Optimize Raw Material Feeding System

Efficient feeding of raw materials into the DAP fertilizer maker is the first crucial step to improving overall output. The quality and consistency of raw materials like ammonia and phosphoric acid directly impact the final product.

Tips for Optimization:

- Automate Material Feeding: Implement an automated feeding system that regulates the flow of materials precisely, reducing manual errors and ensuring a steady, uninterrupted supply.

- Monitor Raw Material Quality: Conduct regular inspections and quality control tests on raw materials to ensure they meet the required standards. Impurities or inconsistencies in raw materials can negatively affect the production process and final product quality.

By optimizing the feeding process, you can reduce waste and ensure consistent production rates.

Granulation is a critical step in DAP fertilizer maker as it transforms the liquid mixture of ammonia and phosphoric acid into solid, uniform granules. This step directly affects the quality and size distribution of the final product.

Granulation Improvements:

- Upgrade Granulation Equipment: Consider investing in advanced rotary drum granulators or disc granulators that offer better control over granule size and shape, ensuring uniform distribution.

- Control Moisture Levels: Implement moisture control systems to maintain the ideal moisture content in the granules, improving the overall quality of the DAP fertilizer maker.

Efficient granulation increases the consistency of granules, which is essential for easy handling, storage, and application by farmers.

The drying and cooling stages are vital for stabilizing the granules and ensuring the DAP fertilizer has the right moisture content in the DAP fertilizer maker process. Proper drying prevents caking, while cooling stabilizes the granules for longer storage.

Key Considerations:

- Use Energy-Efficient Dryers: Rotary drum dryers are commonly used in DAP production lines. Opt for dryers with heat recovery systems to reduce energy consumption and operational costs.

- Implement Advanced Cooling Technology: A well-optimized rotary cooler can rapidly reduce the temperature of granules without damaging their structure. This is crucial to avoid degradation of the nutrients in the fertilizer.

By optimizing the drying and cooling process, you can improve product stability and extend the shelf life of the DAP fertilizer.

Upgrade Material Handling Systems

Efficient handling and transportation of raw materials and final products within the DAP fertilizer maker line are essential for maximizing output. Poor handling can lead to spillage, contamination, and delays in production.

Material Handling Upgrades:

- Install Conveyor Systems: Invest in high-quality belt conveyors, bucket elevators, or screw conveyors to transport raw materials and granules between different stages of production smoothly and efficiently.

- Automate Material Transfer: Automation of material transfer minimizes manual intervention, reduces human errors, and accelerates the production process, leading to higher output.

Optimized material handling improves the speed and efficiency of production while reducing downtime.

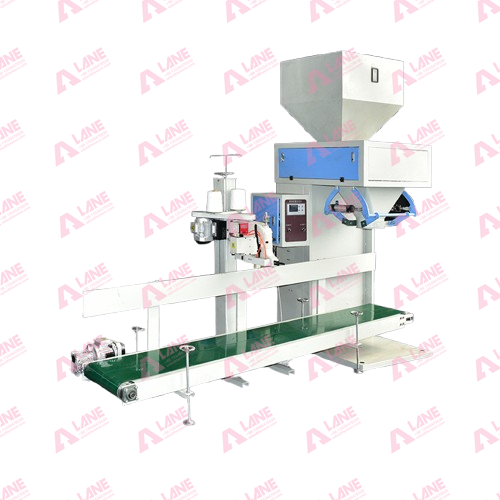

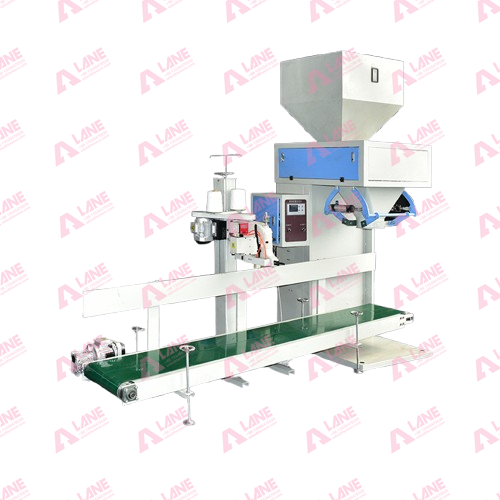

Automate the Packaging Process

Once the DAP granules are produced, they need to be efficiently packaged for distribution. An automated packaging system is essential to maintain production speed and reduce bottlenecks.

Packaging Optimization:

- Automated Weighing and Sealing: Implement automated packing machines that can weigh and seal the fertilizer with high precision. This ensures that each package contains the right amount of fertilizer without delays.

- Use Durable Packaging Materials: Ensure that the packaging materials used are durable enough to protect the fertilizer during transportation and storage, preventing any product losses.

Automating the packaging process can significantly boost the speed of production and minimize manual labor.

Implement Continuous Quality Control

To consistently achieve higher output, it’s critical to maintain high product quality throughout the production process. Continuous monitoring and quality control measures are essential for identifying potential issues before they impact output.

Quality Control Practices:

- Real-Time Monitoring: Install sensors and automated systems that continuously monitor key parameters such as temperature, moisture, and nutrient composition at every stage of production.

- Regular Testing: Conduct frequent tests on the DAP fertilizer granules to ensure they meet industry standards for nutrient content, size, and moisture.

By maintaining strict quality control, you can ensure that production output is not compromised by defects or inconsistencies.

Regular Maintenance and Upgrades

Lastly, one of the most important steps in optimizing your DAP fertilizer maker for higher output is regular maintenance of equipment and periodic upgrades to newer technologies.

Maintenance and Upgrade Strategies:

- Schedule Preventive Maintenance: Regularly inspect and service critical components like granulators, dryers, coolers, and conveyors to avoid unexpected breakdowns that can halt production.

- Upgrade to Energy-Efficient Systems: Consider upgrading older equipment to more energy-efficient models. This not only reduces operational costs but also increases production efficiency and output.

Well-maintained and upgraded machinery ensures a smoother DAP fertilizer maker, reduces downtime, and maximizes output.

Conclusion: Maximize DAP Fertilizer Production for Higher Yields

By following these seven optimization steps, manufacturers can significantly increase the output of their DAP fertilizer production line while maintaining product quality. From upgrading the DAP fertilizer maker to automating packaging and enhancing material handling systems, each step plays a vital role in improving productivity. Implementing continuous quality control and ensuring regular maintenance further boosts the efficiency and output of the production line, ultimately benefiting both manufacturers and farmers.

With the global demand for high-quality fertilizers like DAP on the rise, optimizing production lines is crucial to meeting market demands and supporting the agricultural industry.

Do you want to get more imformation?

Click to watch more videos!

Click to Contact us!

Send a message to us