Fertilizer Pellet Production Line: Streamlining Fertilizer Manufacturing for High-Quality Granules

The demand for high-quality fertilizers is increasing, driven by the need to boost agricultural productivity. Fertilizer pellet production lines are essential to meet this demand by converting raw materials into uniform, high-quality fertilizer pellets. These machines not only ensure the proper blending of ingredients but also optimize the production process to improve both the efficiency and quality of the final product. In this article, we will discuss the components, advantages, and processes of a fertilizer pellet production line.

What is a Fertilizer Pellet Production Line?

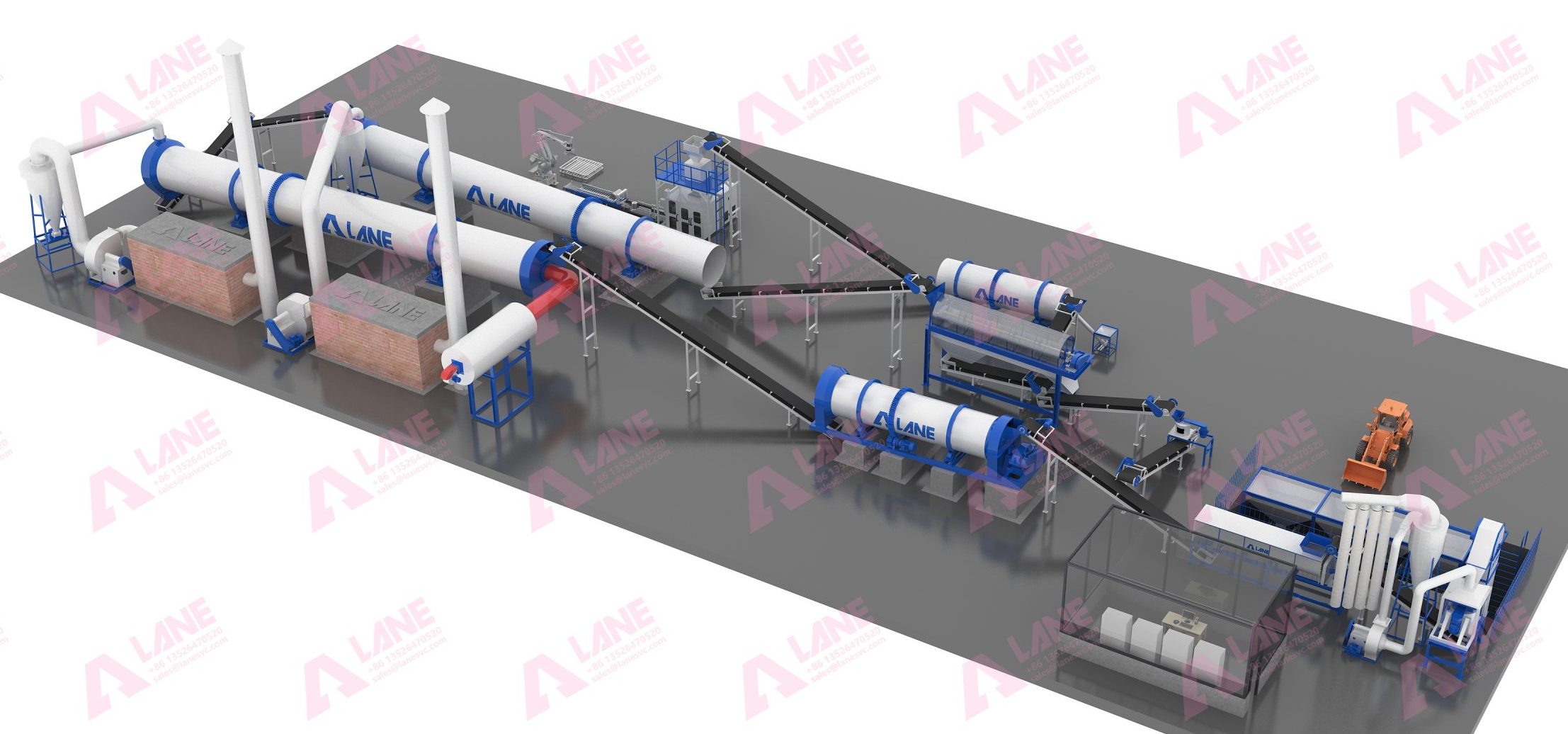

A fertilizer pellet production line is a complete system designed to convert raw materials into uniform, granulated fertilizers. The process involves several stages, including material preparation, granulation, drying, cooling, and packaging. By ensuring a consistent size and shape, this equipment improves the application of fertilizers, leading to better nutrient delivery to plants and more efficient use of resources.

