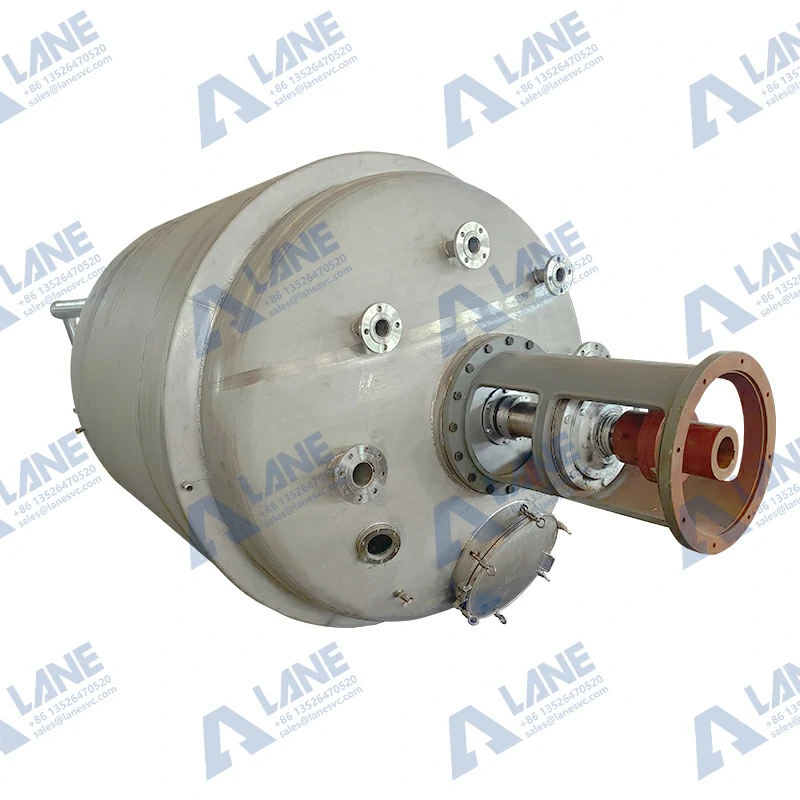

Chemical Fertilizer Reactor

Lane Machinery Group sells high-quality fertilizer reactors. These integrated units combine mixing, reaction, and synthesis functions, serving as critical equipment for producing various fertilizer products including urea, compound fertilizers, ammonium phosphate, and nitrogen fertilizers.

Fertilizer Reactor Overview

The fertilizer reactor is a core reaction vessel meticulously designed by our company for the modern fertilizer industry.

Integrating mixing, reaction, and synthesis functions, it serves as the key apparatus for producing various fertilizer products including urea, compound fertilizers, ammonium phosphate, and nitrogen fertilizers.

Lane’s fertilizer reactors, engineered with advanced design and manufacturing techniques, deliver efficient, stable, safe, and energy-saving solutions for demanding chemical production environments. They represent the ideal choice for enhancing your enterprise’s production efficiency and market competitiveness.

Core Design and Technical Features

1. Superior Material Science and Corrosion-Resistant Structure

Primary Materials: Depending on process requirements, high-grade stainless steel (e.g., 304, 316L), duplex steel, nickel-based alloys (Hastelloy), or carbon steel bodies lined with specialty rubber or glass-lined surfaces can be selected. Ensures equipment withstands long-term erosion from highly corrosive media like ammonia, chloride ions, phosphoric acid, and sulfuric acid, significantly extending service life.

Composite Manufacturing Process: Utilizes advanced welding techniques and heat treatment to ensure a dense, defect-free vessel structure, fundamentally eliminating leakage risks.

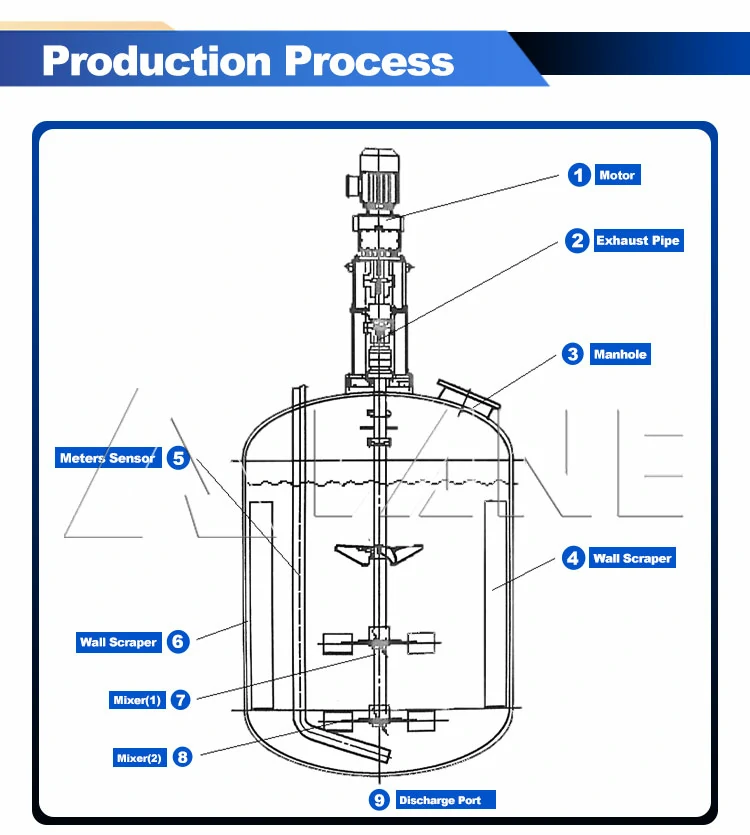

2. High-Efficiency Heat Transfer and Mixing System

Diversified Heat Transfer Design: Standard configurations include jackets, coils, or external half-pipes, supporting steam, thermal oil, or cooling water for rapid heating and precise temperature control. This meets the complex exothermic/endothermic reaction demands of fertilizer synthesis.

