Fertilizer Manufacturing Equipment Used in Modern Fertilizer Plants

Overview of Fertilizer Manufacturing Equipment

Fertilizer manufacturing equipment refers to the complete set of machines used to convert raw materials into finished fertilizer products. These systems are designed to handle crushing, mixing, granulation, drying, cooling, and screening in a continuous and controlled manner.

In modern fertilizer plants, equipment selection directly affects production efficiency, product quality, operating stability, and long-term maintenance cost. Whether producing SSP, TSP, SOP, NPK, or compound fertilizers, a well-matched equipment configuration is essential for stable plant operation.

Core Fertilizer Manufacturing Equipment

The core fertilizer manufacturing equipment forms the backbone of the entire production line. Each machine plays a specific role in ensuring consistent output and product uniformity.

Crushing Equipment

Crushing equipment is used to reduce the particle size of raw materials such as phosphate rock, potassium salts, or recycled fertilizer fines. Uniform particle size improves mixing efficiency and ensures smoother downstream processing.

Hammer crushers and chain crushers are commonly used due to their simple structure and stable operation.

Mixing Equipment

Mixers ensure even distribution of raw materials before granulation or chemical reaction. Uniform mixing is critical for nutrient consistency in the final fertilizer product.

Horizontal mixers and double-shaft mixers are widely applied in fertilizer manufacturing plants because they provide high mixing efficiency with minimal residue.

Granulation Systems in Fertilizer Plants

Granulation equipment is the core component of fertilizer manufacturing equipment and has the greatest impact on final product appearance and strength.

Rotary drum granulators are commonly used for large-capacity fertilizer plants. They offer stable operation and high granulation efficiency. Disc granulators are suitable for smaller plants or specialized fertilizer formulations.

Different fertilizer types require different granulation approaches. For example, SSP and TSP production lines often integrate reaction and granulation processes, while compound fertilizer plants emphasize flexibility and formulation adjustment.

Drying, Cooling, and Screening Equipment

After granulation, fertilizer granules must be processed through drying, cooling, and screening systems to achieve market-ready quality.

Drying Equipment

Dryers remove excess moisture from fertilizer granules, improving storage stability and reducing caking risks. Rotary dryers are widely used due to their high thermal efficiency and adaptability to various materials.

Cooling Equipment

Cooling equipment reduces granule temperature after drying. Proper cooling prevents granule deformation and improves mechanical strength during packaging and transportation.

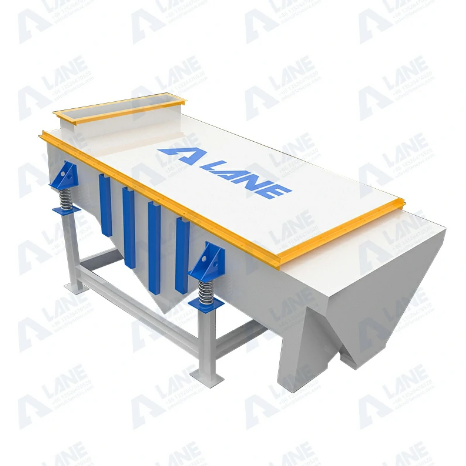

Screening Equipment

Screening machines separate qualified granules from oversized or undersized particles. Unqualified material is recycled back into the granulation system, improving raw material utilization.

Auxiliary Equipment and Environmental Systems

Auxiliary systems are often overlooked, but they play a critical role in plant stability and environmental compliance.

Dust collection systems reduce airborne particles and improve workplace safety. Conveying systems ensure smooth material transfer between equipment. Automated control systems improve operational accuracy and reduce labor dependency.

In regions with strict environmental regulations, gas treatment units and enclosed conveying systems are essential parts of fertilizer manufacturing equipment.

Maintenance Cost and Lifecycle Considerations of Fertilizer Manufacturing Equipment

Maintenance cost is a long-term factor that directly affects the overall performance of fertilizer manufacturing equipment. While initial equipment investment is important, many plants underestimate the impact of maintenance on total operating cost.

Wear parts such as crusher hammers, mixer liners, granulator lifters, and dryer flights require periodic replacement. The frequency of replacement depends on raw material hardness, moisture content, and operating conditions. Poor-quality materials or improper equipment selection often lead to higher downtime and unstable production.

Regular preventive maintenance helps extend equipment service life. Simple actions, such as lubrication management, alignment inspection, and cleaning of dust accumulation points, reduce unexpected shutdowns. Plants that follow structured maintenance schedules generally experience lower repair costs and more stable output over time.

When evaluating fertilizer manufacturing equipment, it is important to consider spare parts availability and technical support. Equipment designed with standardized components and easy-access maintenance points typically results in lower lifecycle cost and smoother plant operation.

Automation Trends in Modern Fertilizer Manufacturing Plants

Automation has become an increasingly important part of modern fertilizer manufacturing equipment. Automated systems improve process control, reduce labor dependency, and enhance product consistency.

Batching and weighing systems allow precise raw material dosing, which is especially critical for compound fertilizers. Centralized control systems monitor key parameters such as temperature, moisture, and granule size in real time, enabling operators to make quick adjustments.

Automation also improves safety and environmental performance. Remote monitoring reduces manual intervention in high-temperature or dusty areas. Integrated alarms and data logging help identify process deviations before they cause equipment damage or product quality issues.

As fertilizer plants move toward higher efficiency and sustainability, automation is no longer an optional feature. Well-designed automated systems support long-term production stability and lower overall operating cost.

Equipment Configuration for Different Fertilizer Types

Different fertilizer products require different equipment configurations.

SSP and TSP plants focus on reaction control, corrosion-resistant materials, and continuous granulation.

SOP production plants emphasize crystallization, drying precision, and anti-caking systems.

NPK and compound fertilizer plants require flexible batching and precise mixing equipment to support multiple formulations.

Selecting equipment based on fertilizer type ensures both product quality and operational efficiency.

How to Choose the Right Fertilizer Manufacturing Equipment

Choosing suitable fertilizer manufacturing equipment requires technical evaluation rather than simple price comparison. Key factors include plant capacity, fertilizer type, raw material characteristics, and local environmental requirements.

Reliable equipment suppliers provide customized solutions instead of standard layouts. Long-term factors such as maintenance cost, spare parts availability, and technical support should also be considered during decision-making.

Conclusion

For additional technical insights into fertilizer manufacturing systems and the latest production technology discussions, readers may refer to the FAO workshop on phosphate fertilizer production technology, which covers key approaches to fertilizer process optimization, equipment needs, and industry challenges faced by production engineers.

Fertilizer manufacturing equipment determines not only production capacity but also product quality and long-term operating cost. A well-designed equipment configuration supports stable operation, efficient energy use, and consistent fertilizer output.

For manufacturers planning new fertilizer plants or upgrading existing facilities, careful equipment selection is the foundation of sustainable and profitable fertilizer production.

Ready to choose the right fertilizer production solution? Contact LANE today to learn more about .

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Send a message to us