Large Inclination Belt Conveyor

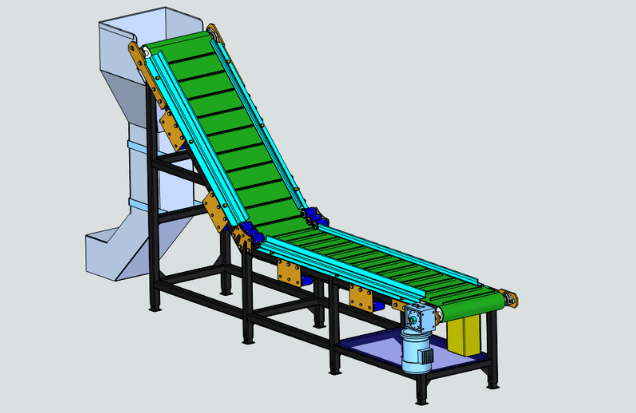

A Large Inclination Belt Conveyor is a specialized type of conveyor system designed to transport bulk materials over steep inclines, typically up to 90 degrees. Unlike traditional belt conveyors, which are limited to shallow inclines, the large inclination model features a belt with a corrugated sidewall and cross cleats, ensuring that materials remain securely on the belt as they are moved upwards.

This conveyor is widely used in fertilizer production for transporting raw materials, semi-finished products, and final products across different levels of the production facility. Its ability to handle steep inclines makes it ideal for optimizing plant layouts and reducing the need for long, horizontal conveyors.

Device Details

Key Feature

High Transport Capacity: Designed to handle large volumes of materials, the conveyor can transport significant quantities of fertilizer products over steep inclines without sacrificing speed or efficiency.

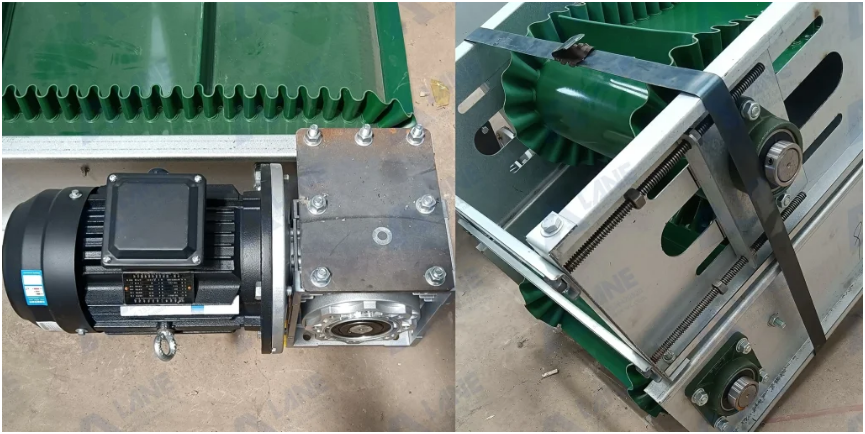

Corrugated Sidewall and Cleat Design: The belt is fitted with corrugated sidewalls and cross cleats, ensuring that materials are securely contained on the belt even when being transported at steep angles. This design prevents material spillage and ensures smooth, continuous transport.

Steep Incline Capability: The conveyor is capable of handling inclines of up to 90 degrees, making it ideal for transporting materials vertically or at sharp angles. This feature is particularly useful in space-constrained production facilities where maximizing vertical space is essential.

Durable Construction: Built with high-quality, wear-resistant materials, LANE Group’s Large Inclination Belt Conveyor is designed for long-term use in harsh industrial environments. It can handle abrasive materials, such as fertilizer granules and powders, without experiencing significant wear and tear.

Energy Efficiency: The conveyor is engineered to operate with minimal energy consumption, contributing to lower operational costs while maintaining high performance.

