Revolutionizing Crop Production: The DAP Agri Fertilizer Production Line Explained

As the global population continues to grow and agricultural demands increase, the need for efficient and effective fertilizers has never been more critical. Among the various fertilizers available, Diammonium Phosphate (DAP) stands out as a key player in enhancing crop production. The DAP Agri Fertilizer Production Line is central to this process, transforming raw materials into high-quality fertilizers that provide essential nutrients for plant growth.

In this article, we will explore the workings of the DAP Agri Fertilizer Production Line, its benefits, and its significance in modern agriculture.

The Importance of DAP Fertilizers

DAP fertilizers are rich in phosphorus and nitrogen, two of the three essential macronutrients required for plant growth. Phosphorus plays a crucial role in root development, energy transfer, and photosynthesis, while nitrogen is vital for leaf and stem growth. DAP fertilizers deliver these nutrients in a readily available form, making them particularly effective for promoting healthy crop establishment and increasing yields.

Farmers often turn to DAP fertilizers to address nutrient deficiencies in their soils, especially in regions where phosphorus is limited. By ensuring that crops receive adequate amounts of these essential nutrients, DAP fertilizers contribute to improved crop quality and higher agricultural productivity.

How the DAP Agri Fertilizer Production Line Works

The production of DAP fertilizers involves several key steps, each utilizing specialized machinery to ensure efficiency and quality. Here’s an overview of how the DAP Agri Fertilizer Production Line operates:

a. Raw Material Preparation

The process begins with the careful selection and preparation of raw materials, primarily phosphate rock and ammonia. Phosphate rock is mined, crushed, and processed to increase its surface area, while ammonia is sourced from natural gas or other nitrogen-rich materials.

b. Acidulation Process

The core of the DAP Agri Fertilizer Production Line is the acidulation process, where phosphate rock is reacted with sulfuric acid to produce phosphoric acid. This reaction is crucial for converting the raw phosphate into a form that can be further processed into DAP:

Ca3(PO4)2+2H2SO4→2H3PO4+3CaSO4

This phosphoric acid is then combined with ammonia in a subsequent reaction to produce DAP:

H3PO4+2NH3→(NH4)2HPO4

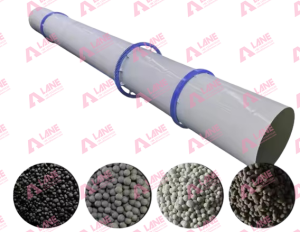

c. Granulation

After the acidulation process, the resulting DAP mixture is granulated to form uniform granules. Granulators are used to compact the mixture, ensuring that each granule has the desired nutrient content and size. This step is critical for making the fertilizer easy to handle, transport, and apply.

d. Drying and Cooling

Once granulated, the DAP fertilizer must be dried to remove excess moisture, which can affect its stability and performance. Drying machines use hot air to achieve the desired moisture content. After drying, the granules are cooled to prevent clumping during storage.

e. Screening and Packaging

The final step involves screening the granules to ensure uniform size and quality. Oversized or undersized particles are removed to maintain product consistency. Once the fertilizer passes quality control checks, it is packaged into bags or bulk containers for distribution.

Benefits of the DAP Agri Fertilizer Production Line

Investing in a DAP Agri Fertilizer Production Line offers numerous advantages for manufacturers and farmers alike:

a. High Efficiency and Productivity

Modern DAP production lines are designed for high efficiency, enabling manufacturers to produce large quantities of fertilizers quickly. Automated systems streamline the production process, reducing labor costs and improving overall productivity.

b. Customizable Fertilizer Blends

The flexibility of DAP production lines allows manufacturers to create customizable fertilizer blends tailored to specific crop needs. By adjusting the nutrient ratios, producers can cater to the requirements of various plants, ensuring optimal nutrient delivery.

c. Enhanced Nutrient Availability

DAP fertilizers are highly soluble, providing a quick source of nutrients for plants. The efficient manufacturing process of the DAP Agri Fertilizer Production Line ensures that the final product is optimized for maximum nutrient availability, promoting healthy plant growth and increased yields.

d. Environmental Considerations

By producing DAP fertilizers, manufacturers can contribute to sustainable agricultural practices. Proper management of raw materials and adherence to environmental regulations can minimize the impact of fertilizer production on the environment. Moreover, DAP fertilizers can help improve soil health over time, supporting a more sustainable farming system.

The Future of DAP Fertilizer Production

As agricultural practices continue to evolve, the demand for effective fertilizers like DAP will remain strong. Innovations in production technology, such as automation, data analytics, and precision agriculture, will play a critical role in enhancing the efficiency and sustainability of DAP fertilizer manufacturing.

Future advancements may include:

- Smart Production Systems: Integrating IoT devices for real-time monitoring and optimization of the production process.

- Sustainable Sourcing: Increasing the use of renewable resources and waste materials in fertilizer production to enhance sustainability.

- Precision Formulation: Utilizing data-driven approaches to create highly targeted fertilizer blends based on specific soil and crop needs.

Conclusion

The DAP Agri Fertilizer Production Line is essential for meeting the growing nutritional needs of crops in an increasingly demanding agricultural environment. By providing a reliable source of phosphorus and nitrogen, DAP fertilizers play a crucial role in enhancing agricultural productivity and supporting sustainable farming practices.

As technology continues to advance, the potential for improving DAP fertilizer production becomes even greater. By investing in modern production lines and embracing innovative practices, manufacturers can contribute to a more resilient agricultural sector that supports global food security while minimizing environmental impact.

Send a message to us