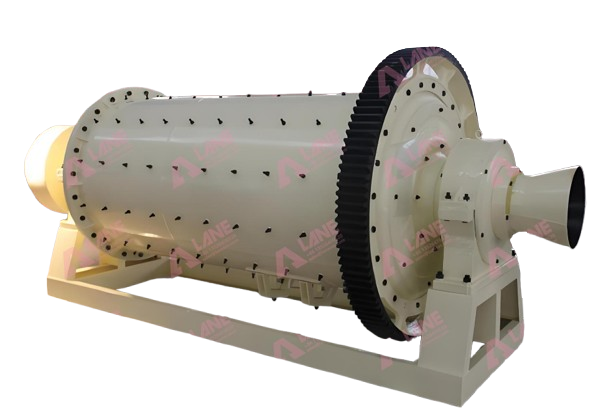

Ball Mill

A Ball Mill is a type of grinder that uses balls as the grinding media. It is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials, and paints. The Ball Mill operates on the principle of impact and attrition, where the balls drop from near the top of the shell, crushing and grinding the material inside.

In the industrial world, where material refinement and precise processing are key to high-quality production, the Ball Mill stands out as an essential piece of equipment. Whether in the production of fertilizers, cement, or other powdered materials, Ball Mill offers a robust solution for grinding and blending materials into fine particles, optimizing the efficiency of subsequent processes.

Working Principle

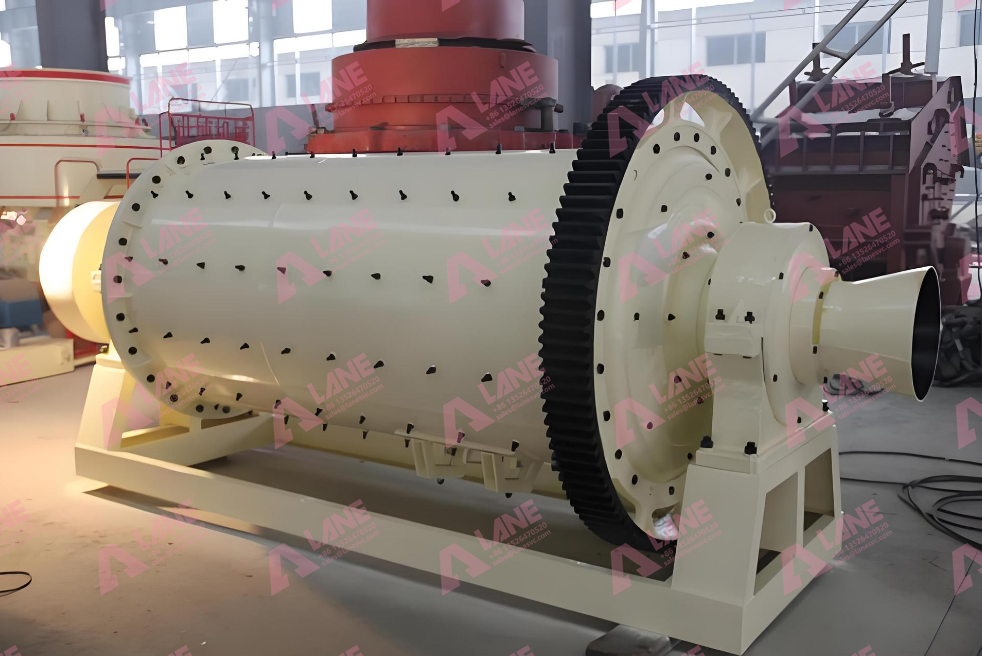

Key Feature

Ball Mill is designed with the following key features that make it an indispensable tool in various industries:

- High Grinding Efficiency: The Ball Mill is engineered to achieve fine and uniform particle sizes, which is essential for ensuring the quality of the end product. Its high grinding efficiency makes it ideal for processing materials that require precise refinement.

- Durable Construction: Built with robust materials, LANE Group’s Ball Mill is designed to withstand the rigors of industrial environments. Its durable construction ensures long-lasting performance and minimal maintenance requirements.

- Versatile Applications: The Ball Mill is versatile, capable of grinding a wide range of materials, including hard minerals, cement, coal, and even organic materials. This versatility makes it a valuable addition to various production lines.

- Energy-Efficient Operation: LANE Group’s Ball Mill is designed to be energy-efficient, reducing operational costs while maintaining high levels of productivity.

- Customizable Design: The Ball Mill can be customized to meet the specific needs of different industries. From varying the size of the drum to adjusting the type of grinding media, LANE Group can tailor the machine to suit specific material processing requirements.

Application

The Ball Mill is widely used across different industries, including:

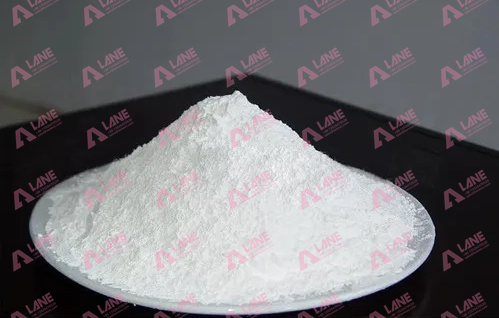

- Fertilizer Production: In fertilizer manufacturing, the Ball Mill is used to grind raw materials such as phosphate rock, limestone, and other minerals into fine powders that are then processed into granules or other forms suitable for agricultural use.

- Cement Manufacturing: The Ball Mill is crucial in the production of cement, where it is used to grind clinker and other raw materials into a fine powder that is then mixed to produce cement.

- Mining and Metallurgy: In the mining industry, the Ball Mill is used to grind ores before they undergo further processing, such as smelting or flotation, to extract valuable minerals.

- Chemical Processing: The Ball Mill is employed in the chemical industry for grinding and mixing chemicals to create homogeneous compounds and facilitate reactions.

Benefit

Incorporating Ball Mill into your production line offers several benefits:

- Improved Product Quality: The fine and uniform particle size achieved by the Ball Mill enhances the quality of the final product, whether it’s fertilizer, cement, or another material.

- Increased Efficiency: The high grinding efficiency of the Ball Mill helps to speed up production processes, increasing overall productivity.

- Cost Savings: With its energy-efficient design and durable construction, the Ball Mill helps to reduce operational and maintenance costs, offering long-term savings.

- Flexibility: The ability to customize the Ball Mill allows manufacturers to tailor it to their specific needs, making it a versatile tool that can adapt to different production requirements.

Our Service

If y0u want to know more, Contact Us!

Latest Articles & Tips

More-

02/13

Chemical Fertilizer Production Line: Enhancing Agricultural Productivity with Precision Manufacturing

read more -

10/17

read morePrecision Farming with Ammonium Sulphate Powder: A Game-Changer in Fertilization

-

01/21

read more -

09/27

Phosphate Fertilizer Production Lines: The Hidden Force Behind Global Food Security

read more