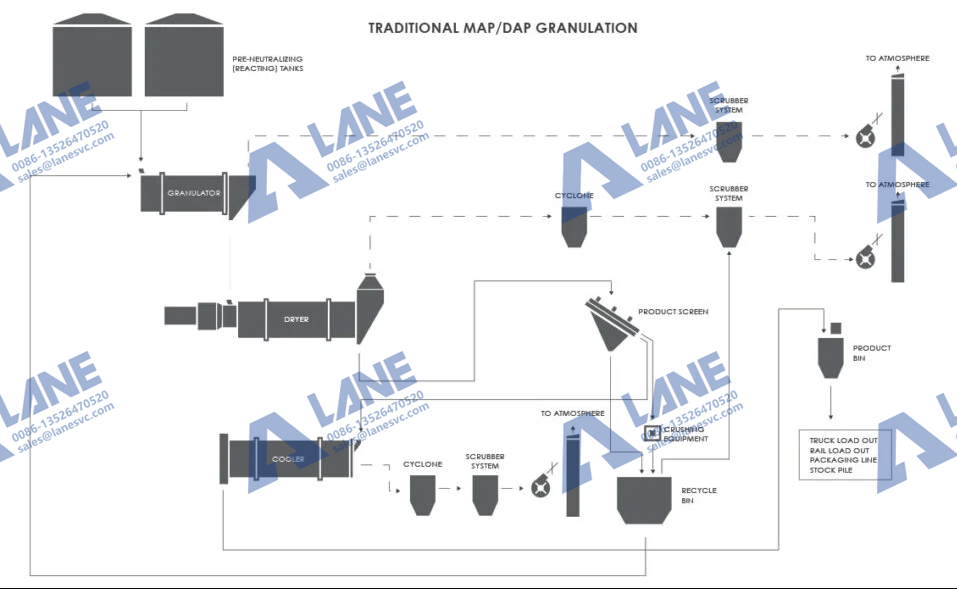

Lane Group’s Mono-ammonium Phosphate production line is an energy-saving, economical and efficient fertilizer production line that uses traditional methods to produce Mono-ammonium Phosphate fertilizer, which includes the following processes:

Raw Material Preparation – Neutralization – Drying and Cooling – Screening and Crushing – Storage and Packaging

LANE Group, as an environmental protection science and technology enterprise, the concept of environmental protection runs through all the time. The monoammonium phosphate production line developed by our company has the following environmental benefits:

- Waste Management

The production of MAP involves the generation of waste by-products, which must be carefully managed to minimize environmental impact. Recycling and reusing waste materials are common practices in modern production lines. - Energy Efficiency

The production process is energy-intensive, particularly during the drying and cooling stages. Advanced technologies and optimized processes are used to reduce energy consumption and lower the carbon footprint. - Sustainability

As part of the push towards sustainable agriculture, MAP production lines are increasingly adopting green practices, such as using renewable energy sources and reducing emissions.

Advantage

In addition to environmental benefits, our company adheres to the “customer’s success is our success” concept, the production of high-quality equipment, our products have been certified, the Mono-ammonium Phosphate production line has been tested and can meet the production requirements.

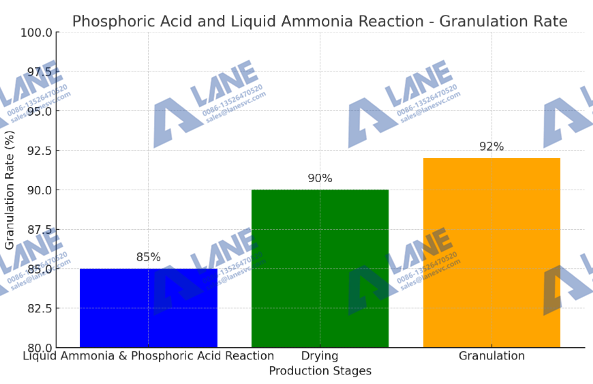

- High granulation rate: experiments have proved that liquid ammonia and phosphoric acid are mixed and reacted in a certain proportion, and the slurry generated by the reaction is dried to get Mono-ammonium Phosphate particles, and the granulation rate reaches more than 90%.

- Low pollution: adopting advanced exhaust gas recovery device to reduce the impact on the environment.

