The Role of Crusher Machines in TSP Fertilizer Manufacturing

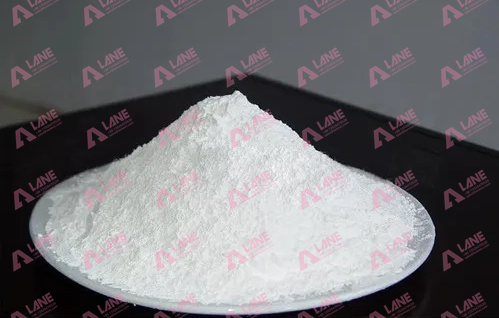

Triple Superphosphate (TSP) fertilizer is an essential product for agricultural industries worldwide, providing a concentrated source of phosphorus crucial for crop growth and soil enrichment. The manufacturing process of TSP fertilizer involves multiple stages, each requiring precision and efficiency. One of the most critical components in this process is the crusher machine, which ensures the proper preparation of raw materials.

The Function of Crusher Machines in TSP Manufacturing

Crusher machines play a vital role in the early stages of TSP fertilizer production by breaking down raw phosphate rock and other materials into smaller, manageable sizes. This crushing step ensures the materials are suitable for further processing, such as mixing with acid to produce the TSP fertilizer.

Key Roles of Crusher Machines in TSP Fertilizer Manufacturing:

- Size Reduction

Raw phosphate rock is typically mined in large chunks that are unsuitable for direct processing. Crusher machines reduce these rocks into smaller particles, creating a uniform input material for subsequent stages. - Improved Chemical Reaction Efficiency

The surface area of raw phosphate material directly affects its reaction with sulfuric acid during the production of TSP. By reducing the size of the raw material, crusher machines enhance the material’s surface area, ensuring more efficient and thorough chemical reactions. - Prevention of Equipment Damage

Unprocessed rocks can damage machinery downstream, such as mixers or granulators. Crusher machines mitigate this risk by ensuring all materials are of an appropriate size and free of oversized particles. - Consistency in Final Product Quality

Uniformly crushed raw materials lead to consistent production outcomes. Variability in particle size can affect the texture, granule size, and nutrient composition of the final TSP fertilizer.

Types of Crusher Machines in TSP Fertilizer Manufacturing

Different types of crushers are used in TSP fertilizer production, each with its own advantages and applications.

Hammer Crushers

- Function: Ideal for crushing softer phosphate rock into fine powders or small granules.

- Advantages: Highly efficient for producing materials that require minimal subsequent grinding.

Vertical Crushers

- Function: Used for creating even finer particles and ensuring uniform material preparation.

- Advantages: Precise control over particle size distribution.

Cage Crushers

Crusher Machines and Efficiency in TSP Production

Energy Savings

Modern crusher machines are designed with energy efficiency in mind. By incorporating advanced crushing mechanisms and wear-resistant materials, they reduce energy consumption while maintaining high output levels.

Increased Throughput

With the ability to process large volumes of material quickly, crusher machines ensure uninterrupted production cycles, minimizing downtime and maximizing productivity.

Automation and Control

Many crusher machines in TSP fertilizer manufacturing come equipped with automated systems that monitor material size, adjust settings, and ensure optimal performance. This reduces the need for manual intervention and enhances overall efficiency.

Enhancing TSP Quality with Crusher Machines

The role of crusher machines in TSP fertilizer manufacturing extends beyond simply breaking down raw materials. Their performance directly impacts the quality of the final fertilizer product:

- Granule Uniformity

Proper crushing ensures that all raw materials are evenly sized, leading to consistent granules in the final product. - Purity of Fertilizer

By eliminating oversized particles and impurities, crushers help maintain the purity of the TSP fertilizer, which is essential for meeting agricultural standards. - Improved Nutrient Availability

Crushing phosphate rock to the ideal particle size increases the availability of phosphorus in the fertilizer, enhancing its effectiveness in agricultural applications.

Challenges and Solutions in Using Crusher Machines

While crusher machines in TSP machines are indispensable fertilizer manufacturing, they also present challenges that must be addressed:

Wear and Tear

The abrasive nature of phosphate rock can lead to significant wear on crusher components.

- Solution: Use wear-resistant materials like manganese steel or tungsten carbide for crusher parts.

Dust Generation

Crushing phosphate rock can produce large amounts of dust, posing risks to worker safety and equipment functionality.

- Solution: Implement dust suppression systems, such as water sprays or enclosed crushers, to minimize dust.

Material Hardness Variability

Phosphate rock can vary in hardness, making it difficult to achieve consistent crushing results.

- Solution: Use adjustable crusher settings and multiple crushing stages to accommodate material variations.

Future Trends in Crusher Machines for TSP Manufacturing

The role of crusher machines in TSP fertilizer manufacturing is evolving with advancements in technology. Manufacturers are focusing on creating more efficient, durable, and environmentally friendly crushers to meet the demands of modern fertilizer production.

Innovations to Watch:

- Smart Crushers

- Equipped with sensors and AI algorithms to monitor and optimize performance in real time.

- Energy-Efficient Designs

- Crushers with advanced drive systems and reduced energy consumption.

- Modular Systems

- Easily upgradeable crushers that can adapt to changing production needs.

Conclusion

Crusher machines are the backbone of TSP fertilizer manufacturing, ensuring that raw materials are properly prepared for efficient processing and high-quality production. From enhancing chemical reactions to preventing equipment damage, their role is critical to every stage of the manufacturing process.

Investing in advanced crusher machines in TSP fertilizer manufacturing not only improves production efficiency but also ensures that the final product meets the high standards demanded by the agricultural industry. As technology continues to evolve, crusher machines will play an even greater role in driving innovation and sustainability in fertilizer production.

Send a message to us