Best Mono-ammonium Phosphate (MAP) Production Line: Workflow & Key Equipment

What Is a Mono-ammonium Phosphate (MAP) Production Line?

A Mono-ammonium Phosphate (MAP) production line refers to a well-engineered system designed to convert phosphoric acid and ammonia into high-quality MAP fertilizer with minimal waste and maximum operational efficiency. MAP fertilizer is a widely used phosphorus and nitrogen fertilizer, valued for its water solubility and effectiveness across a range of crops and soil types.

The goal of a MAP production line is not simply to produce MAP, but to do so consistently and sustainably, meeting strict quality standards while controlling energy use and environmental impact.

Raw Material Preparation and Chemical Reaction

The first step in a Mono-ammonium Phosphate (MAP) production line begins with careful raw material handling.

High-purity phosphoric acid and ammonia serve as the foundational inputs. The phosphoric acid quality affects nutrient content and impurity levels in the final product. Ammonia provides the nitrogen component needed for MAP.

In the reactor stage, phosphoric acid and ammonia are mixed under controlled temperature and pH to produce MAP through neutralization. Precise dosing, mixing speed, and temperature regulation are critical to achieving a complete reaction and avoiding unreacted residues.

Slurry Concentration and Cooling Crystallization

After the neutralization reaction, the resulting liquid MAP slurry must be cooled to initiate crystallization. In a high-efficiency MAP production line, controlled cooling crystallizers are used to ensure uniform nucleation and crystal growth.

The cooled crystals are then separated from the mother liquor and dehydrated. Efficient filtration and dewatering systems reduce moisture content before drying, improving energy use and preparing the material for subsequent processing steps.

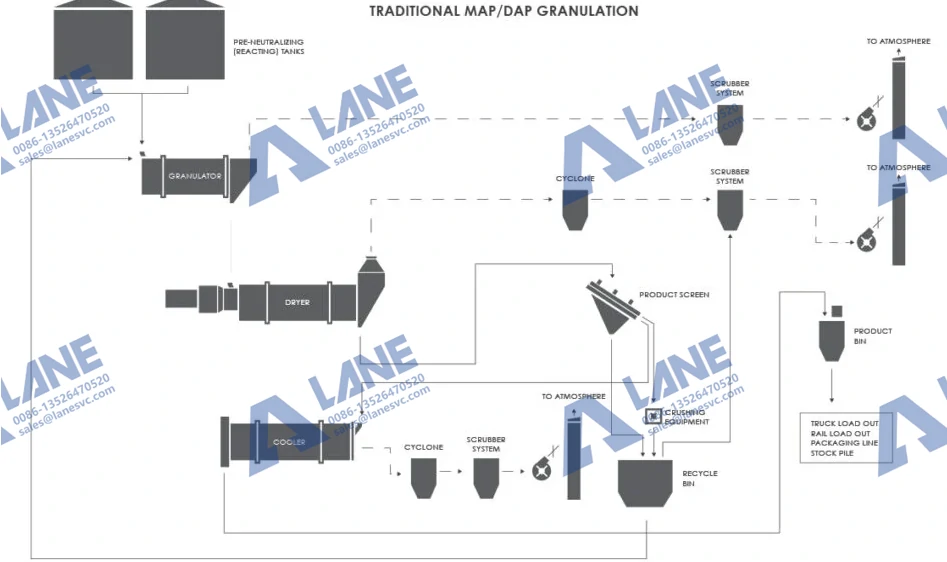

Granulation and Particle Formation

Granulation is a defining stage in the Mono-ammonium Phosphate (MAP) production line because it impacts particle size, hardness, and application performance.

Common granulation equipment includes disc granulators or specialized MAP granulators. Disc granulators offer precise control over granule size (typically 2–4 mm) and uniform density, which supports even nutrient distribution in the field.

In high-efficiency lines, granulators may be equipped with automatic water spraying systems and variable speed drives to maintain consistent particle formation with minimal waste.

Drying and Cooling Systems

Once granulated, the MAP material contains excess moisture, which must be removed before packaging.

Rotary dryers are typically used to reduce moisture content to below 2 %, ensuring stability in storage and transport. These dryers use hot air in a controlled airflow pattern to avoid overheating or degrading the fertilizer.

Following drying, MAP granules pass through coolers to lower their temperature before screening. Effective cooling improves granule strength and reduces clumping.

Screening and Recycling

The next step in the Mono-ammonium Phosphate (MAP) production line for best involves screening the dried and cooled granules.

Vibrating screens separate qualified particles from oversized or undersized material. Screening systems with anti-blocking meshes improve throughput and reduce downtime. Oversize and undersize particles are typically recycled back into the granulation section for reprocessing, improving raw material utilization.

Coating, Packaging, and Storage

High-quality MAP fertilizer often undergoes a coating step to improve storage stability and reduce caking. A light layer of anti-caking agent or polishing oil helps maintain product integrity during long-term storage.

Automated weighing and packaging systems ensure efficient and accurate bagging of finished granules. PLC-controlled packaging lines reduce labor dependence and improve throughput, ensuring MAP fertilizer is ready for distribution with minimal handling error.

Environmental and Efficiency Considerations

Modern MAP production lines emphasize sustainability and energy efficiency. Advanced exhaust gas recovery and dust collection systems reduce emissions and improve workplace safety. Waste by-products are managed or reused where possible to minimize environmental impact.

Energy usage is particularly critical during drying and cooling, and optimized airflow designs or heat recovery systems significantly reduce fuel consumption.

Quality Control and Process Optimization

A Mono-ammonium Phosphate (MAP) production line integrates quality checks at every stage of production. From raw material inspection to final packaging, parameters such as nutrient content, moisture level, and particle size distribution must be monitored.

Automated sensors and real-time data logging help operators adjust key settings, such as feed rates and drying temperatures, to maintain product consistency and minimize downtime.

Conclusion

To better understand the broader role of phosphate fertilizers in global agriculture, it is helpful to reference independent industry and institutional sources. These materials provide a neutral overview of phosphate fertilizer types, production principles, and application characteristics, offering useful context beyond individual equipment or production line configurations.

A well-engineered Mono-ammonium Phosphate (MAP) production line delivers stable, high-quality fertilizer with efficient resource use and reduced environmental impact. By controlling each step — from raw material preparation to granulation, drying, and packaging — manufacturers can achieve consistent performance and long-term production reliability.

Whether serving large agricultural markets or regional fertilizer distributors, a best-designed MAP production line supports both operational efficiency and sustainable fertilizer production.

Send a message to us