- High efficiency: high-quality equipment and customized design can meet different requirements in different situations.

- Technical certifications: Our equipment is certified and accredited.

Real-Life Shipping Cases of Our Products

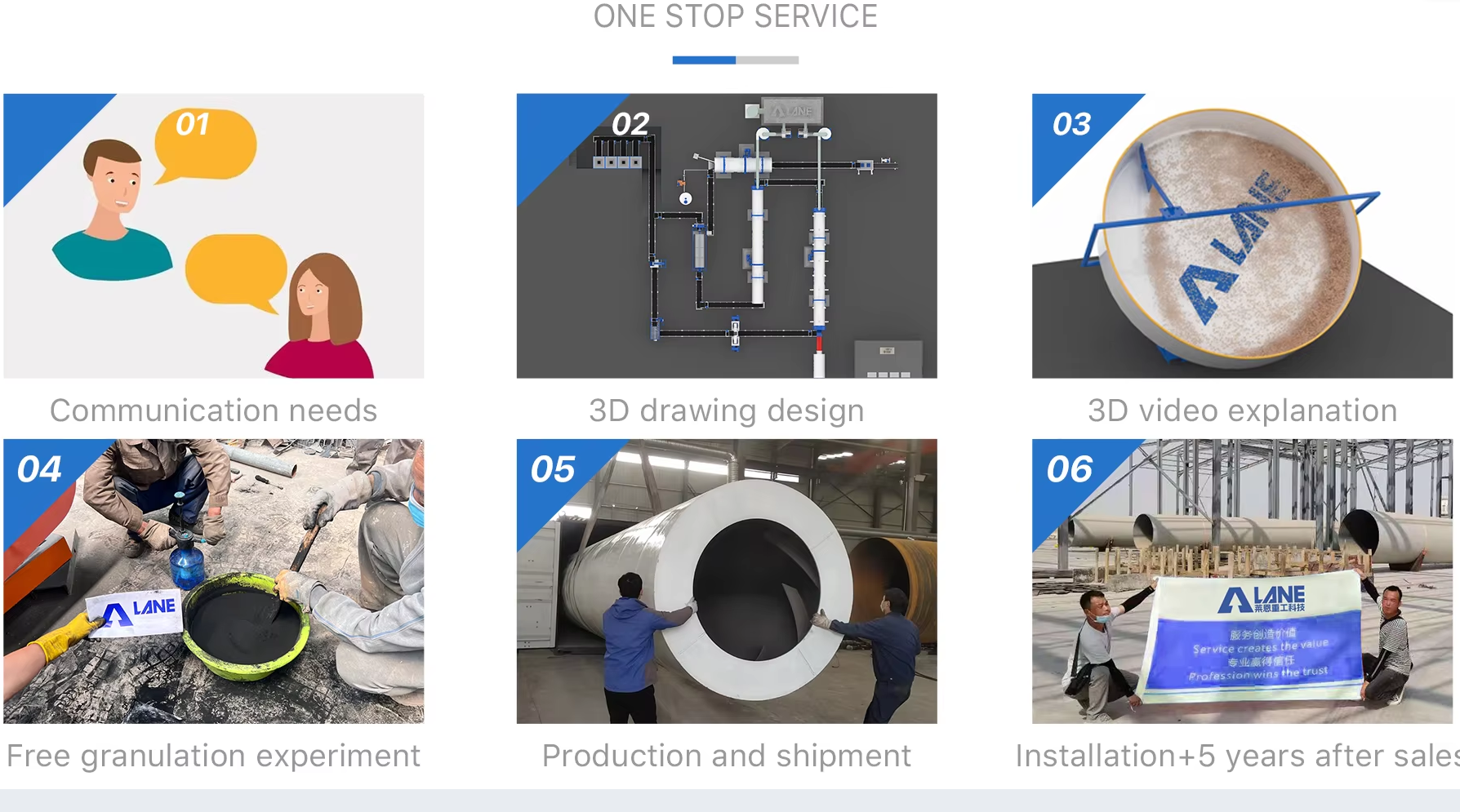

Our Service

- Free Granulation Experiment

- 3D Drawing Design

- 5 Years Warranty

Want to know more? Contact Us!

![]()