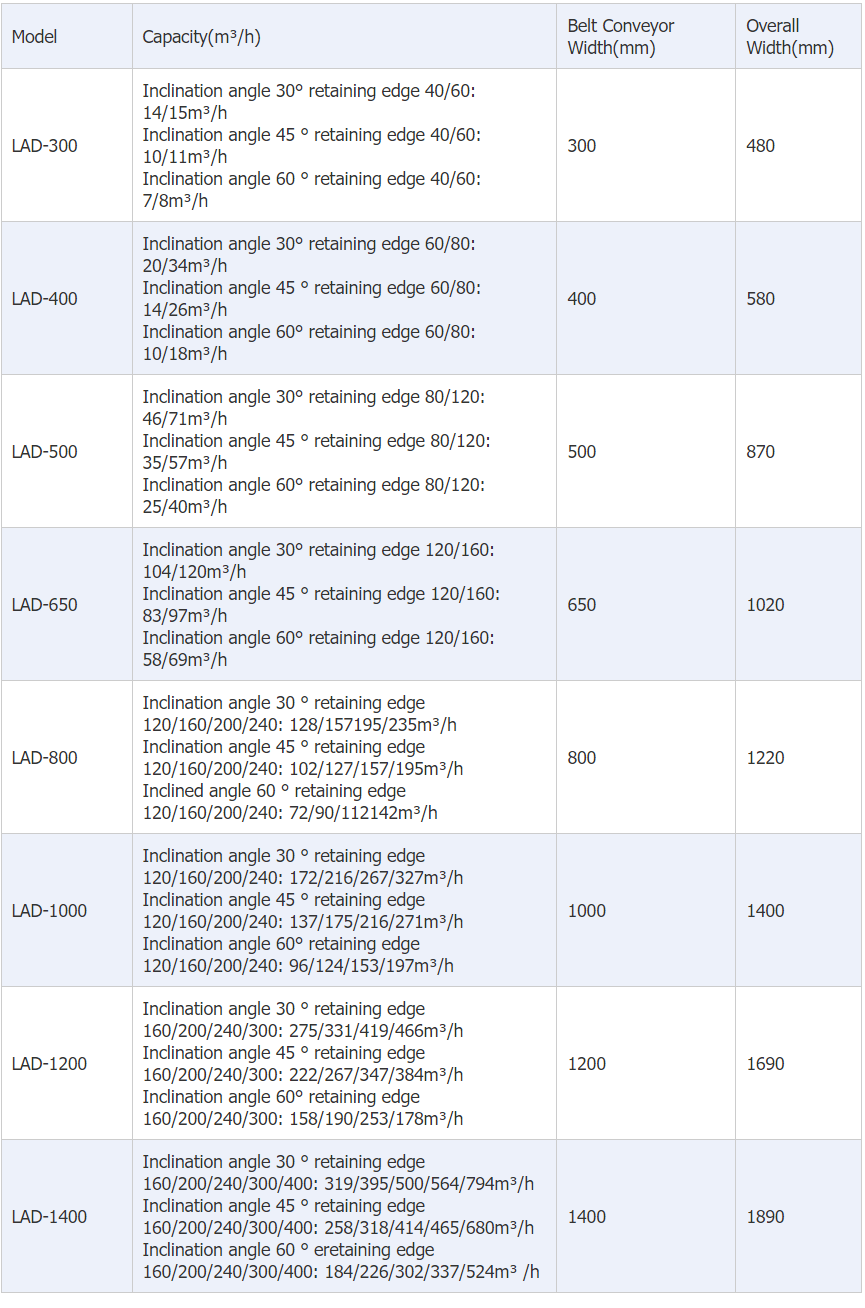

Customizable Design: LANE Group offers various belt widths, sidewall heights, and cleat designs to tailor the conveyor to specific material handling requirements. This customization ensures optimal performance regardless of the type of material being transported.

Low Maintenance Requirements: The conveyor is designed for easy access, making maintenance and cleaning quick and simple. This reduces downtime and keeps production running smoothly.

Application

Raw Material Transport: The conveyor is commonly used to move raw materials, such as phosphate, nitrogen, or potash, from storage areas to processing equipment. Its ability to handle steep inclines allows for efficient use of vertical space in production plants.

