Cage Crusher

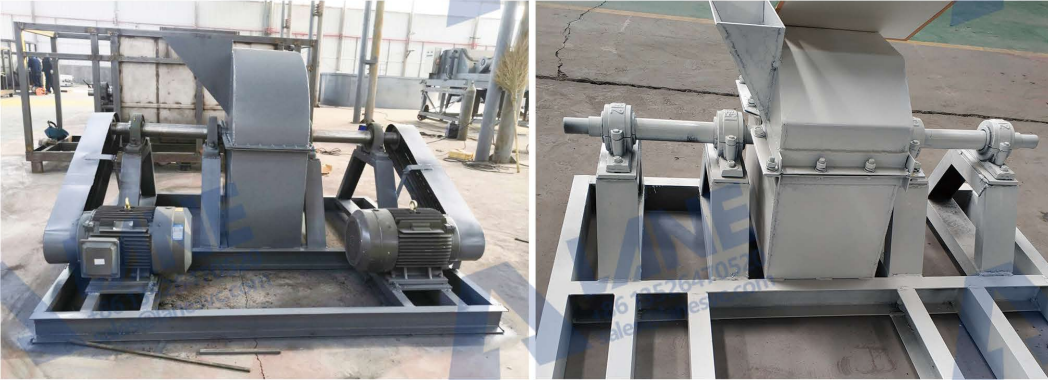

A Cage Crusher is a type of grinding mill that uses high-speed rotating cages to crush and pulverize materials. The machine consists of two rotating cages, each fitted with steel bars or rods, that spin in opposite directions. As the material passes through the cages, it is subjected to impact forces that break it down into smaller particles.

The Cage Crusher is especially effective for crushing brittle materials such as phosphate, gypsum, coal, and a variety of fertilizers. It is designed to produce a fine, uniform particle size, which is crucial for ensuring the quality and performance of the final fertilizer product.

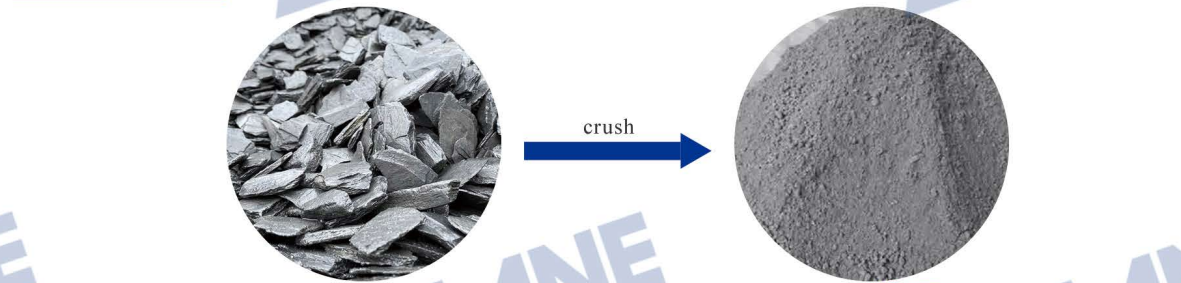

Crushing Process

LANE Cage Crusher is engineered to optimize the crushing process, ensuring maximum efficiency and consistent product quality:

- Material Feeding: The process begins with the feeding of raw materials into the crusher. These materials can include fertilizers, phosphate, gypsum, or other bulk materials that require size reduction.

- High-Speed Rotation and Impact: As the material enters the crusher, it is caught between the two rotating cages. The high-speed rotation of the cages generates a powerful impact force that shatters the material into smaller particles. The cages are designed with a series of steel bars or rods that create a grid-like structure, ensuring that the material is evenly crushed as it passes through.

- Particle Size Control: The size of the final product can be controlled by adjusting the gap between the cages or the speed at which they rotate. This allows for precise control over the particle size, ensuring that the crushed material meets the desired specifications.

- Discharge and Collection: Once the material has been crushed to the desired size, it is discharged from the crusher for further processing or packaging. The final product is a batch of fine, uniform particles that are ideal for use in fertilizer formulations.

Product Video

Advantages

LANE Cage Crusher offers several key advantages that make it an excellent choice for fertilizer production:

- High Crushing Efficiency: The crusher’s dual-cage design ensures that materials are crushed quickly and efficiently, reducing the time and energy required for the size reduction process.

- Uniform Particle Size: The Cage Crusher produces a consistent particle size, which is crucial for ensuring the quality and performance of the final fertilizer product.

- Versatility: The crusher can handle a wide range of materials, including organic, inorganic, and compound fertilizers, making it suitable for various production lines.

- Durable Construction: LANE Group’s Cage Crusher is built with high-quality materials and components, ensuring long-term durability and reliable performance in demanding production environments.

- Easy Maintenance: The crusher is designed for easy maintenance, with accessible components that can be quickly replaced or serviced to minimize downtime.

Applications

The Cage Crusher is widely used in the production of various types of fertilizers and other bulk materials, making it a versatile tool in the agricultural and industrial sectors:

- Phosphate Fertilizers: The crusher is ideal for crushing phosphate materials, ensuring they are finely ground and ready for use in fertilizer formulations.

- Gypsum: The crusher can efficiently handle gypsum, reducing it to a fine powder that can be used in various agricultural and industrial applications.

- Coal: The crusher is effective in crushing coal, preparing it for use in energy production or other industrial processes.

- Organic and Inorganic Fertilizers: The crusher can process a wide range of fertilizers, ensuring they are finely ground and ready for use in agricultural applications.

Finished Product Display