How Temperature and Pressure Affect DAP Production Quality?

Diammonium phosphate (DAP) is one of the most widely used fertilisers due to its high nutrient content, providing both nitrogen (N) and phosphorus (P), which are essential for plant growth. In the DAP production process, several factors influence the quality of the final product, but two of the most critical parameters are temperature and pressure. Proper management of these conditions can have a significant impact on the granulation process, nutrient retention and overall of DAP production quality.

Temperature is a critical factor in the chemical reaction and granulation stages of DAP production. During the reaction stage, ammonia gas combines with phosphoric acid to form ammonium phosphate. The temperature during this stage must be carefully controlled to ensure a complete reaction and to prevent unwanted by-products that can degrade the DAP production quality.

- Optimal Reaction Temperature

It is essential to maintain an optimal reaction temperature, typically between 150°C and 180°C, to ensure efficient reaction of the ammonia and phosphoric acid. If the temperature is too low, the reaction will be incomplete, resulting in a product with lower nutrient content and inconsistent quality. Conversely, excessively high temperatures can cause overheating, leading to the decomposition of ammonium phosphate and the release of toxic gases, reducing DAP production quality.

Hot Stove

- Granulation Temperature

It is important to note that temperature also plays a critical role in the granulation phase, as it affects the formation of durable, evenly sized granules. The temperature is typically maintained at around 90°C to 120°C to ensure effective particle binding. If the temperature is not within the specified range, the granules may exhibit undesirable characteristics. If the temperature is too high, the granules may become soft and sticky. Conversely, if the temperature is too low, the granules may become brittle and prone to breaking. Both scenarios have an adverse effect on the quality of DAP production, resulting in a product that is less effective when applied.

Impact of Pressure on DAP Production Quality

It’s so important to get the pressure right, especially when it comes to granulation and drying in DAP production. Getting the pressure levels just right will help you to achieve the best possible granule formation and product quality.

- Pressure During Granulation

Proper pressure is the key to achieving uniform granule size and optimal compaction! If you want your granules to be strong and stable, you need to make sure you apply the right amount of pressure. If you don’t, they won’t compact properly and could even break apart during storage or transportation. On the other hand, high pressure can cause over-compaction, making the granules too dense. This affects their solubility and the ability of plants to absorb nutrients efficiently, which is an exciting area for further research! It’s so important to get the balance right! If you’re too high, you’ll compromise the strength of the granules and the quality of the DAP. If you’re too low, you’ll affect the nutrient delivery.

- Drying and Cooling Pressure

Once the granulation process is complete, the DAP granules are dried and cooled under controlled pressure. This is an important step as it helps to remove any excess moisture, ensuring the granules are ready for the next stage! The right pressure is the key to maintaining the structural integrity of the granules while ensuring the product is perfectly dry for storage. It’s so important to get the pressure right during these stages! If it’s too high, the granules will be overly dry or overly moist, which affects both the storage life and the nutrient release efficiency of the fertiliser. This ultimately impacts DAP production quality, so it’s really crucial to get it just right!

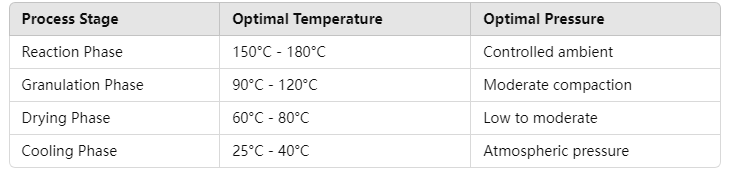

Optimal Temperature and Pressure Control for Superior DAP Production Quality

Maintaining optimal temperature and pressure in DAP production is key to producing high-quality fertilizer. The table below outlines the recommended temperature and pressure ranges in different stages of the production process:

By adhering to these parameters, producers can ensure that the DAP granules are formed correctly, with optimal nutrient content, structural integrity, and solubility.

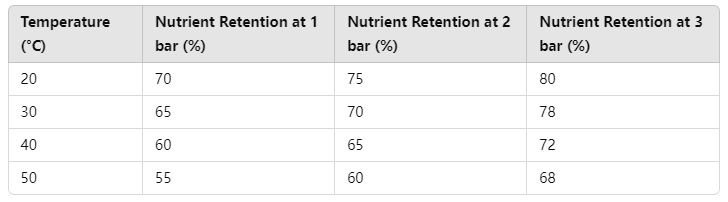

Influence of Temperature and Pressure on Nutrient Retention

DAP is an amazing fertilizer that can really make a difference in your garden! The key to its effectiveness is its nutrient content, especially nitrogen and phosphorus. It’s so important to maintain the right temperature and pressure throughout the production process. This helps to keep all those precious nutrients in their most bioavailable forms! It’s important to keep an eye on the temperature and pressure when using ammonium phosphate compounds. If you do, you’ll find that they’re highly effective at releasing nutrients into the soil!

However, extreme temperatures can degrade these compounds, while inappropriate pressure can compromise the physical structure of the granules. This reduces their ability to release nutrients effectively in the soil.

Enhancing DAP Production Quality through Modern Controls

To consistently produce high DAP production quality, manufacturers are embracing modern technologies such as automated temperature and pressure control systems, and the results are impressive! These incredible systems use real-time sensors to monitor production conditions, adjusting the parameters as needed to maintain optimal levels. This amazing technology doesn’t just improve DAP production quality, it also enhances energy efficiency and reduces production waste!

The fantastic thing about automated systems is that they can respond to fluctuations in the production process, ensuring that conditions remain within the ideal range for producing granules with the correct size, strength, and nutrient content. This is great news for the environment and your bottom line! It minimises the risk of producing substandard fertilizer batches and reduces the costs associated with product reprocessing or wastage.

Conclusion

The DAP production quality is an exacting one, with temperature and pressure control playing a vital role in achieving the highest quality product. Achieving the optimal temperature is key to ensuring a complete chemical reaction, proper granule formation and nutrient retention. And correct pressure is essential for producing strong, uniform granules that meet industry standards! By implementing cutting-edge monitoring and control systems, manufacturers can maintain the perfect conditions for a more efficient production process, a higher-quality product and an improved performance of the fertiliser in the field.

Properly managed temperature and pressure not only enhance the physical properties of DAP but also ensure that its nutrient delivery capacity remains high, benefiting both farmers and the environment.

Send a message to us