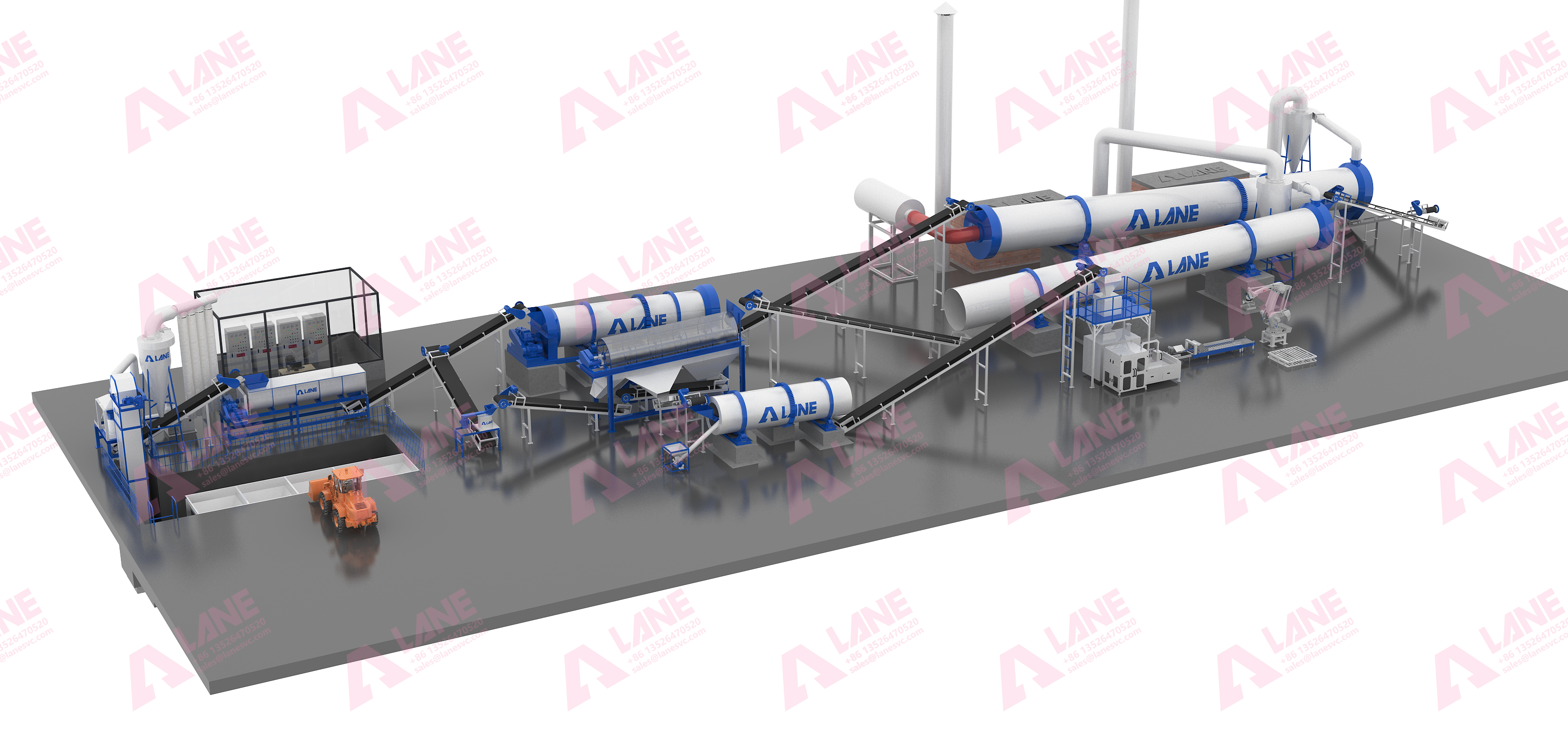

DAP Fertilizer production line

In the global fertilizer industry, our Diammonium Phosphate (DAP) Production Line slashes operating costs by 20% and guarantees 95% granulation rate – your key to unmatched profitability.

Core Advantages

✅ $15–25/ton Cost Savings: Smart neutralization + heat recycling tech cut energy use by 30% and boost raw material efficiency to 95%+.

✅ Flexible Formulas: Adjust N-P₂O₅-K₂O ratios (e.g., 18-46-0, 16-48-0) for global market demands.

✅ Zero-Emission Compliance: 99.5% exhaust purification meets EU IPPC & US NSPS standards.

Why Choose Us?

⚡ 35% Faster ROI: From design to production in 6–9 months (industry avg: 12–15 months).

⚡ Modular Scalability: Customize capacity from 10TPH to 100TPH – expand seamlessly, reduce risks.

⚡ Smart Maintenance: 5-year warranty + IoT real-time monitoring with <2-hour response.

⚡ Global Support: On-site engineers in South America, Southeast Asia & Middle East + 72-hour spare parts delivery.

The production process of Di-ammonium phosphate involves reacting phosphoric acid with ammonia, followed by cooling, grinding and sieving. It can be obtained by the slurry method or the traditional method, in which the slurry method directly uses dilute phosphoric acid produced by the wet method as raw material, ammoniates it in a neutralization tank or a rapid ammoniation evaporator, and then evaporates and concentrates the neutralized slurry to reduce the water content, and then makes Di-ammonium phosphate in granular form by spraying slurry pelletizing and drying, or makes powdered Di-ammonium phosphate by spray drying and fluidized pelletizing and drying.

Production Process

- Raw Material Preparation: Phosphoric acid and ammonia are the primary raw materials.

- Neutralization: Phosphoric acid is reacted with ammonia to form a slurry of DAP.

- Granulation: The slurry is granulated to form uniform DAP particles.

- Drying and Cooling: The granules are dried and cooled to achieve the desired moisture content.

- Screening and Packaging: The granules are screened for size consistency, then packaged for distribution.

Advantage

Here are several key advantages of the LANE Group Di-ammonium Phosphate (DAP) Production Line:

- Advanced Technology: Utilizes cutting-edge technology to ensure efficient and consistent production of high-quality DAP.

- High Output Capacity: Designed to handle large-scale production, meeting the demands of extensive agricultural operations.

- Energy Efficiency: Incorporates energy-saving processes, reducing operational costs and environmental impact.

- Comprehensive Quality Control: Strict quality assurance measures are in place to maintain the superior quality of the DAP produced.

- Customizable Solutions: The production line can be tailored to meet specific production requirements and local market needs.

About Us

Henan Lane Heavy Industry Machinery Technology Co, Ltd.is a fertilizer industry leader and a machine supplier for Africa’s 100000 ton annual national fertilizer project, We have professional experience in manufacturing fertilizer production equipment which can help customers effectively solve the production problems of organic fertilizer, NPK compound fertilizer, biomass fertilizer, mineral fertilizer and BB fertilizer, Henan Lane Heavy Industry Machinery Technology Co., Ltd. supports third-pay factory inspection, with a five-year warranty, and provides customers with free granulation experiments and overseas installation services. It also has a professional overseas after-sales team and over 120 real cases of national fertilizer production lines.

Our Certificate

Real-Life Shipping Cases of Our Products

Welcome customers from all over the world to visit and inspect factories and fertilizer production lines. LANE looks forward to working with you!

Contact Us for more detils.

Latest Articles & Tips

More-

09/23

Improving Efficiency in Di Calcium Phosphate Production with Modern Equipment

read more -

01/26

read more -

09/09

read moreGlobal Potassium Sulfate Demand Growth: The Importance of Sulphate of Potash Production Line Equipment Selection

-

09/13

read moreThe Science Behind Phosphate Production Line: Driving Efficiency and Growth