Disc Granulator

The Disc Granulator is a vital piece of equipment in fertilizer production, particularly for producing granulated fertilizers such as compound and organic fertilizers. Known for its high efficiency and precision, this machine is engineered to convert powdered raw materials into uniformly sized granules, which are easier to apply in agriculture.

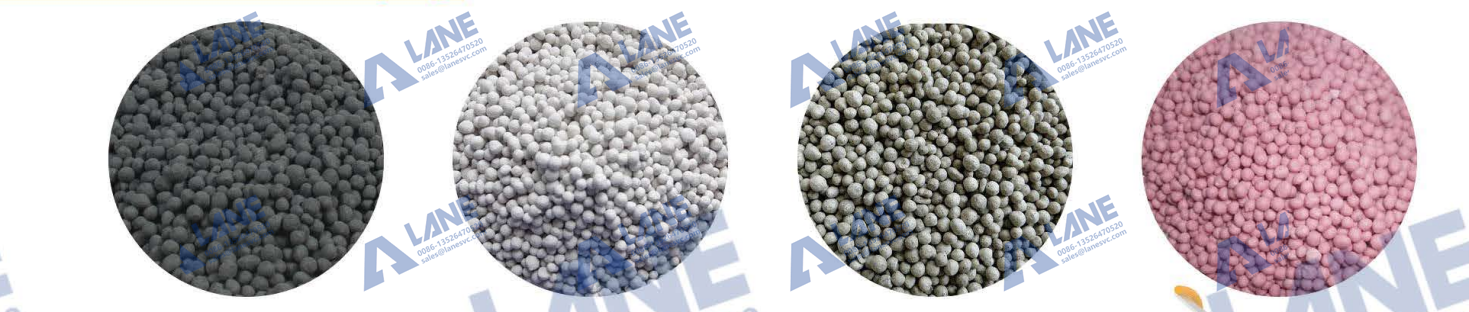

The disc granulator has wide adaptability to raw materials and is widely used in the processing of various fertilizers. It can be used to process organic fertilizer spherical particles, such as coal powder, cement, clinker, chemical fertilizers and other materials. It can also be used in compound fertilizer, chemical industry, It can granulate various raw materials such as feed, coal, metallurgy, etc., and can produce various a concentrations and types of compound fertilizers.

Disc granulator has a wide range of applications, not only can be used in organic fertilizer production line, compound fertilizer production line and other fertilizer production line, but also

can make cat litter and other material particles.

