Disc Mixer

In the world of fertilizer production, achieving a uniform blend of raw materials is essential for producing consistent, high-quality products. The Disc Mixer, a vital component in fertilizer manufacturing, plays a crucial role in ensuring that different materials are thoroughly mixed, leading to a homogeneous final product. LANE Disc Mixer is engineered to deliver superior mixing performance, making it an indispensable tool for any fertilizer production line.

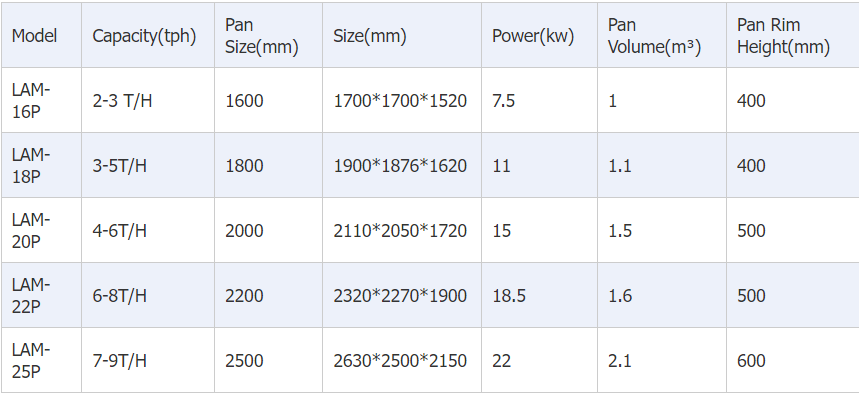

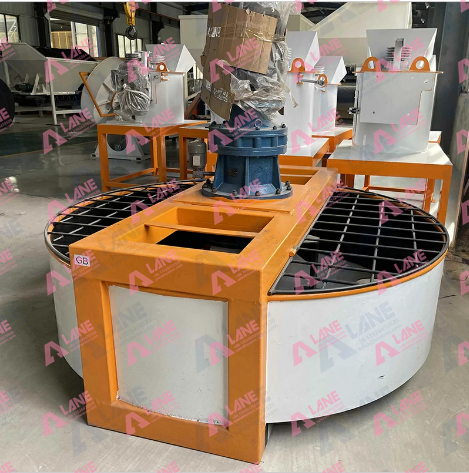

A Disc Mixer, also known as a pan mixer, is a type of industrial mixing equipment that uses a rotating disc to blend various materials. In fertilizer production, it is used to mix different raw materials, such as organic matter, minerals, and additives, into a uniform mixture that can be further processed into granules or other forms of fertilizer.

Key Feature

The disc mixer has very strong radial displacement and dispersion force.When the blade rotates,a vortex will be formed in the container,causing the material to form a low-resistance cyclic tumbling in the cylinder, thereby achieving a fast and uniform mixing effect. The disc mixer can be equipped with a jacket as needed to achieve heating or cooling of materials.

LANE Disc Mixer is designed with several advanced features that ensure optimal mixing performance:

- High Mixing Efficiency: The Disc Mixer’s design allows for rapid and thorough mixing of materials. The rotating disc ensures that all components are evenly distributed, resulting in a homogeneous blend that is crucial for consistent fertilizer quality.

- Robust Construction: Built with high-quality materials, LANE Group’s Disc Mixer is designed to withstand the rigors of industrial use. Its durable construction ensures long-lasting performance, even in demanding production environments.

- Adjustable Mixing Speed: The mixer is equipped with adjustable speed settings, allowing operators to control the intensity of the mixing process. This flexibility ensures that different types of materials can be mixed according to their specific requirements.

- Uniform Discharge: The Disc Mixer is designed for uniform discharge of the mixed materials, ensuring that the blend is consistent from batch to batch. This consistency is key to producing high-quality fertilizer products.

- Energy Efficiency: LANE Group’s Disc Mixer is engineered to be energy-efficient, reducing power consumption while maintaining high levels of performance. This not only lowers operational costs but also supports sustainable manufacturing practices.

- Easy Maintenance: The mixer is designed for easy cleaning and maintenance, with accessible components that can be quickly serviced or replaced. This reduces downtime and keeps the production line running smoothly.

Application

LANE Disc Mixer is versatile and can be used in various stages of fertilizer production:

- Pre-Granulation Mixing: Before materials are granulated, they need to be thoroughly mixed to ensure that the nutrients are evenly distributed. The Disc Mixer is ideal for this stage, preparing the mixture for the granulation process.

- Organic Fertilizer Production: In organic fertilizer production, the Disc Mixer is used to blend organic materials such as composted manure, crop residues, and other organic matter with additional nutrients or additives, ensuring a balanced nutrient profile in the final product.

- Compound Fertilizer Production: The Disc Mixer is also used in the production of compound fertilizers, where different nutrient sources are mixed to create a fertilizer with a specific nutrient composition.

- Bulk Blending Fertilizer Production: For bulk blending fertilizer, where different types of granular fertilizers are mixed, the Disc Mixer ensures that each component is evenly distributed, preventing segregation during application.

Benefit

Incorporating LANE Disc Mixer into your fertilizer production line offers several significant benefits:

- Simple Structure: Easy to install and maintain and operate smoothly and reliably.

- Enhanced Product Quality: The uniform mixing provided by the Disc Mixer ensures that each batch of fertilizer is consistent in nutrient content, leading to a high-quality final product that meets the specific needs of crops.

- Increased Production Efficiency: The Disc Mixer’s high mixing efficiency reduces the time required to prepare materials for further processing, increasing overall production efficiency and throughput.

- Cost Savings: The energy-efficient design of the Disc Mixer helps reduce power consumption, leading to cost savings in the long run. Additionally, the mixer’s durability and ease of maintenance minimize downtime and repair costs.

- Flexibility in Production: The adjustable speed settings and ability to handle different materials make the Disc Mixer a versatile tool that can be used in various fertilizer production processes, from organic to compound fertilizers.

LANE Group disc mixers are key components in the production of high-quality fertilizers. Their advanced design, high mixing efficiency and robust construction ensure that raw materials are thoroughly and evenly mixed to produce a consistent, reliable fertilizer product. Whether you produce compound fertilizers or a variety of phosphate fertilizers, LANE disc mixers are an investment in quality and efficiency that will help you meet the demands of modern agriculture with confidence.

Our Service

If you want get more imformation about this, Contact us!

Latest Articles & Tips

More-

09/13

read morePotash Fertilizer Production Line Efficiency: 5 Key Technologies You Should Know

-

09/11

read more6 Strategies to Maximize Output with a Triple Superphosphate Fertilizer Production Line

-

10/29

read moreHow to Optimize Raw Material Mixing for Higher Output in SSP Production

-

01/29

read more