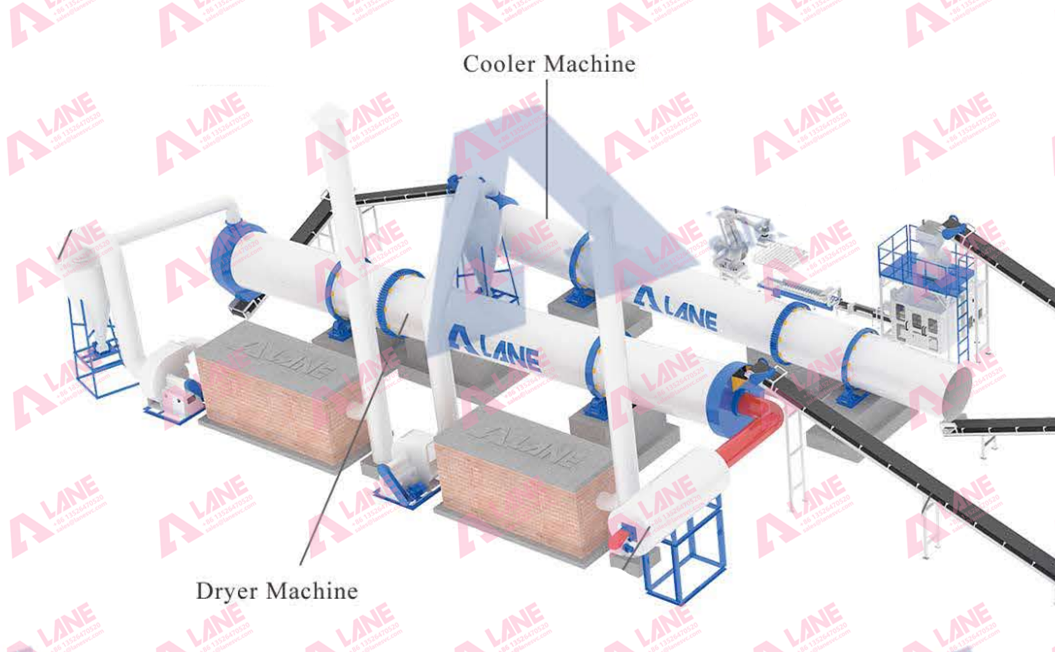

Intermediate Processing: During the production process, the conveyor efficiently moves materials from one stage to another, such as from mixers to granulators or from granulators to dryers. This helps streamline the entire production process and reduces the need for complex material handling systems.

Product Transfer Between Floors: The large inclination design makes the conveyor ideal for transporting materials between different floors or levels of the production facility, reducing the need for long, horizontal conveyor systems and optimizing plant layout.

Waste Material Handling: In addition to transporting raw materials and finished products, the conveyor can also be used to remove waste and byproducts from the production line. Its steep incline capability allows waste to be efficiently transported to disposal areas.

Advantage

Maximized Use of Vertical Space: The conveyor’s ability to handle steep inclines allows production facilities to utilize vertical space more effectively. This helps reduce the footprint of conveyor systems and frees up valuable floor space for other equipment.

Improved Production Efficiency: By transporting materials across steep inclines, the conveyor helps streamline material handling, reducing the need for complex multi-stage handling systems and increasing overall production efficiency.

Reduced Material Spillage: The corrugated sidewall and cleat design ensure that materials remain securely on the belt, minimizing spillage and material loss during transport. This contributes to higher yields and reduces waste.

Cost Savings: With its energy-efficient design and low maintenance requirements, the Large Inclination Belt Conveyor helps reduce operational costs over time. Its durable construction also minimizes the need for frequent repairs or replacements, further reducing expenses.

Versatility in Material Handling: The conveyor can handle a wide variety of materials, including powders, granules, and even sticky substances. This versatility makes it suitable for a range of fertilizer products, from organic to chemical fertilizers.

Improved Plant Layout Flexibility: The conveyor’s steep incline capability allows for greater flexibility in designing production plants, enabling more compact and efficient layouts. This is especially valuable in facilities where space is limited.

About LANE

Our Service

Latest Articles & Tips

More-

12/20

DAP Pellet Machine: A Key Component in Efficient Fertilizer Production

read more -

09/29

read moreUnlocking Nutrient Potential: The Single Calcium Phosphate Fertilizer Production Explained

-

01/19

Maintenance Cost of SSP Granulation Equipment: How to Minimize Expenses and Maximize Uptime

read more -

12/02

Triple Superphosphate and DAP: Which Fertilizer is Best for Your Crops?

read more