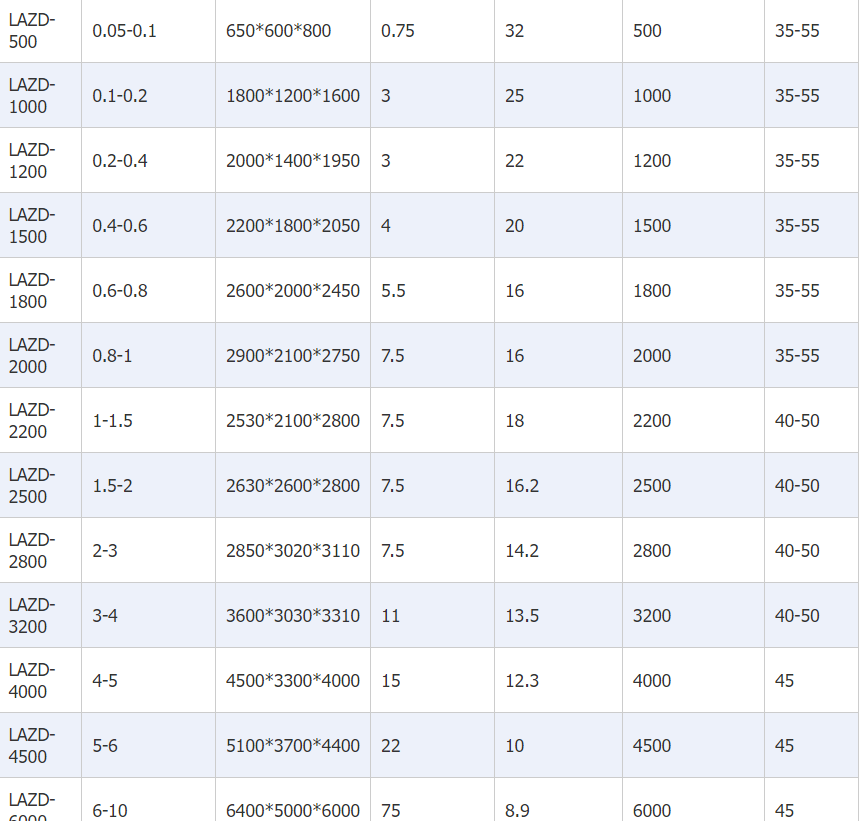

As an experienced fertilizer machinery manufacturer, we offer a vast range of models and component materials for customers to choose from, striving to meet all their expectations!

Working Principle of a Disc Granulator

- Feed Material: The process begins with the feeding of powdered or fine materials into the disc granulator. These materials can include fertilizers, minerals, or other substances that need to be granulated.

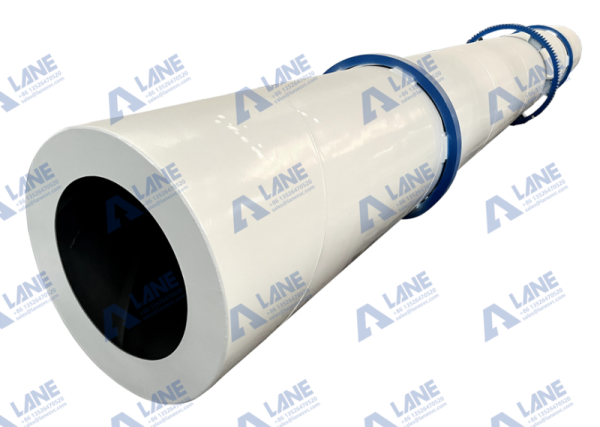

- Disc Rotation: The core component of the granulator is a large, inclined disc or plate that rotates around a central axis. The disc is typically made of durable materials like steel to withstand the friction and impact during operation.

- Material Flow: As the disc rotates, the powdered material is distributed across its surface. The inclined angle of the disc ensures that the material moves from the center towards the edges.

- Granulation Process: The rotation of the disc causes the fine particles to collide and adhere to each other, forming larger granules. This happens due to the centrifugal force generated by the rotation and the continuous agitation of the material. In some cases, a binder or liquid may be added to facilitate the agglomeration process and improve the granules’ quality.

- Granule Formation: As the material moves outward on the disc, it continues to be subjected to shear forces and collisions. These forces help in the formation and growth of granules. The size and quality of the granules can be adjusted by modifying the rotation speed, the inclination angle of the disc, and other operational parameters.

- Discharge: Once the granules reach the desired size, they are collected from the outer edge of the disc. The granules can then be further processed or used directly, depending on the application.

- Optional Features: Some disc granulators may include features like adjustable scraper blades to help in the removal of the finished granules, and spray systems to add binders or moisture.

Finished Products Display

Advangtage

A disc granulator can be used to make fertilizer, cat litter, and other materials. As an experienced fertilizer machinery manufacturer, we offer a wide range of models and materials for customers to choose from.

- The granulating disk has an arc structure and a high granulation rate of over 93%.

- The speed reducer and motor use a flexible belt transmission, which makes it easier to start, slower to slow down, and lasts longer.

- The bottom of the granulating disc is made of durable, never deforms steel.

- The thickened, strong base design is durable and smooth to operate. The main gear of the granulator has a long service life.

- The machine has even granulation, a high rate of ball formation, stable operation, durable equipment, and a long service life. The disc granulator is highly praised by users.