Key Components of a Fertilizer Pellet Production Line

A typical fertilizer pellet production line consists of the following key components:

Crushing and Grinding Equipment

The raw materials, such as ammonium nitrate, phosphate, or organic matter, are first ground into a fine powder. This is done using crushers and grinders to ensure the materials are of the right size for the granulation process.Mixing Equipment

In this step, the powdered raw materials are thoroughly mixed with water and/or other additives to form a homogenous mixture. Horizontal mixers or double-shaft mixers are typically used for efficient blending.Granulation Equipment

The heart of the pellet production line is the granulator. The rotary drum granulator or flat-die granulator forms the raw mixture into small, uniform pellets. This process plays a critical role in determining the size and quality of the pellets.Drying Equipment

After the pellets are formed, they need to be dried to reduce moisture content. Rotary dryers or fluidized bed dryers are used in this stage to ensure that the pellets are dry, preventing clumping and ensuring their durability during storage and transportation.Cooling Equipment

Once the pellets are dried, they are cooled to prevent them from becoming too soft. Cooling machines such as rotary coolers or counter-flow coolers are used to bring down the temperature and solidify the pellets.Screening and Sorting

After cooling, the pellets are screened to remove any undersized or oversized particles. This ensures that only uniformly sized pellets are packaged for sale.Packaging Equipment

The final step in the fertilizer pellet production line is packaging. Automatic packing machines are used to efficiently package the finished fertilizer pellets into bags or other containers for distribution.

Advantages of a Fertilizer Pellet Production Line

High-Quality Granules

A well-designed fertilizer pellet production line ensures that the final product consists of uniform, high-quality pellets. This uniformity improves the fertilizer’s ability to deliver nutrients to plants more effectively, leading to better crop yields.Increased Efficiency

Modern fertilizer pellet production lines are highly automated, reducing the need for manual labor and increasing overall production efficiency. Automated control systems ensure that the production process runs smoothly and consistently.Cost-Effectiveness

By optimizing the production process, fertilizer pellet production lines help reduce waste and minimize energy consumption. This makes the production of fertilizers more cost-effective, allowing manufacturers to offer competitive pricing.- Environmental Sustainability

Fertilizer pellet production lines also contribute to environmental sustainability by reducing the loss of nutrients and minimizing the use of excess raw materials. Additionally, the production process is more efficient, reducing the carbon footprint of fertilizer manufacturing.

How a Fertilizer Pellet Production Line Works

The production process begins with the preparation of raw materials, which are crushed, ground, and mixed. The mixture is then fed into a granulator where it is formed into small pellets. These pellets are dried, cooled, and screened to ensure uniform size and quality. Finally, the finished product is packaged and ready for distribution.

The key to the success of a fertilizer pellet production line lies in the precision of each stage. From mixing to granulation to drying, each step must be carefully controlled to ensure that the fertilizer is of the highest quality.

Choosing the Right Fertilizer Pellet Production Line

TSP production line

When selecting a fertilizer pellet production line, it is important to consider the following factors:

- Production Capacity: Choose a production line that matches your output requirements. High-capacity lines are suited for large-scale operations, while smaller lines may be more suitable for niche markets.

- Material Compatibility: Ensure the equipment can handle the specific types of raw materials you intend to use, whether they are organic or synthetic fertilizers.

- Automation Level: Higher levels of automation can improve efficiency, reduce labor costs, and improve product consistency.

- Energy Efficiency: Look for production lines that are designed to minimize energy consumption, reducing operating costs over the long term.

- Maintenance and Service: Select equipment from a reputable supplier who offers comprehensive maintenance support and after-sales service.

Conclusion

A fertilizer pellet production line is an essential investment for any fertilizer manufacturer aiming to produce high-quality, uniform granules. By streamlining the production process, this equipment enhances efficiency, reduces costs, and ensures the production of fertilizers that meet the needs of modern agriculture. If you’re looking to improve your fertilizer manufacturing process, investing in a fertilizer pellet production line is a step towards greater productivity and sustainability.

Call to Action

If you’re interested in learning more about fertilizer pellet production lines and how they can enhance your fertilizer production, contact us today to discuss the best solution for your needs.

Send a message to us