Fertilizer Manufacturing Plant Cost: Practical Investment Guide for Fertilizer Producers

Fertilizer manufacturing plant cost is one of the first concerns for investors and producers planning a new fertilizer facility. Cost structure varies widely depending on fertilizer type, production capacity, raw materials, and local conditions.

In practice, there is no fixed price for a fertilizer plant. Instead, total investment is formed by a combination of equipment cost, civil construction, utilities, installation, and long-term operating expenses. Understanding these components helps avoid underestimating capital requirements.

What Determines Fertilizer Manufacturing Plant Cost?

The cost of a fertilizer manufacturing plant depends on multiple technical and commercial factors. Early-stage planning should focus on realistic assumptions rather than nominal equipment prices.

Key cost drivers include:

Fertilizer type (SSP, TSP, NPK, SOP, urea-based products)

Designed production capacity

Process complexity

Raw material availability

Local labor and energy costs

Plants producing specialty or controlled-release fertilizers usually require higher investment than basic fertilizer lines.

Capacity Scale and Its Impact on Plant Cost

Production capacity has a direct and often underestimated impact on fertilizer manufacturing plant cost. Small-scale plants usually require lower initial investment, but unit production cost tends to be higher due to limited automation and lower energy efficiency.

Medium-capacity plants often provide the best balance between capital investment and operating efficiency. Equipment utilization is higher, and auxiliary systems such as dust collection and material handling are better optimized.

Large-scale plants require significant upfront investment. However, they benefit from economies of scale. Energy consumption per ton is lower, and labor cost per unit decreases with higher automation. Choosing the right capacity depends on market demand, raw material availability, and long-term production strategy.

Equipment Cost Breakdown

Core Production Equipment

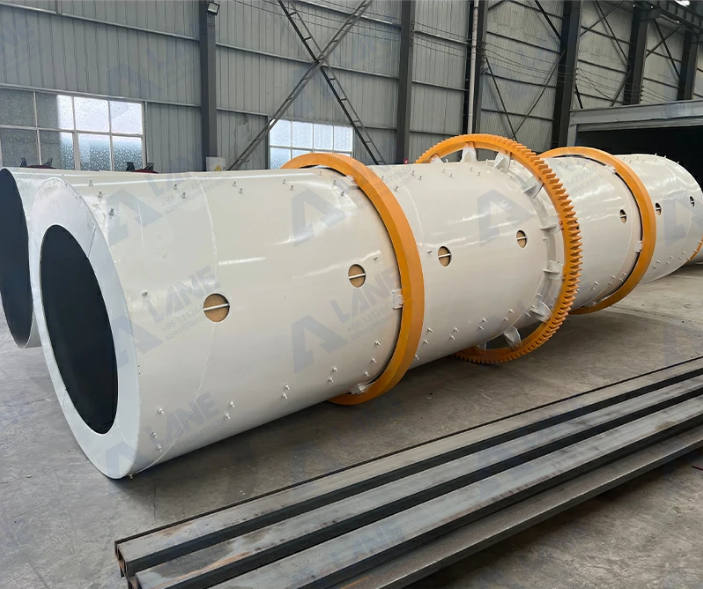

Core equipment accounts for a significant portion of fertilizer manufacturing plant cost. This includes crushers, mixers, reactors, granulators, dryers, coolers, and screening machines.

Equipment material selection also affects cost. Corrosion-resistant or high-temperature equipment increases initial investment but reduces maintenance expenses.

Auxiliary Systems

Auxiliary systems are often underestimated during budgeting. These include:

Dust collection systems

Gas treatment units

Electrical and automation systems

Although these systems do not directly produce fertilizer, they are essential for stable and compliant operation.

Civil Construction and Infrastructure Cost

Civil works form another major part of fertilizer manufacturing plant cost. Foundations, buildings, storage areas, and access roads must be designed according to equipment layout and local regulations.

Infrastructure cost varies significantly by region. Soil condition, climate, and construction standards all influence the final budget.

Utilities and Energy Consumption

Energy consumption directly affects both capital and operating cost. Fertilizer plants require electricity, water, and sometimes steam or fuel.

Plants with drying or high-temperature processes generally consume more energy. Proper process design and energy-efficient equipment help control long-term expenses.

Installation and Commissioning Expenses

Installation and commissioning costs include equipment erection, piping, electrical work, and trial operation. Skilled labor availability influences this cost component.

A realistic installation budget reduces the risk of delayed startup and unexpected expenses.

Operating Cost Considerations

- Raw Material Cost

Raw materials represent the largest ongoing expense for most fertilizer manufacturing plants. Price volatility of phosphate rock, potassium sources, sulfuric acid, or urea directly affects profitability.

Plants located close to raw material sources usually enjoy lower operating costs.

- Maintenance and Labor Cost

Maintenance cost depends on equipment quality and operating discipline. Preventive maintenance reduces downtime and extends service life.

Labor cost varies by region and automation level. Automated plants require fewer operators but higher upfront investment.

Cost Differences by Fertilizer Type

Fertilizer manufacturing plant cost differs significantly depending on product type:

SSP plants: Lower investment, simpler process

TSP plants: Higher cost due to phosphoric acid handling

NPK plants: Flexible but more complex equipment

SOP plants: Higher technical and material requirements

Controlled-release fertilizers: Premium investment level

Understanding these differences helps align investment with market demand.

Hidden Costs Investors Often Overlook

Some costs are not obvious during initial planning:

Environmental compliance upgrades

Spare parts inventory

Operator training

Process optimization after startup

Ignoring these factors often leads to budget overruns.

How to Optimize Fertilizer Manufacturing Plant Cost

Cost optimization does not mean reducing quality. Instead, it focuses on balanced design decisions.

Effective approaches include:

Selecting appropriate plant capacity

Matching equipment to raw materials

Avoiding over-automation

Planning phased expansion

Choosing experienced equipment suppliers

Early technical consultation helps prevent costly design changes later.

Choosing the Right Fertilizer Plant Supplier

An experienced supplier plays a key role in controlling fertilizer manufacturing plant cost. Beyond equipment pricing, suppliers should provide process design, layout optimization, and commissioning support.

A reliable supplier focuses on long-term plant performance rather than short-term savings.

Conclusion

For internationally recognized fertilizer classification and quality benchmarks, manufacturers can consult the FAO fertilizer specifications and quality standards, which provide standardized guidance on fertilizer definitions, nutrient contents, and product specifications used in global agricultural markets.

Fertilizer manufacturing plant cost is influenced by many technical and economic factors. A successful investment depends on realistic budgeting, proper process selection, and long-term operating considerations. By understanding cost structure in detail, investors can make informed decisions and reduce financial risk.

Ready to choose the right fertilizer production solution? Contact LANE today to learn more about .

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Send a message to us