Precision Agitation Devices:

Configured with anchor, paddle, turbine, or propeller agitators tailored to the viscosity, density, and reaction characteristics of different fertilizer materials. Ensures thorough mixing without dead zones, achieving uniform and complete reactions to significantly enhance product conversion rates and quality consistency.

3. Advanced Automation and Control System

Integrated Control Solution: Seamlessly integrates with PLC and DCS systems for real-time monitoring and precise automatic control of critical process parameters including temperature, pressure, agitation speed, pH, and liquid level.

Human-Machine Interface: Features a high-definition touchscreen for intuitive operation. Supports presetting, storing, and recalling multiple production recipes, enabling “one-button” production to reduce human error, boost efficiency, and enhance batch stability.

4. Comprehensive Safety Assurance Mechanisms

Multi-layered Safety Protection: Incorporates mechanical safety valves, bursting discs, and pressure/temperature sensor interlock alarms to ensure automatic protective measures during overpressure, overtemperature, or other abnormal conditions.

Complete Process Interfaces: Provides standard interfaces including manholes, sight glasses, sampling valves, vent valves, and explosion-proof devices for convenient operation, maintenance, and inspection, ensuring all-around safety for personnel and equipment.

5. User-Friendly Design and Easy Maintenance

Modular Structure: Key components feature modular design for simplified installation, disassembly, and maintenance, minimizing downtime.

Smooth Surface Finish: Interior walls undergo mirror polishing or electropolishing, achieving ultra-low roughness that resists material buildup and scaling. Easy cleaning effectively prevents cross-contamination between batches.

Key Technical Parameters

- Volume Range: 1,000L – 50,000L (Customizable upon request)

- Design Pressure: Atmospheric – 5.0MPa (or higher)

- Design Temperature: -20°C – 300°C

- Heating Method: Steam, Electric Heating, Thermal Oil

- Agitation Speed: 0-150 rpm (frequency-controlled)

- Sealing Type: Mechanical seal or packing seal, ensuring zero leakage

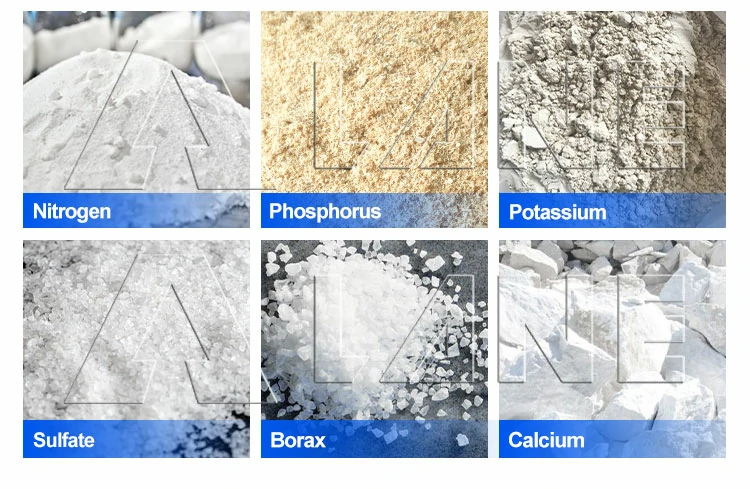

- Applicable Media: Urea solution, ammonia water, phosphoric acid, sulfuric acid, potassium chloride slurry, and various other fertilizer raw materials.

Application Areas

This fertilizer reactor is widely used in the production processes of various fertilizers, including but not limited to:

- Nitrogen Fertilizers: Synthesis of urea, ammonium nitrate, and ammonium bicarbonate

- Phosphate Fertilizers: Production of calcium superphosphate, triple superphosphate, and ammonium phosphates (such as monoammonium phosphate and diammonium phosphate)

- Compound Fertilizers: Pre-granulation reactions and blending for sulfur-based and chlorine-based compound fertilizers in various formulations and forms

- Potassium Fertilizers and Novel Fertilizers: Chemical reaction processes for high-end fertilizers such as controlled-release fertilizers and water-soluble fertilizers

Why Choose Our Fertilizer Reactors?

- Tailored Solutions: We deeply understand the complexity of fertilizer processes and provide customized solutions optimized for your specific raw materials, products, and production capacity requirements.

- Quality Commitment: Every step—from raw material procurement to factory testing—strictly follows ISO quality management systems, ensuring each unit meets the highest standards.

- Full-Cycle Service: We provide comprehensive lifecycle support from design and installation to commissioning, operator training, and after-sales maintenance, ensuring your complete peace of mind.

- Economic Benefits: High reaction efficiency combined with low energy consumption and minimal maintenance costs deliver significant return on investment.

Feel free to contact us. Our technical team is always ready to provide professional product selection and solutions.

Lane Machinery Group

Phone/WhatsApp: +86 135-2647-0520

Email: sales@lanesvc.com

Latest Articles & Tips

More-

09/09

read more3 Technical Highlights of LANE SOP Fertilizer Production Line to Ensure Stable Yield Increase

-

09/12

read moreTop 4 Features of a Modern Superphosphate SSP Compound Production Line

-

01/28

read more -

09/20

read moreFrom Soil to Harvest: The Benefits of Potassium Compound Fertilizer in Crop Management